Acid in-situ leaching uranium mining laboratory simulation device and test method

A laboratory simulation and in-situ leaching uranium mining technology, which is applied in the field of uranium mining, can solve the problem of incomplete compliance with in-situ leaching uranium field tests and production, and the inability to accurately examine the accumulation of impurity ions, the impact of uranium leaching and ore water permeability, etc. problems, to achieve the effect of reducing the risk of mine blockage and improving the level of prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

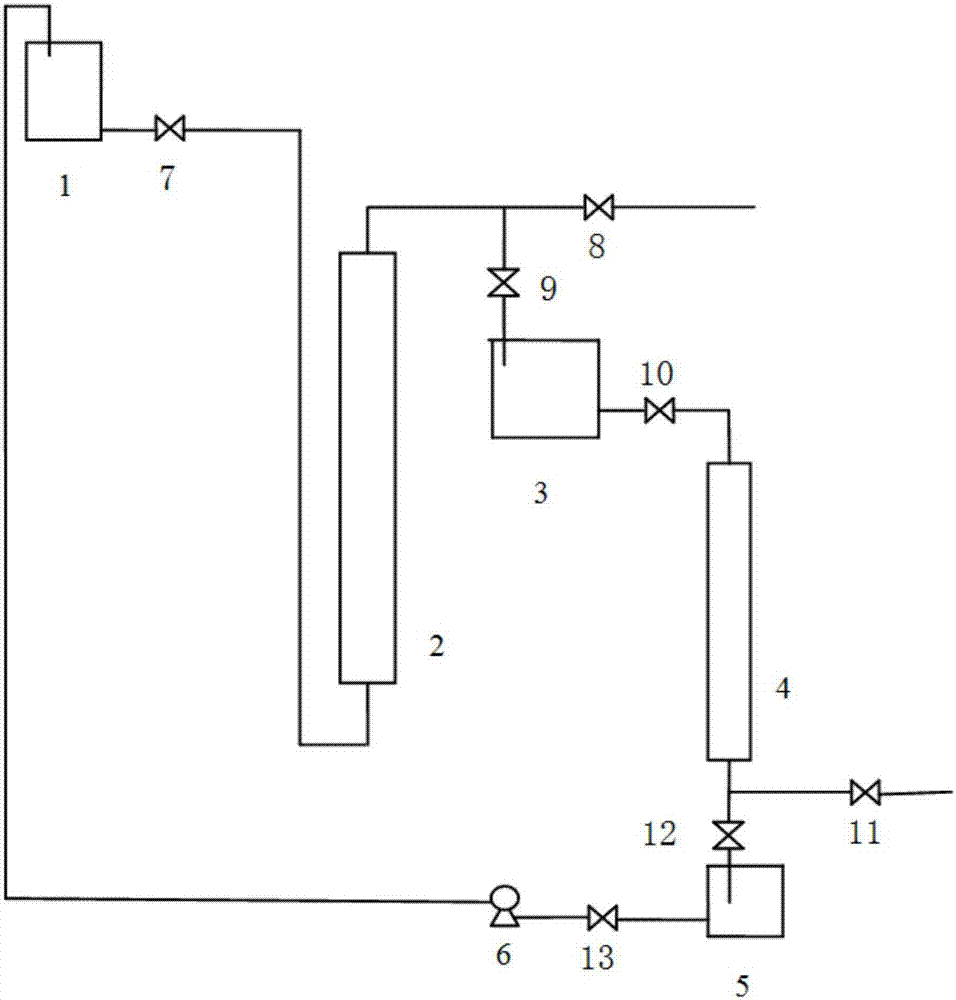

[0068] A low-carbonate sandstone uranium ore determined the concentration of the leaching agent through the preliminary indoor stirring leaching test, and carried out the column leaching test to verify the concentration of the leaching agent and find out the leaching performance of the ore and the accumulation of impurity ions.

[0069] Step 1: Sample Loading

[0070] A 1.5 kg sample, with a uranium grade of 0.050%, was loaded into a 1 L volume leaching column and compacted to a density close to that of the original core. Take 5L of mine water and place it in the leaching agent storage tank, open valve A, the mine water flows into the ore in the column from the lower end of the leaching column, close valve B, open valve C, and the mine water flows into the leach tank until the flow rate is stable, when the flow rate is stable It is 10ml / h.

[0071] 20ml of strongly basic anion exchange resin is loaded into an ion exchange column for use.

[0072] Step 2: Preparation of leach...

Embodiment 2

[0087] A sandstone uranium ore has been tested to determine the concentration of the leaching agent through the preliminary indoor stirring leaching test, and the column leaching test is carried out to verify the concentration of the leaching agent and to find out the leaching performance of the ore and the accumulation of impurity ions.

[0088] Step 1: Sample Loading

[0089]Put 3.0kg of ore sample, the uranium grade of the ore sample is 0.180%, into a leaching column with a volume of 1.5L and compact it so that its density is close to the original core density; take 4L of ore layer water and place it in a leaching agent storage tank In the process, open valve A, the mine layer water flows into the ore in the column from the lower end of the leaching column, close valve B, open valve C, and the mine layer water flows into the leach solution storage tank until the flow rate is stable, and the flow rate is 6ml / h when it is stable.

[0090] The strong basic anion exchange resin...

Embodiment 3

[0106] A sandstone uranium ore has been tested to determine the concentration of the leaching agent through the preliminary indoor stirring leaching test, and the column leaching test is carried out to verify the concentration of the leaching agent and to find out the leaching performance of the ore and the accumulation of impurity ions.

[0107] Step 1: Sample Loading

[0108] A 4.0 kg ore sample with a uranium grade of 0.250% was loaded into a leaching column with a volume of 2 L and compacted to a density close to that of the original core. Take 4L of mine layer water and place it in the leachate storage tank, open valve A, the mine layer water flows into the ore in the column from the lower end of the leaching column, close valve B, open valve C, and the mine layer water flows into the leachate storage tank until the flow rate is stable, when the flow rate is stable 15ml / h.

[0109] The weakly basic anion exchange resin of 1000ml is packed into the ion exchange column for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com