Sildenafil oral fast dissolving film and preparation method thereof

An oral instant film, sildenafil technology, which is applied in the directions of non-active medical preparations, pharmaceutical formulations, inorganic non-active ingredients, etc., can solve problems such as drugs that are not suitable for large doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

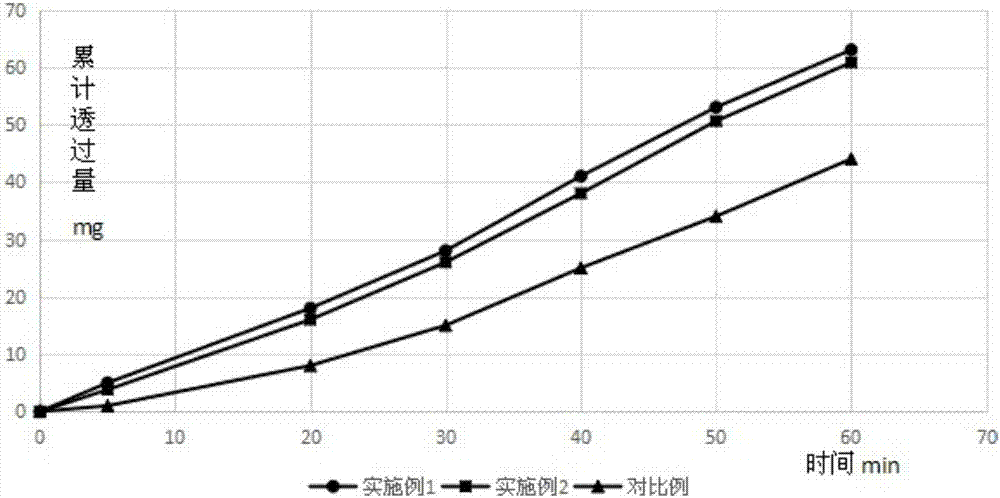

[0035] Embodiment 1 prepares sildenafil oral cavity instant film

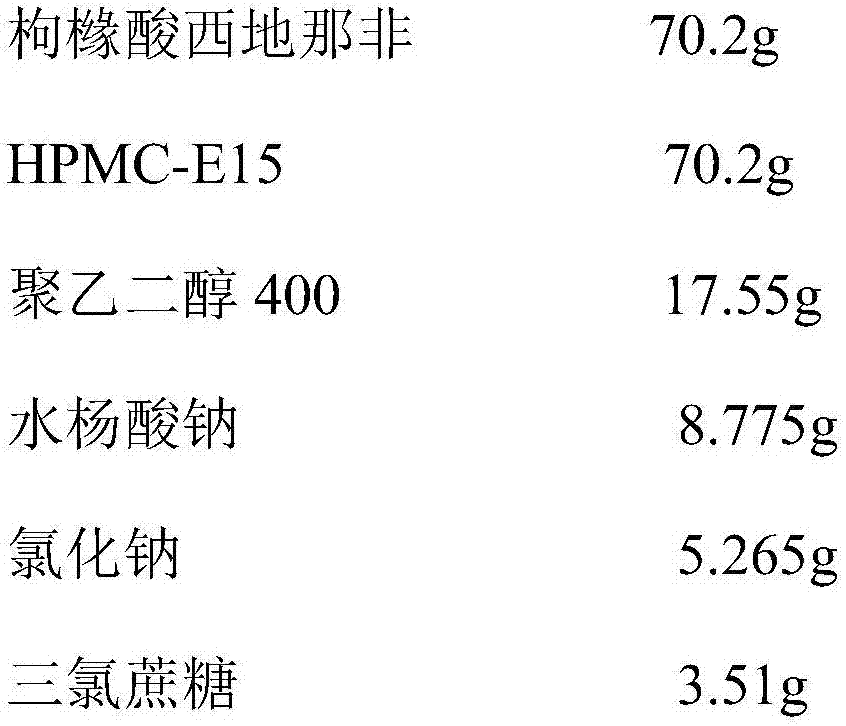

[0036] A total of 1,000 tablets, with a specification of 50 mg (calculated as sildenafil, containing 70.2 mg of sildenafil citrate), and its raw material composition is as follows:

[0037]

[0038] Disperse sildenafil citrate and sodium chloride in 280.8g of water to obtain a uniform suspension solution, then add HPMC-E15, polyethylene glycol 400, sodium salicylate, and sucralose, stir evenly, defoam, and coat Film, dry at 40-80°C, cut and pack.

