Method for promoting alpha-to-gamma crystal transformation of vinylidene fluoride

A polyvinylidene fluoride and crystal form transformation technology, applied in the field of polyvinylidene fluoride plastic modification, can solve the problems of high technical difficulty, low melting point of gamma crystal and high cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

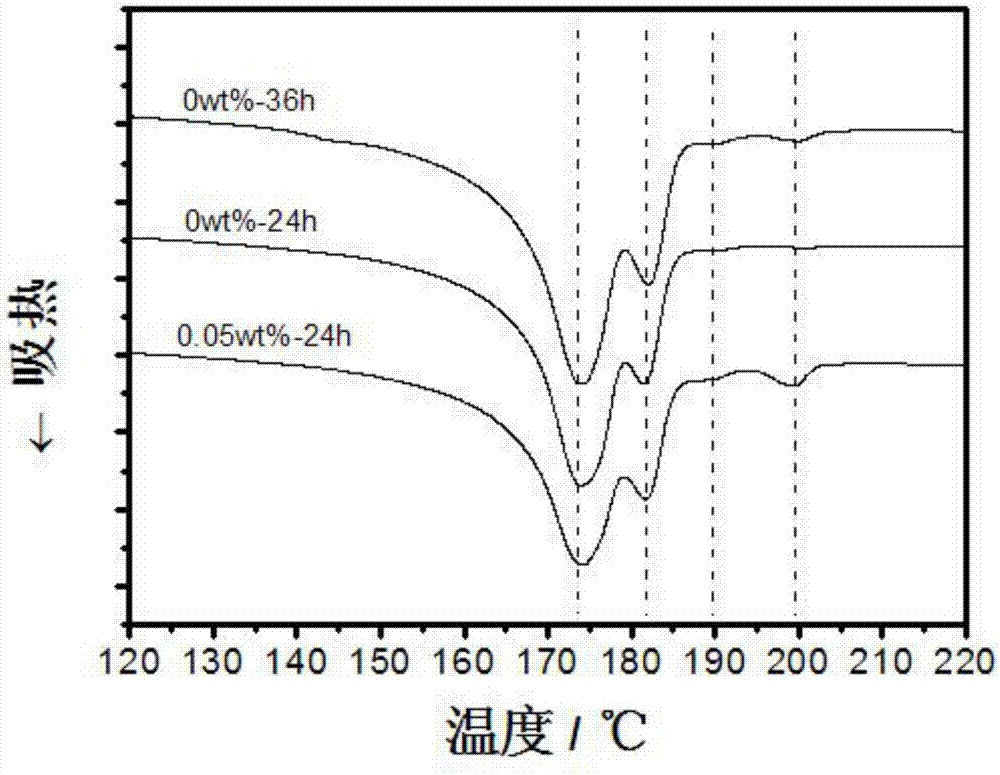

[0018] Add 100g PVDF (Solvay S.A., Brussels, Belgium.) to the banburying chamber of XSS-30 torque rheometer at 230°C, melt and banbury at 230°C for 10min, then add 0.05g graphene (Changzhou Sixth Element Material Technology Co., Ltd., SE1231), continue to melt and knead at 230 ° C for 15 minutes to fully mix graphene and PVDF, take out the tablet after banburying, and obtain a PVDF / graphene composite material. Carry out the same banburying process on PVDF pure material for comparison.

[0019] Add the banburyed PVDF / graphene composite material between the two heating plates of the flat vulcanizer, melt at 230°C for 10 minutes, then gradually pressurize to 30MPa, hold the pressure for 5 minutes, transfer to the cooling plate for holding pressure and shaping, and press to obtain 1mm thick sheet and cut it into a 18mm diameter disc.

