Preparation method of moisturizing and ash retaining cigarette paper

A technology of cigarette paper and calcium hydroxide, applied in the field of cigarette processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

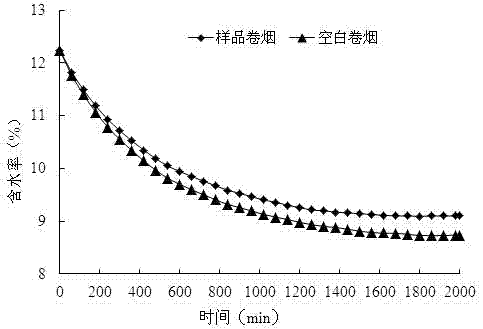

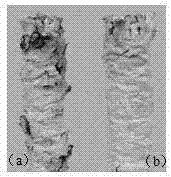

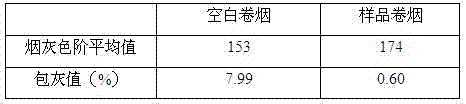

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing moist-packed ash cigarette paper, comprising the following steps:

[0025] (1) Add calcium oxide to distilled water, stir and react for 15 minutes to generate a calcium hydroxide solution with a concentration of 0.4 mol / L; under stirring conditions, add phosphoric acid dropwise to the calcium hydroxide solution at a rate of 1 mL / min, Then add sodium dodecylbenzenesulfonate, stir and age at 55±2°C for 2 hours, then cool to room temperature and centrifuge, take the solid and calcinate at 900°C for 3 hours to obtain calcium hydroxyphosphate; among them, phosphoric acid, The molar ratio of calcium hydroxide and sodium dodecylbenzenesulfonate is 1:1.67:5×10 -7 ;

[0026] (2) Calcium carbonate, calcium hydroxyphosphate obtained in step (1) and papermaking fibers are mixed and beaten according to the mass ratio of 1:7:12 to obtain slurry;

[0027] (3) The slurry obtained in step (2) is dehydrated, formed, pressed, and copied into a wet paper shape, and...

Embodiment 2

[0036] A method for preparing moist-packed ash cigarette paper, comprising the following steps:

[0037] (1) Add calcium hydroxide to distilled water, stir and react for 15 minutes to generate a calcium hydroxide solution with a concentration of 0.45 mol / L; under stirring conditions, add phosphoric acid dropwise to the calcium hydroxide solution at a rate of 0.9 mL / min , then add sodium dodecylbenzenesulfonate, stir and age at 55±2°C for 2.5 h, then cool to room temperature and centrifuge, take the solid and calcinate at 920°C for 2.5 h to obtain calcium hydroxyphosphate; among them, The molar ratio of phosphoric acid, calcium hydroxide and sodium dodecylbenzenesulfonate is 1:1.7:6×10 -7 ;

[0038] (2) Calcium carbonate, calcium hydroxyphosphate obtained in step (1) and papermaking fibers are mixed and beaten according to the mass ratio of 1:5:16 to obtain slurry;

[0039] (3) Dehydrate, shape, press, and copy the slurry obtained in step (2) into wet paper, then add sodium c...

Embodiment 3

[0042] A method for preparing moist-packed ash cigarette paper, comprising the following steps:

[0043](1) Add calcium hydroxide to distilled water, stir and react for 15 minutes to generate a calcium hydroxide solution with a concentration of 0.5 mol / L; under stirring conditions, add phosphoric acid dropwise to the calcium hydroxide solution at a rate of 0.8 mL / min , then add sodium dodecylbenzenesulfonate, stir and age at 55±2°C for 1.5 h, then cool to room temperature and centrifuge, take the solid and calcinate at 950°C for 2 h to obtain calcium hydroxyphosphate; among them, The molar ratio of phosphoric acid, calcium hydroxide and sodium dodecylbenzenesulfonate is 1:1.77:6.5×10 -7 ;

[0044] (2) Calcium carbonate, calcium hydroxyphosphate obtained in step (1) and papermaking fibers are mixed and beaten according to the mass ratio of 1:3:14 to obtain slurry;

[0045] (3) Dehydrate, shape, press, and copy the slurry obtained in step (2) into wet paper, then add sodium ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com