Anti-corrosion self-restoration paint

A self-repairing and coating technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficult scale production of nano-containers, and achieve a simple and easy-to-control preparation method, strong anti-corrosion performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

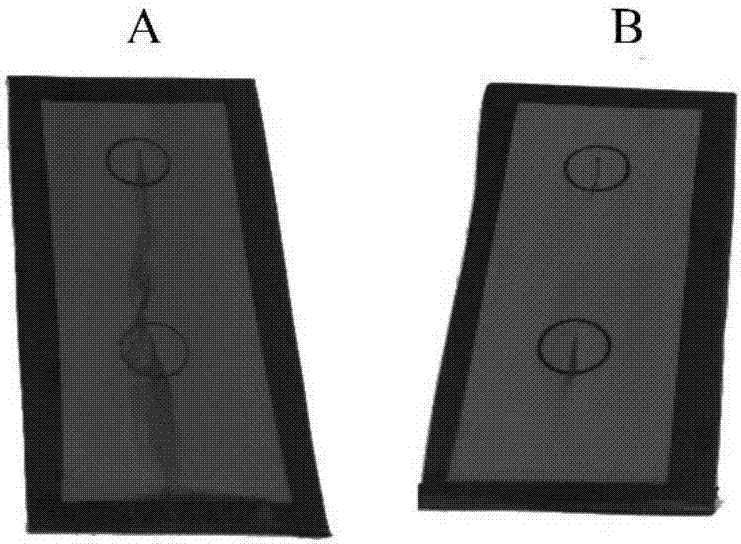

[0040] Disperse the synthesized polydivinylbenzene microspheres with a particle size of 1 μm and carboxyl groups (the pH response range is 6-10, and the loaded corrosion inhibitor can be released faster when the pH value increases) to 500 g / L The corrosion inhibitor benzotriazole ethanol solution was mixed and stirred at 70°C for 10 hours, washed with deionized water and dried to obtain the self-repairing component. Add epoxy resin to 5% of the total amount of paint, stir at 500rpm for 10 minutes until the mixture is uniform, then add curing agent polyamide to the mixture, stir it evenly, and then spray it on the iron plate. The surface of the iron plate after spraying is smooth and smooth as figure 1 as shown, figure 2 After 130h salt spray test (A) commercially available epoxy zinc-rich primer (B) self-made intelligent anti-corrosion self-repairing coating rust comparison chart at scratches, it can be seen that the self-repairing epoxy primer can significantly improve the ...

Embodiment 2

[0042] The synthetic polydivinylbenzene microspheres with a particle size of 1 μm (pH response range of 6-9, and can release the loaded corrosion inhibitor faster when the pH value rises) were dispersed to 1000 g / L The corrosion inhibitor benzotriazole ethanol solution was mixed and stirred at 70°C for 24 hours, washed with deionized water and dried to obtain the self-repairing component. Add epoxy resin to 10% of the total mass of the paint, stir at 700rpm for 30 minutes until evenly mixed, then add curing agent polyamide to the mixed solution, stir evenly, and then apply it to the iron plate. The surface of the iron plate after painting is smooth and smooth as image 3 as shown, Figure 4 After 180h salt spray test (A) commercially available epoxy zinc-rich primer (B) self-made intelligent anti-corrosion self-repairing coating rust comparison chart at scratches, it can be seen that the self-repairing epoxy primer can significantly improve the anti-corrosion performance of t...

Embodiment 3

[0044]The synthesized polystyrene-based microspheres with a particle size of 0.1 μm (pH response range of 6-9, and can release the loaded corrosion inhibitor faster when the pH value rises) were dispersed to 500 g / L of corrosion inhibitor agent benzotriazole ethanol solution, mixed and stirred at 50°C for 10 h, washed with deionized water and dried to obtain the self-repairing component. Add epoxy resin according to the mass ratio of 5% of the total amount of paint, stir at 500rpm for 10 minutes until mixed evenly, then add curing agent polyamide into the mixed solution, stir evenly, and then apply it to the aluminum plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com