Ultraviolet light curing mask plate and manufacturing method and curing method therefor

A technology of mask plate and ultraviolet light, which is applied in the direction of optics, nonlinear optics, patterned surface photoplate making process, etc., can solve the problems of poor curing of frame glue, puncture, and affecting the curing of frame glue, so as to avoid the risk of puncture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

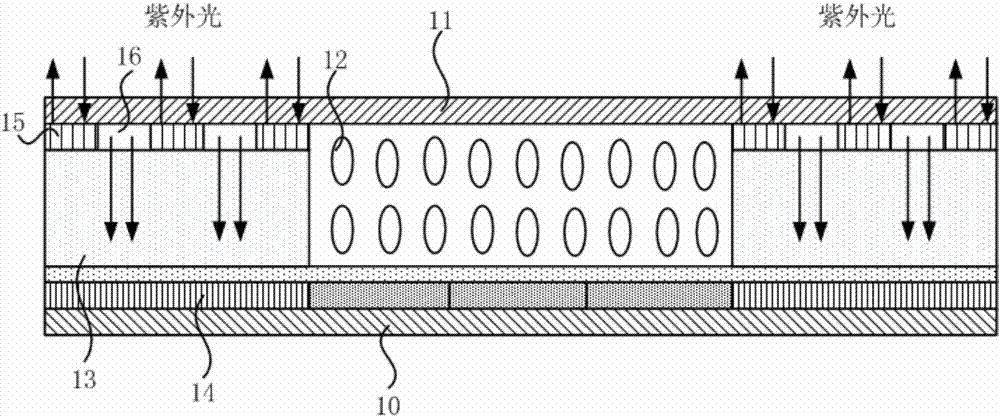

[0021] The specific implementation of the ultraviolet curing mask provided by the present invention, its manufacturing method and curing method will be described in detail below with reference to the accompanying drawings.

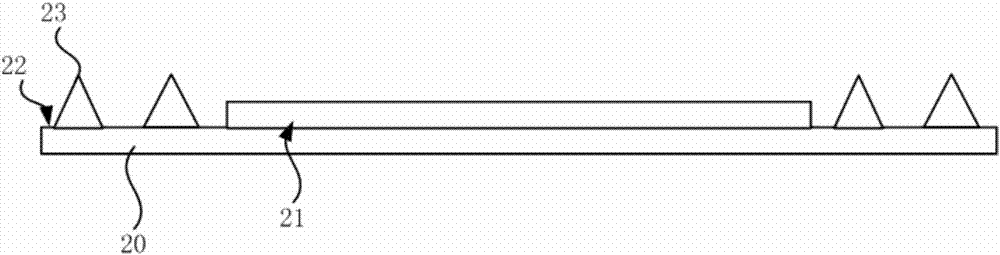

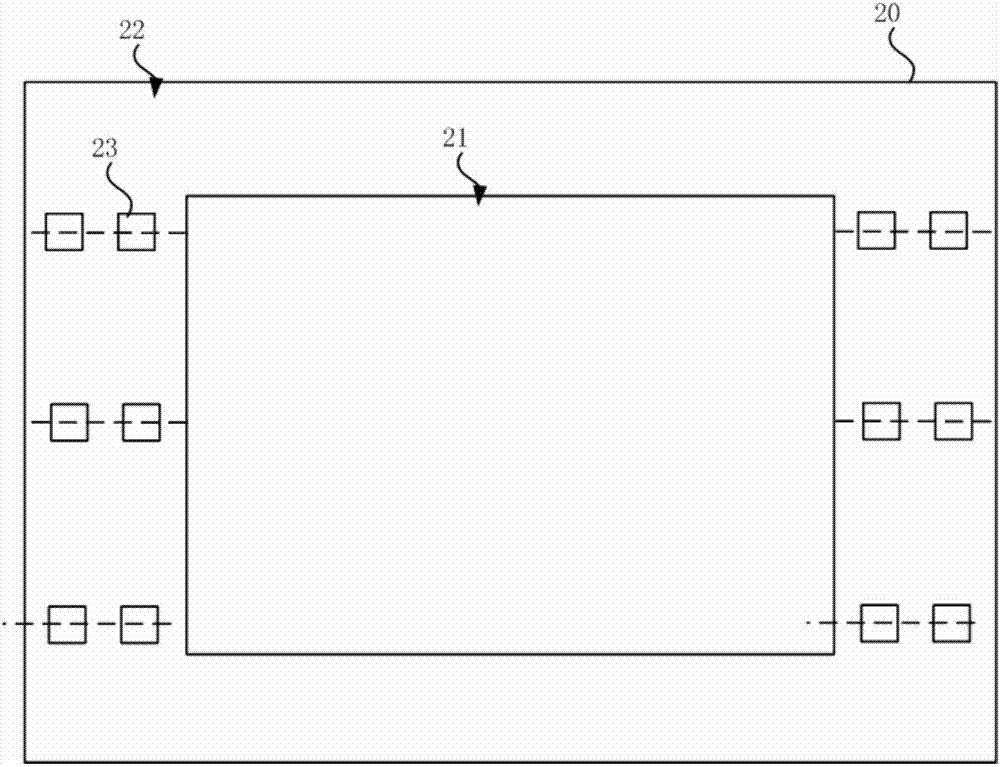

[0022] figure 2 It is a structural schematic diagram of an embodiment of the ultraviolet curing mask plate of the present invention. see figure 2 , the UV curing mask of the present invention includes a mask substrate 20 . The mask substrate 20 is made of a transparent material, such as glass. A blocking region 21 and a light-transmitting region 22 are disposed on the mask substrate 20 . The barrier area 21 corresponds to the liquid crystal area of the liquid crystal display panel. The light-transmitting area 22 corresponds to the area where the sealant of the outer frame of the liquid crystal display panel is located, and the light-transmitting area 22 allows ultraviolet light to pass through.

[0023] At least one optical path changing device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com