Solvent type rubber asphalt waterproof coating and preparation method thereof

A technology for waterproof coating and rubber asphalt, applied in the direction of asphalt coating, coating, etc., can solve the problems of reducing the elongation of modified asphalt, swelling SBS for a long time, affecting the effect of modified asphalt, etc., achieving complete modification, uniform dispersion, Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

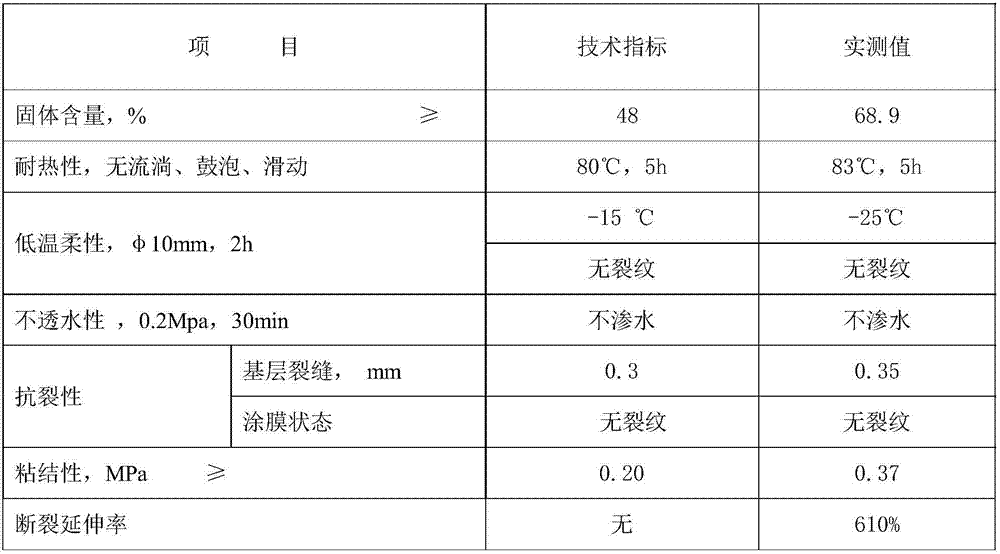

Embodiment 1

[0027] Prepare each raw material by formula: in parts by weight, 45 parts of No. 70 road petroleum asphalt, 31 parts of xylene, 10 parts of SBS4402 (star structure), 4 parts of amorphous α-olefin copolymers (purchased from Liaohua Qida Co., Ltd. ), 10 parts of light calcium; add asphalt and xylene to the reaction vessel, heat up to 86°C to form the first product; add SBS4402 to the reaction vessel, control the temperature at about 86°C, 2000 rpm high-speed melting shear 55 minutes until SBS4402 is completely dissolved to form the second product; add amorphous α-olefin copolymer to the reaction vessel, control the temperature at about 85°C, and stir at 2000 rpm for 0.5 hours to form the third product; add to the reaction vessel Light calcium, the temperature is controlled at about 75°C, the fourth product is formed after high-speed stirring at the above-mentioned speed, and the solvent-based rubber asphalt waterproof coating is obtained after the fourth product is cooled to 50°C...

Embodiment 2

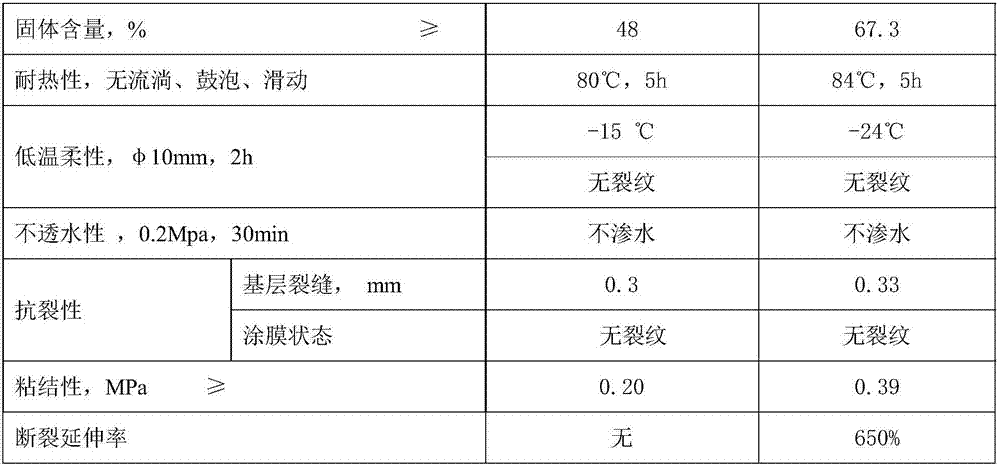

[0029] Prepare each raw material by formula: in parts by weight, No. 90 road petroleum asphalt 43 parts, D70 is 33 parts of solvent naphtha, SBS4303 (star structure) 8 parts, amorphous α olefin copolymer 4 parts (purchased in Liaohua Qi up to the company), 12 parts of heavy calcium;

[0030] Add asphalt and D70 to the reaction vessel, heat up to 90°C to form the first product; add SBS4303 to the reaction vessel, control the temperature at about 90°C, and melt and shear at 2000 rpm for 60 minutes until the SBS4303 is completely dissolved and formed The second product; add amorphous α-olefin copolymer to the reaction vessel, control the temperature at about 90°C, stir at a high speed of 2000 rpm for 0.5h to form the third product; add light calcium to the reaction vessel, control the temperature at 78 ℃, 2000 rpm high-speed stirring to form the fourth product, and the fourth product is cooled to 50 ℃ to obtain the solvent-based rubber asphalt waterproof coating.

Embodiment 3

[0032] Prepare each raw material by formula: in parts by weight, No. 90 road petroleum asphalt 45 parts, D80 is 34 parts of solvent naphtha, SBS4402-1 (star structure) 7 parts, 3 parts of amorphous α olefin copolymers (purchase in Liao Huaqida company), 11 parts of heavy calcium;

[0033] Add asphalt and D90 to the reaction vessel, heat up to 95°C to form the first product; add SBS4402-1 to the reaction vessel, control the temperature at about 95°C, melt and shear at 2000 rpm for 60 minutes to SBS4402-1 After complete dissolution, the second product is formed; add amorphous α-olefin copolymer to the reaction vessel, control the temperature at about 95°C, and stir at 2000 rpm for 0.5 hours to form the third product; add heavy calcium to the reaction vessel, The temperature is controlled at about 80°C, and the fourth product is formed after stirring at a high speed of 2000 rpm, and the solvent-based rubber asphalt waterproof coating is obtained after the fourth product is cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com