A kind of making method of flute membrane for bamboo flute

A production method and flute membrane technology, which are applied in the field of musical instrument manufacturing, can solve the problems of easy rupture of flute membranes and water supply, etc., and achieve the effects of being difficult to rupture, easy to mass produce, and high structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of manufacture method of flute membrane for bamboo flute, comprises the following steps:

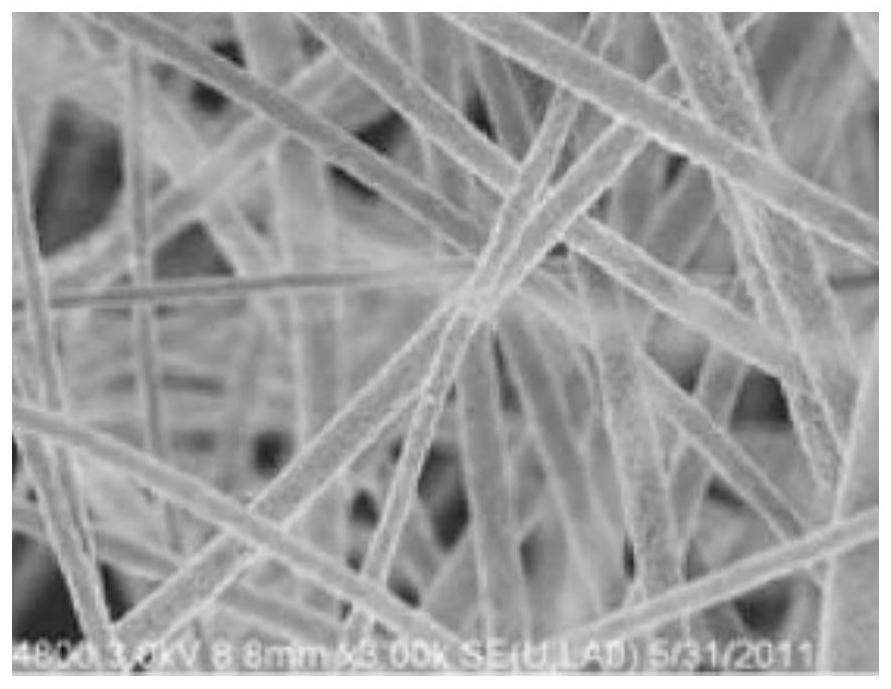

[0031] Step 1) prepare micro-nano multi-level structure polysulfone fiber membrane, the molecular weight of described polysulfone is 50000, polysulfone is dissolved in DMF / acetone mixed solvent, stirring and dissolving, add bamboo juice, the mass ratio of bamboo juice and polysulfone is 1:5, to obtain a spinning solution with a mass fraction of polysulfone of 10%, and electrospinning to prepare a polysulfone fiber membrane with a micro-nano hierarchical structure;

[0032] The bamboo juice is the juice obtained by squeezing the inner wall of the bamboo, which is centrifuged to remove insoluble impurities, and is kept overnight for later use;

[0033] Electrospinning uses a single nozzle electrospinning system with a voltage of 5kv, a flow rate of 1mL / h, a spinning distance of 8cm, a cylinder traverse distance of 5cm, a traverse speed of 10cm / min, and a spinning speed of 2m / ...

Embodiment 2

[0037] A kind of manufacture method of flute membrane for bamboo flute, comprises the following steps:

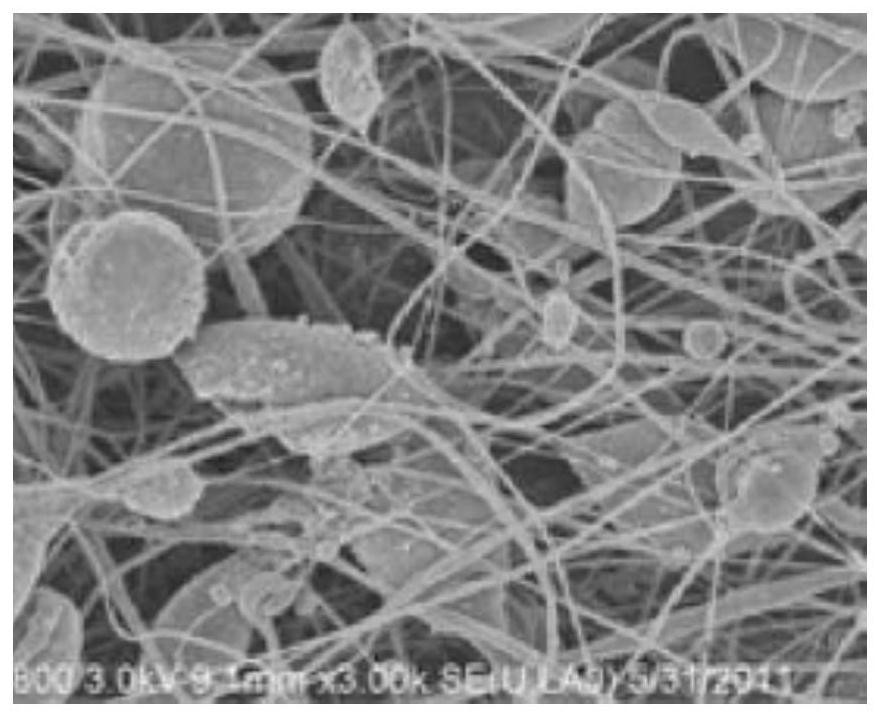

[0038] Step 1) prepare micro-nano multi-level structure polysulfone fiber membrane, the molecular weight of described polysulfone is 80000, polysulfone is dissolved in DMF / acetone mixed solvent, stirring and dissolving, add bamboo juice, the mass ratio of bamboo juice and polysulfone is 1:8, to obtain a spinning solution with a mass fraction of polysulfone of 10%, and electrospinning to prepare a polysulfone fiber membrane with a micro-nano multi-level structure;

[0039] The bamboo juice is the juice obtained by squeezing the inner wall of the bamboo, which is centrifuged to remove insoluble impurities, and is kept overnight for later use;

[0040] Electrospinning uses a single nozzle electrospinning system with a voltage of 7kv, a flow rate of 1mL / h, a spinning distance of 10cm, a cylinder traverse distance of 8cm, a traverse speed of 14cm / min, and a spinning speed of 4m / ...

Embodiment 3

[0044] A kind of manufacture method of flute membrane for bamboo flute, comprises the following steps:

[0045]Step 1) Prepare a polysulfone fiber membrane with a micro-nano hierarchical structure, the molecular weight of the polysulfone is 150000, dissolve the polysulfone in a DMF / acetone mixed solvent, stir and dissolve, add reed juice, bamboo juice or reed juice and polysulfone The mass ratio is 1:10 to obtain a spinning solution with a polysulfone mass fraction of 15%, and electrospinning to prepare a polysulfone fiber membrane with a micro-nano hierarchical structure;

[0046] The reed juice is the juice obtained by squeezing the inner wall of the reed stalk, centrifuged to remove insoluble impurities, and kept overnight for later use;

[0047] Electrospinning uses a single nozzle electrospinning system with a voltage of 12kv, a flow rate of 1.5mL / h, a spinning distance of 10cm, a cylinder traverse distance of 8cm, a traverse speed of 14cm / min, and a spinning speed of 4m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com