Drilling fluid, and local crushing formation inclined well inverse well guide hole drilling process

A water-based drilling fluid and pilot hole technology, applied in directional drilling, wellbore/well components, drilling composition, etc., can solve the problems of insufficient inhibition performance, difficulty in solving wellbore, unstable wellbore, etc. Conducive to stability and storage protection, improving the ability to stabilize the well wall, preventing the effect of well wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

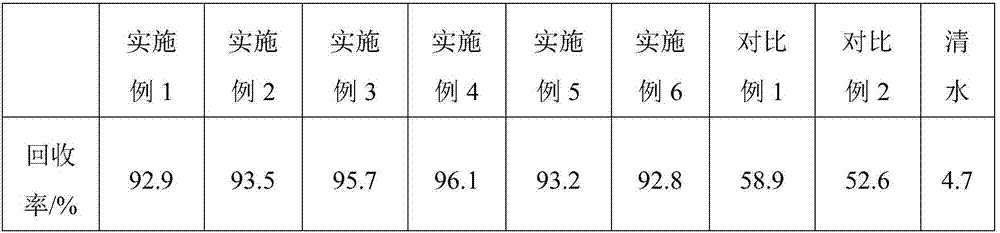

Examples

Embodiment 1

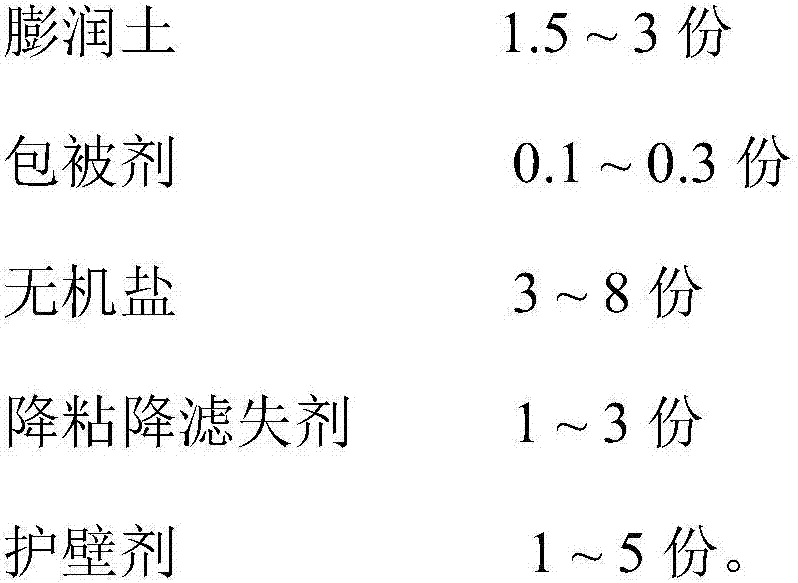

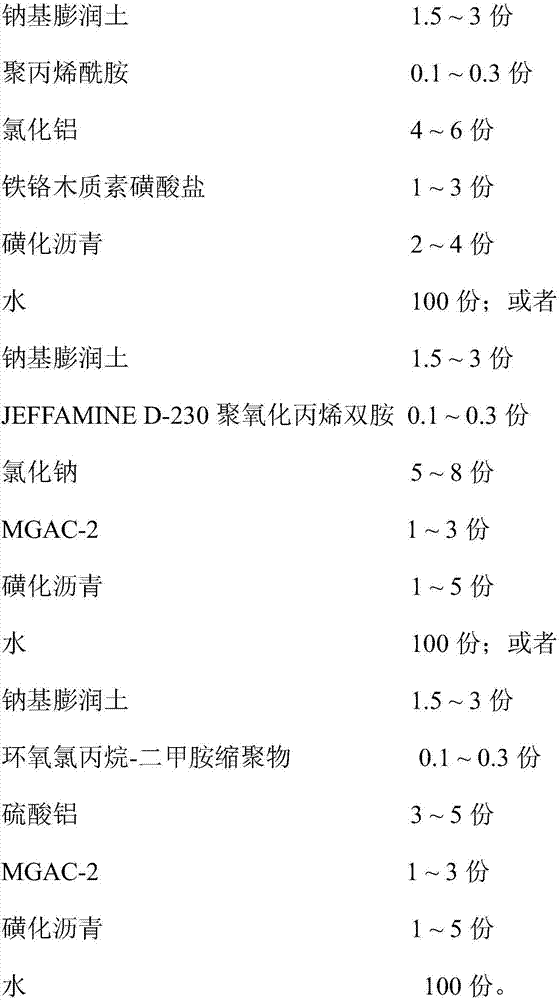

[0041] A water-based drilling fluid consisting of:

[0042] Sodium bentonite 1.5g, polyacrylamide 0.3g, aluminum chloride 4g, iron chromium lignosulfonate 1g, sulfonated pitch 2g, water 100g.

[0043] In 100g of clear water, add each component in the formula amount, stir well, make it mix completely and uniformly, obtain the described water-based drilling fluid.

Embodiment 2

[0045] A water-based drilling fluid consisting of:

[0046] Sodium bentonite 3g, polyacrylamide 0.1g, aluminum chloride 6g, iron chromium lignosulfonate 3g, sulfonated pitch 4g, water 100g.

[0047] In 50g of clear water, add the remaining components in the formula amount, stir for 2 minutes, then add 50g of water, stir well, make it completely and evenly mixed, and obtain the water-based drilling fluid.

Embodiment 3

[0049] A water-based drilling fluid consisting of:

[0050] Sodium bentonite 3g, JEFFAMINE D-230 polyoxypropylene diamine 0.1g, sodium chloride 8g, MGAC-2 1g, sulfonated pitch 1g, water 100g.

[0051] In 100g of clear water, add each component in the formula amount, stir well, make it mix completely and uniformly, obtain the described water-based drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com