Production process for s-trioxane and extraction reaction tower

A paraformaldehyde and production process technology, applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve the problems of large equipment investment, large steam consumption, reaction and separation, etc., to reduce steam energy consumption and improve conversion rate , the effect of reducing the difficulty of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

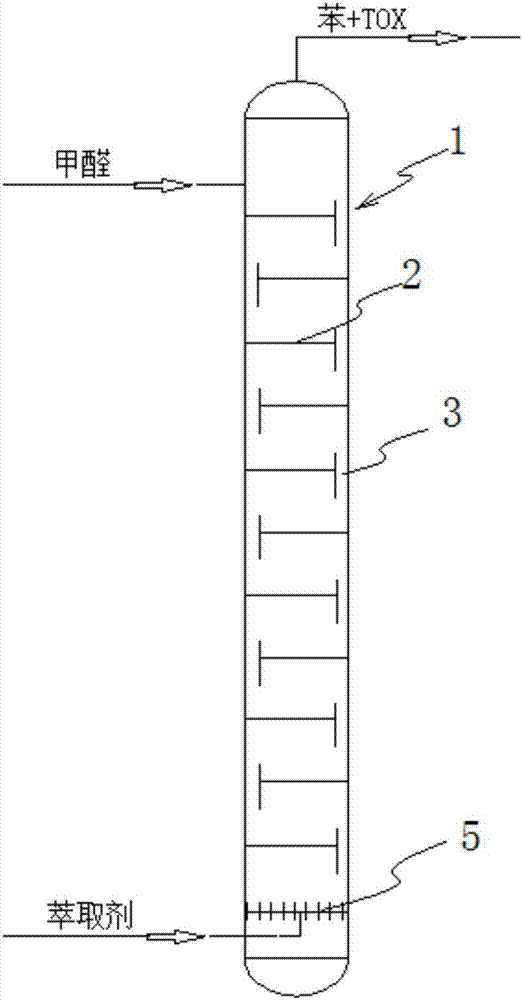

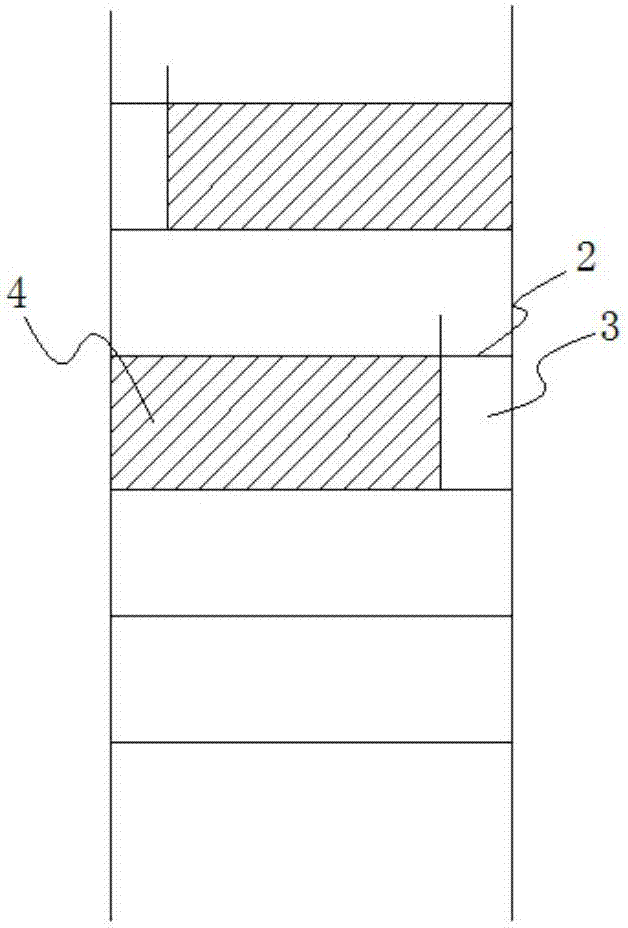

[0023] Such as Figure 1~2 As shown, the extraction reaction tower of the present invention includes a tower body, and multi-stage extraction reaction units are arranged from bottom to top in the tower, and adjacent ones are separated by trays, and a plurality of through holes are provided on the trays, and each layer of trays A downcomer is provided on the top. The space between adjacent trays is used as the extraction reaction section of the extraction reaction unit, and the solid acid packing layer is fixedly installed in the upper part of the section. The bottom of the tower is provided with a distributor and is connected to the delivery pipe of the extractant benzene, the top of the tower is provided with a reactant extraction port and is connected with the extraction pipe, and the upper part of the tower is provided with a formaldehyde delivery port for the formaldehyde solution to enter. Benzene enters from the bottom of the tower and is distributed into the tower thro...

Embodiment 2

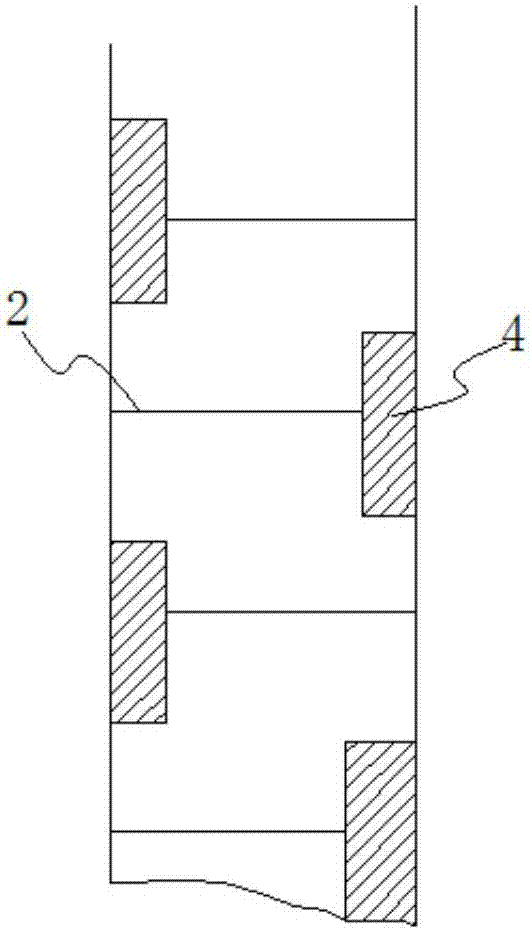

[0026] Such as image 3 In this embodiment, the solid acid catalyst is directly placed in the downcomer, and when the formaldehyde solution flows through the downcomer from the upper extraction reaction unit, it contacts with the solid acid catalyst to undergo a polymerization reaction.

Embodiment 3

[0028] In this embodiment, the solid acid catalyst is placed in the external reactor by installing an external suspension outside the tower, and the formaldehyde solution descending from the upper layer is sent into the external reactor through a circulation pump and pipeline for polymerization reaction, and the product of the polymerization reaction is sent to the external reactor. After returning, it enters the extraction reaction unit of the lower layer, the organic phase rises, and the water phase descends. In this embodiment, the residence time of the formaldehyde solution in the catalyst can be ensured to improve the reaction conversion rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com