A kind of modified polypropylene material for low-voc low-gloss low-shrinkage automotive interior and preparation method thereof

A polypropylene material and automotive interior technology, applied in the field of automotive interior parts, can solve the problems of large differences in glossiness of plastic parts, increase of VOC content in the car, frequent maintenance of molds, etc., to create a low-gloss environment, Excellent mechanical properties and processing properties, the effect of reducing visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

[0047] The index steps of each embodiment are as follows:

[0048] Put PP resin, POE resin, talc, matting agent, adsorbent, and other additives (including main antioxidant, auxiliary antioxidant, light stabilizer, lubricant, carbon black) in a high-speed mixer, at 1400± Stir for 4±1min at a speed of 50r / min, and mix evenly; then add the obtained premix into a co-rotating twin-screw extruder, melt, knead, extrude and granulate to obtain low-VOC, low-gloss, and low-shrinkage automotive interior trim With polypropylene material. The extrusion temperature is 200±10℃, the extruder main engine speed is 500±10r / min, and the feeding is 800kg / h.

[0049] The formula of each component in Examples 1-15 is shown in Table 1-3, and the performance index is shown in Table 5.

[0050] The formula of each component of Comparative Example 1-5 is shown in Table 4, the preparation method is the same as that of Example 1-15, and the performance index is shown in Table 4.

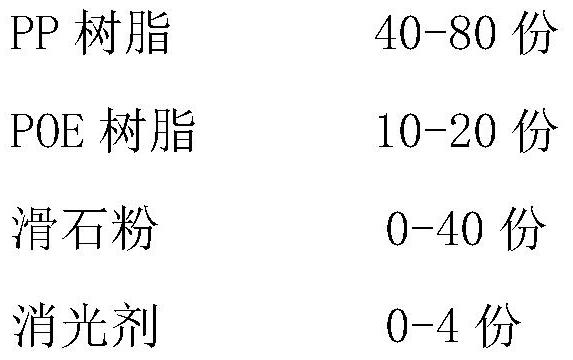

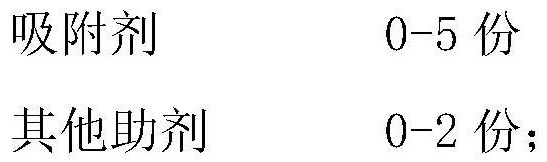

[0051] Table 1 The di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com