Machining process of glass for automobile lampshade

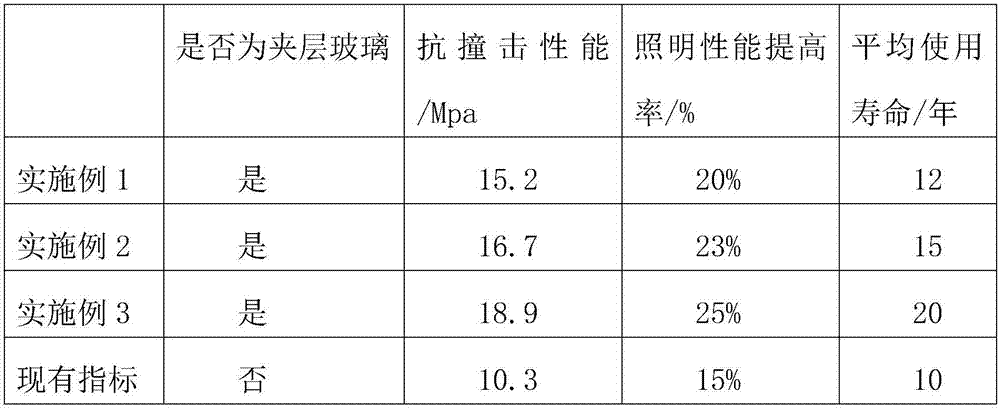

A processing technology and glass technology, applied in glass manufacturing equipment, glass cutting devices, glass/slag layered products, etc., can solve the problem of reduced light transmission performance of glass, low impact resistance of thin glass, impact performance and other properties that are not fundamental. to improve the lighting performance, improve the transparency, and strengthen the impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A process for processing glass for automobile lampshades, the steps including:

[0025] (1) Surface glass strengthening

[0026] Pre-treat the white glass sheet before strengthening, soak the white glass sheet in hot water at 65°C for 20 minutes, put the white glass sheet in a high-purity potassium nitrate solution and the matched catalyst, and heat it to 400°C for 40 minutes. After strengthening, the temperature is lowered to 50℃ for heat preservation and cooling, and then naturally cooled, the chemically strengthened glass can be cleaned and dried. The purity of the high-purity potassium nitrate solution is chemically pure, with a purity of 99.6%. The catalyst includes 30 parts of trioxide Dialuminium, 30 parts of potassium permanganate, 20 parts of potassium fluoride and 20 parts of potassium silicate;

[0027] (2) Processing of laminated convex glass

[0028] Select the pre-produced convex glass for finishing, and process the laminated convex glass into a shape with a thic...

Embodiment 2

[0036] A processing technology of glass for automobile lampshades, the steps including:

[0037] (1) Surface glass strengthening

[0038] Before strengthening, the white glass flakes are pretreated. The white flakes are soaked in hot water at 65℃ for 20 minutes, and the white flakes are mixed with high-purity potassium nitrate solution and the matched catalyst and heated to 420℃ for 35 minutes. After strengthening, the temperature is lowered to 50℃ for heat preservation and cooling, and then naturally cooled, the chemically strengthened glass is cleaned and dried. The purity of the high-purity potassium nitrate solution is chemically pure, with a purity of 99.6%. The catalyst includes 30 parts of trioxide Dialuminium, 30 parts of potassium permanganate, 20 parts of potassium fluoride and 20 parts of potassium silicate;

[0039] (2) Processing of laminated convex glass

[0040] Select the pre-produced convex glass for finishing, and process the laminated convex glass into a shape with...

Embodiment 3

[0048] A processing technology of glass for automobile lampshades, the steps including:

[0049] (1) Surface glass strengthening

[0050] Before strengthening, the white glass flakes are pretreated. The white flakes are soaked in hot water at 65℃ for 20 minutes. The white flakes are mixed with high-purity potassium nitrate solution and the matched catalyst and heated to 450℃ for 30 minutes. After strengthening, the temperature is lowered to 50℃ for heat preservation and cooling, and then naturally cooled, the chemically strengthened glass can be cleaned and dried. The purity of the high-purity potassium nitrate solution is chemically pure, with a purity of 99.6%. The catalyst includes 30 parts of trioxide Dialuminium, 30 parts of potassium permanganate, 20 parts of potassium fluoride and 20 parts of potassium silicate;

[0051] (2) Processing of laminated convex glass

[0052] Select the pre-produced convex glass for finishing, and process the laminated convex glass into a shape with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com