Nanometer reinforced high-strength low-carbon Nb-contained steel for hot galvanization and preparation method thereof

A high-strength, hot-dip galvanizing technology, applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of soaring prices of scarce elements and resource shortages, and achieve the purpose of inhibiting the formation of pearlite and improving the forming process. performance and formability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

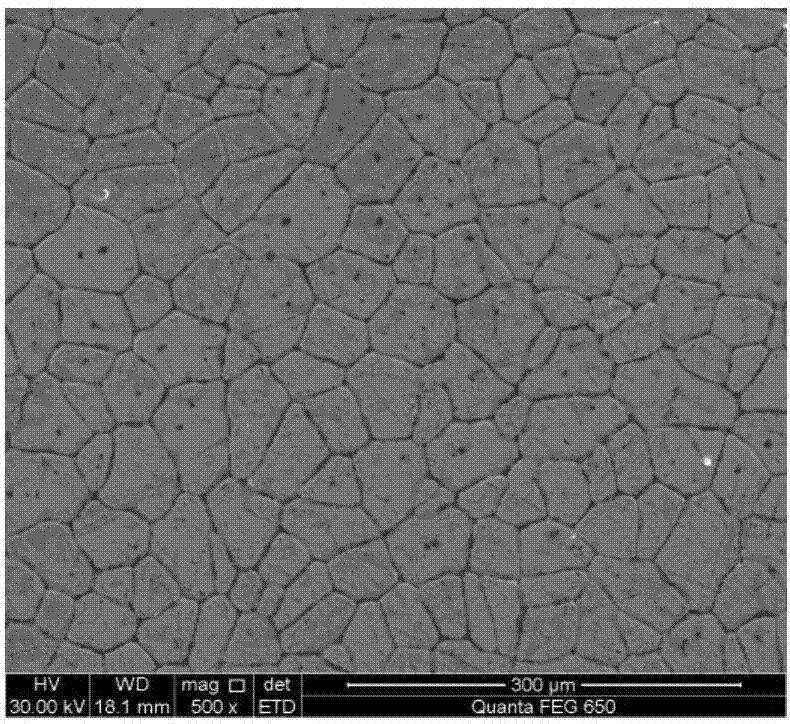

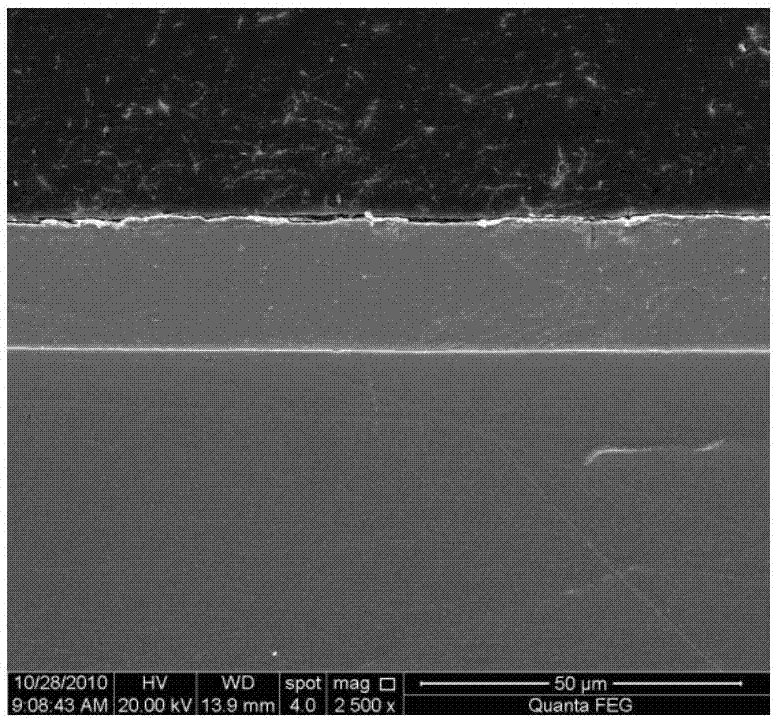

[0065] The chemical composition of the nano-strengthened high-strength low-carbon Nb-containing steel in this example is shown in Table 1.

[0066] Table 1 Chemical composition (wt%) of nano-strengthened high-strength low-carbon Nb-containing steel

[0067]

[0068] The preparation process of nano-strengthened high-strength low-carbon Nb-containing steel in this embodiment is as follows Figure 5 As shown, the present embodiment smelts 250Kg experimental steel in a vacuum induction furnace, and the preparation process of nano-strength high-strength low-carbon Nb-containing steel is: vacuum smelting, casting, slab heating, hot rolling, cooling, pickling, cold Rolling, continuous annealing, the specific steps are:

[0069] Step 1. Vacuum smelting

[0070] In this embodiment, a 250Kg experimental vacuum induction furnace is used for smelting to ensure the stability of the chemical composition and tissue performance of the material;

[0071] Step 2. Casting

[0072] In this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com