Water-repellent, oil-repellent, non-ironing, washable and shrink-resistant knitwear and preparation method thereof

A water and oil repellent, anti-shrinkage technology, applied in the field of textiles and clothing, can solve the problems of non-ironing and washable ultra-low shrinkage knitted garments, etc., to improve the initial effect and washability, small size fluctuations, and improve non-ironing The Effect of Washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing a water-repellent, oil-repellent, non-iron, washable and shrink-proof knitted garment, which includes the following steps:

[0055] 1) Fabric treatment: Wash the dyed 40S×2 pure cotton single-bead knitted fabric, the detergent used is RUCOGEN AIL-C (produced by Rudolf Chemical), and the concentration of the detergent is 2g / L , The washing temperature is 60℃, and the washing time is 20min. Dry the fabric after washing.

[0056] Use a setting machine to pass the fabric through the treatment liquid, which, based on the total volume, includes the anti-needle soft oil RUCO-LUB (produced by Rudolph Chemical) 20g / L, penetrant 1g / L, and acetic acid 0.1g / L , Control the pH of the cloth surface to 6.7, and the bursting force to 80PSI.

[0057] 2) Garment production: the above knitted fabrics are made into garments.

[0058] 3) Apply finishing liquid to the garment: On the automatic spraying machine, a certain amount of finishing liquid pre...

Embodiment 2

[0066] This embodiment provides a method for preparing a water-repellent, oil-repellent, non-iron, washable and shrink-proof knitted garment, which includes the following steps:

[0067] The fabric in this embodiment is 40S / 1 pure cotton wool cloth after dyeing.

[0068] 1) Fabric treatment: Same as Example 1.

[0069] 2) Garment production: the above fabrics are made into garments.

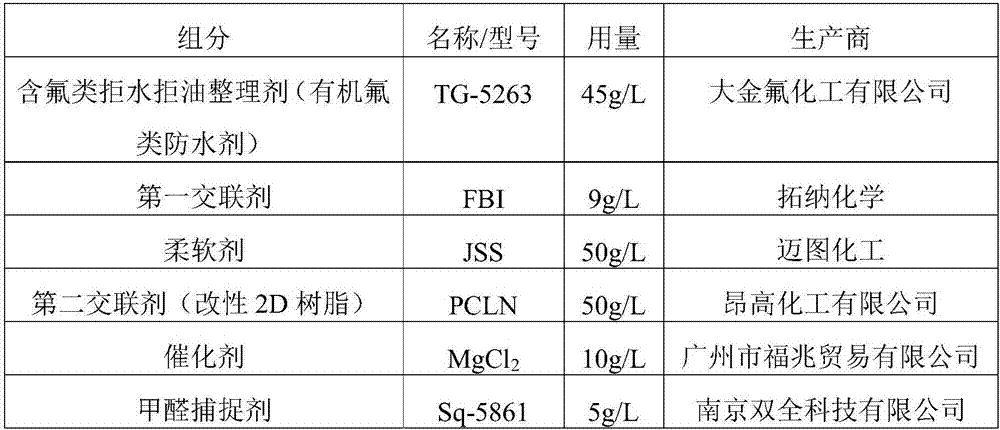

[0070] 3) Apply finishing liquid to the garment: the raw material composition of the finishing liquid is shown in Table 2, and the other operations are the same as in Example 1.

[0071] 4) Pre-bake: same as Example 1.

[0072] Table 2

[0073] Component

name

Dosage

supplier

Fluorine-containing water and oil repellent finishing agent

TG-5263

50g / L

Daikin Fluorochemical Co., Ltd.

First crosslinker

FBI

10g / L

Tona Chemical

Softener

JSS

30g / L

Momentive Chemical

Second crosslinking agent (modified 2D resin)

PCLN

60g / L

Argo Chemical Co., Ltd.

catalyst

MgCl 2

12g / L

Guangzhou Fu Zhao ...

Embodiment 3

[0078] This embodiment provides a method for preparing a water-repellent, oil-repellent, non-iron, washable and shrink-proof knitted garment, which includes the following steps:

[0079] table 3

[0080]

[0081]

[0082] The fabric in this embodiment is 20S / 1 pure cotton plain weave after dyeing.

[0083] 1) Fabric treatment: Same as Example 1.

[0084] 2) Garment production: the above fabrics are made into garments.

[0085] 3) Applying finishing liquid to the garment: the composition of the finishing liquid in this example is shown in Table 3, and the rest of the operation is the same as in Example 1.

[0086] 4) Pre-bake: same as Example 1.

[0087] 5) Positioning ironing: same as Example 1.

[0088] 6) Flat-laying baking: the baking temperature in this embodiment is 130°C, the baking time is 5min, and the rest of the operation is the same as in Example 1. The water-repellent, oil-repellent, non-iron, washable, and ultra-low shrinkage pure cotton plain weave cloth Sleeve shirt.

[0089...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com