[0039] The film has a good appearance, milky white, smooth to the touch, a thickness of 80±5μm, a tensile strength of 9.2±1Mpa, a slightly sweet taste, and a melting time of 25s.

Embodiment 2

[0040] Embodiment 2 prepares sildenafil oral cavity instant film

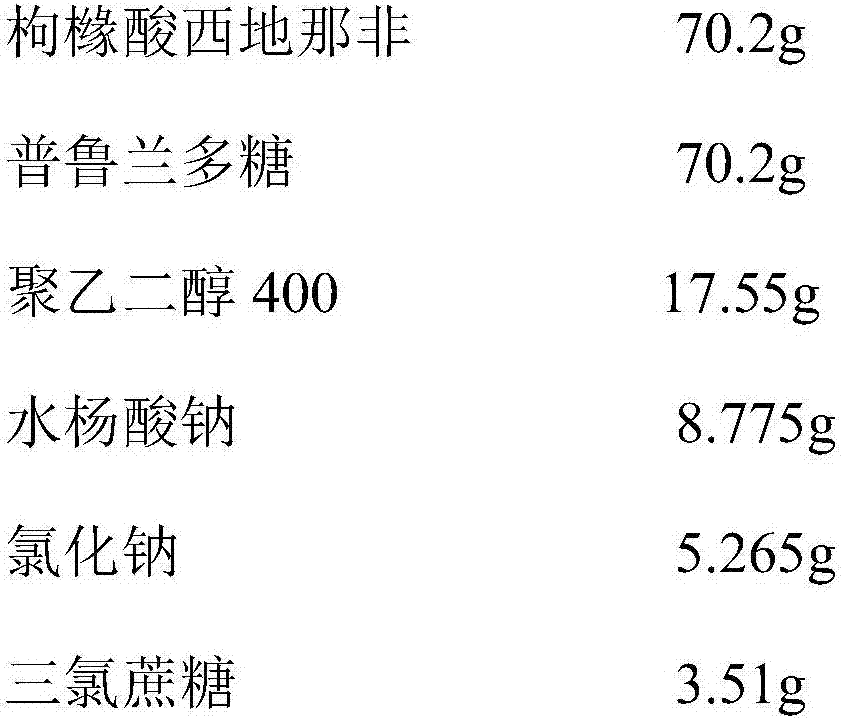

[0041] A total of 1,000 tablets, with a specification of 50 mg (calculated as sildenafil, containing 70.2 mg of sildenafil citrate), and its raw material composition is as follows:

[0042]

[0043] Disperse sildenafil citrate and sodium chloride in 280.8g of water to obtain a uniform suspension solution, then add pullulan, polyethylene glycol 400, sodium salicylate, and sucralose, stir evenly, and defoam. Coated film, dried at 40-80°C, cut and packaged.

[0044] The film has a good appearance, milky white, smooth to the touch, a thickness of 80±5μm, a tensile strength of 8.5±1Mpa, a slightly sweet taste, and a melting time of 28s.

Embodiment 3

[0045] Embodiment 3 prepares sildenafil oral cavity instant film

[0046] A total of 1,000 tablets, with a specification of 50 mg (calculated as sildenafil, containing 70.2 mg of sildenafil citrate), and its raw material composition is as follows:

[0047]

[0048] Disperse sildenafil citrate and sodium chloride in 280.8g of water to obtain a uniform suspension solution, then add HPMC-E15, polyethylene glycol 400, sodium salicylate, and sucralose, stir evenly, defoam, and coat Film, dry at 40-80°C, cut and pack.

[0049] The film has a good appearance, milky white, smooth to the touch, a thickness of 80±5μm, a tensile strength of 10.7±1Mpa, a slightly bitter taste, and a melting time of 35s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com