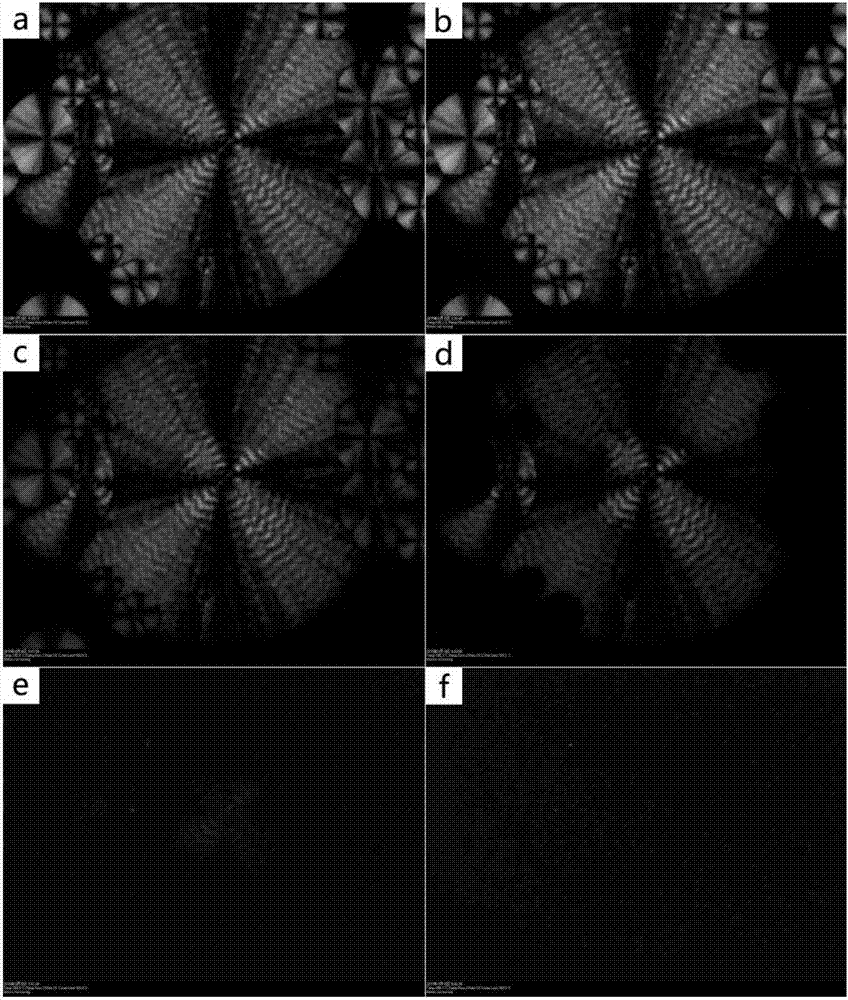

[0020] Put the wafer into the shear cell of the CSS450 shear heat station, and heat up to 230°C at a heating rate of 30°C / min to melt the sample. ...

Embodiment 2

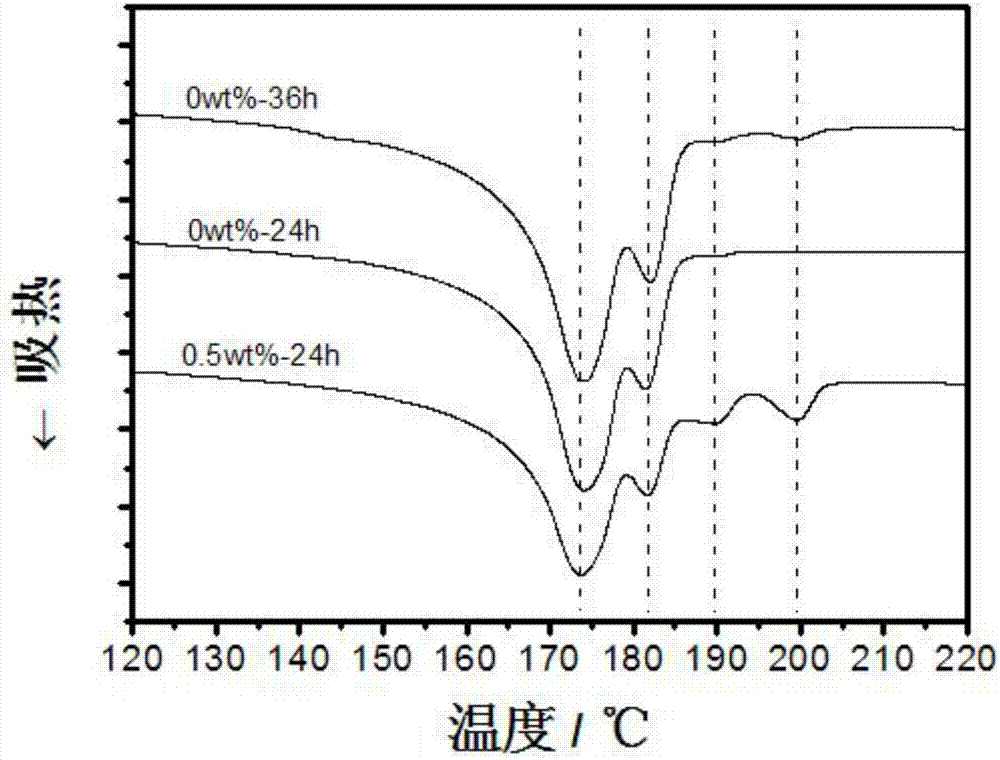

[0022] 100g PVDF (Solvay S.A., Brussels, Belgium.) was loaded into the mixing chamber of XSS-30 torque rheometer at 230°C, and melted and mixed at 230°C for 10min. Then add 0.5g graphene (Changzhou Sixth Element Materials Technology Co., Ltd., SE1231) and melt and knead at 230°C for 15 minutes to fully mix graphene and PVDF. After banburying, take out the tablet to prepare a PVDF / graphene composite Material. Carry out the same banburying process on PVDF pure material for comparison.

[0023] Load the good polyvinylidene fluoride / graphene composite material between the two heating plates of the flat vulcanizer, first melt it at 230°C for 10 minutes, then gradually increase the pressure to 30MPa, hold the pressure for 5 minutes, and then transfer it to the cooling plate for preservation. Press and shape, press into 1mm thick sheet, and it is cut into the disc of diameter 18mm.

[0024] Put the wafer into the shear cell of the CSS450 shear heat station, and heat up to 230°C at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com