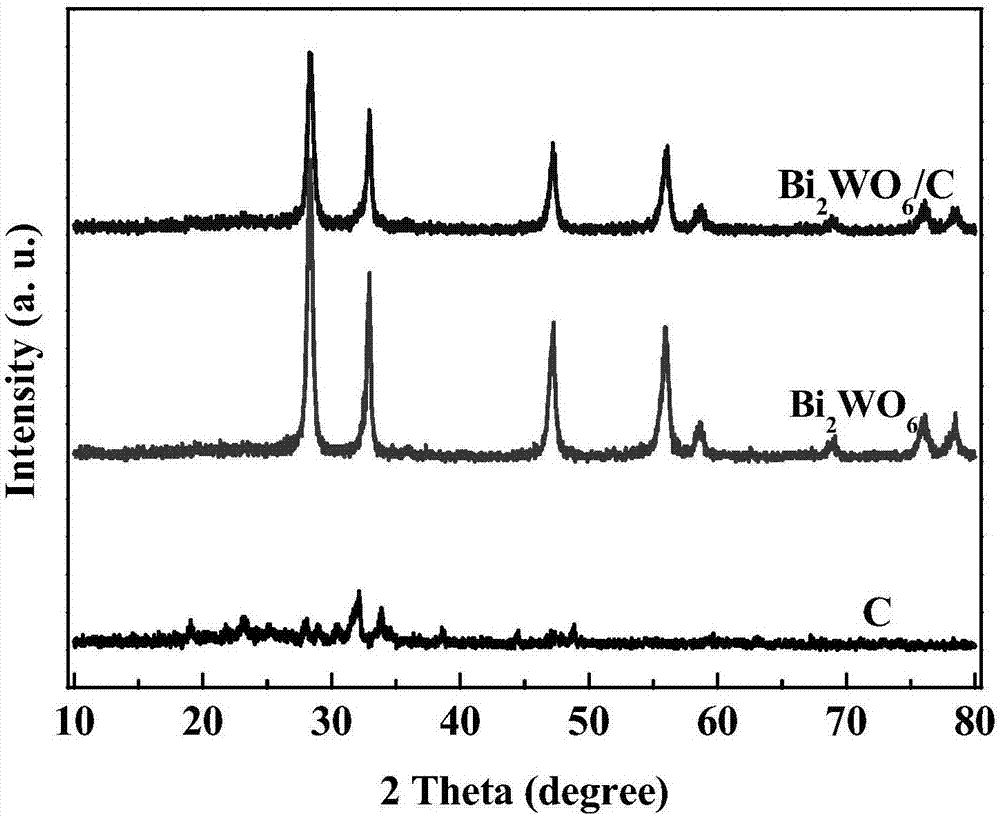

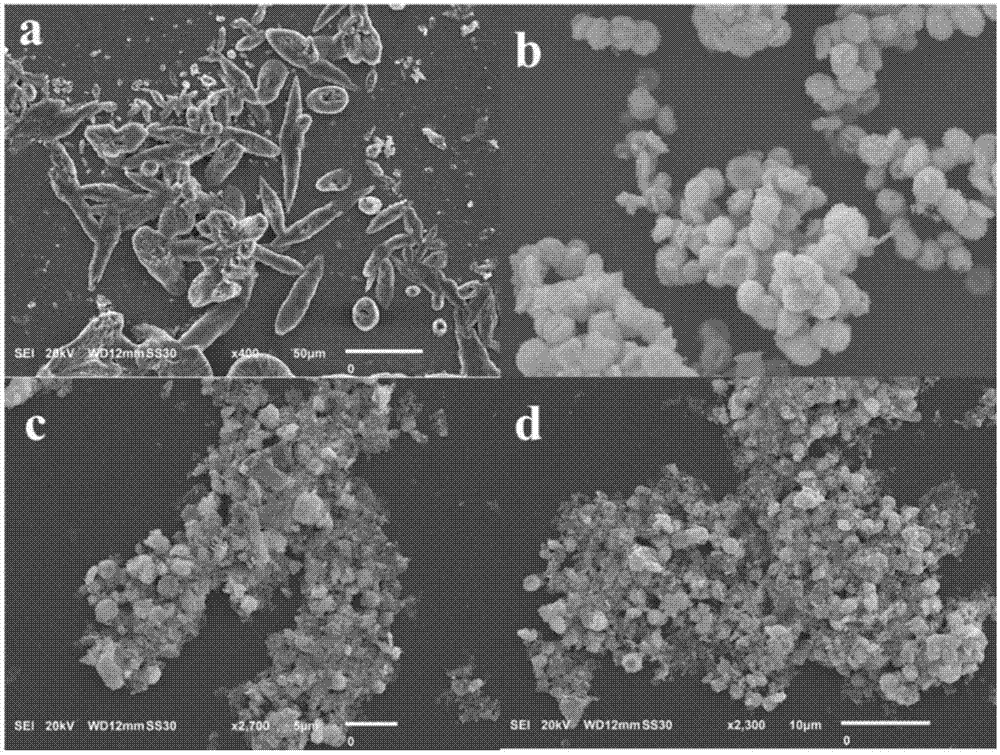

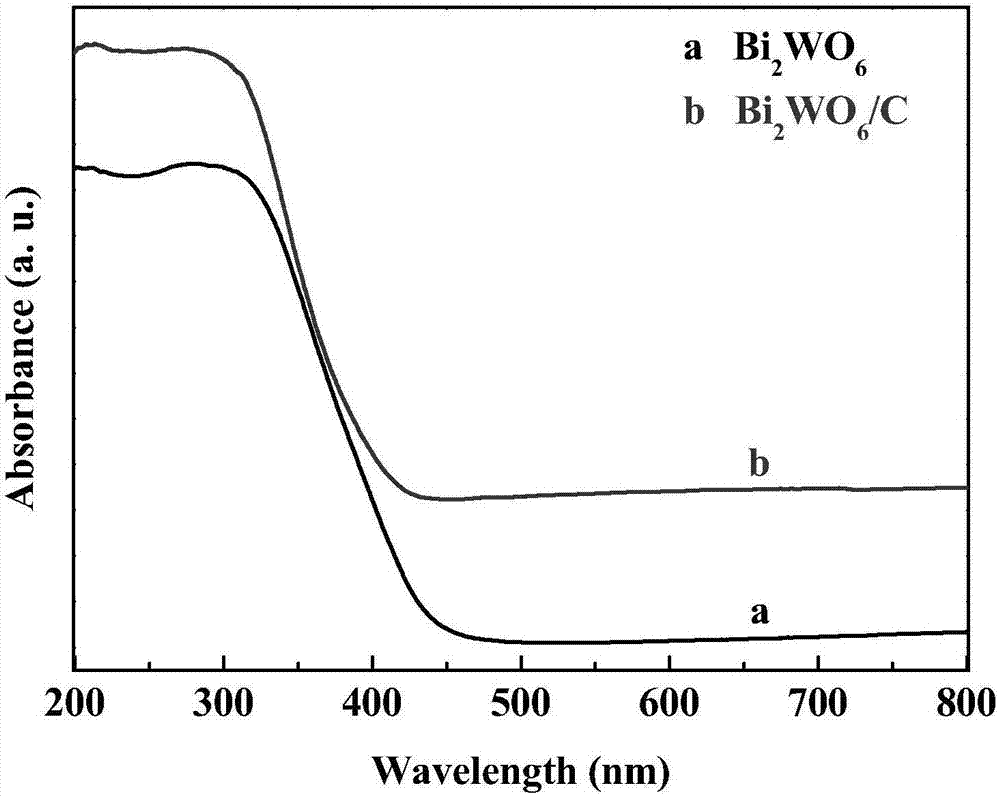

Preparation method and use of peach blossom biomass carbon-modified Bi2WO6 composite photocatalyst

A biomass carbon, composite light technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., to achieve stable performance, improve photocatalytic effect, and wide source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of Bi modified with peach and peanut substance carbon 2 WO 6 The preparation method of the composite photocatalyst, the steps are as follows:

[0043] Step 1. Peach blossom precursor treatment:

[0044] Pick up the withered peach blossoms, wash them with water to remove the dirt and dust on the surface, then wash with deionized water, dry at 60-80℃, smash them in a grinder, sieving, and obtain peach blossom powder for later use;

[0045] Step 2. Preparation of biomass carbon:

[0046] Take the peach blossom powder obtained in step 1 and add it to deionized water, seal and magnetically stir until it is evenly dispersed. After sonication, let it stand still, add a certain amount of NaOH solution, heat in a water bath, stir magnetically, and then dilute with H 2 SO 4 Adjust the pH of the solution to neutral and dry in vacuum to obtain a solid product, which is ground; then the ground solid product is placed in a porcelain boat and placed in a tube furnace N 2 Calcining in an...

Embodiment 1

[0054] In step 1, the mass of the picked peach blossoms is 200g.

[0055] In step 2, the amount of peach blossom powder used is 2g, the amount of deionized water used is 30mL, and the NaOH solution is 5mL; the NaOH and H 2 SO 4 The concentration is 1mol·L -1 . The calcination temperature is 500°C and kept at this constant temperature for 4h, and the heating rate is both 2.3°C·min -1 The temperature of the vacuum drying is 60°C.

[0056] In step 3, the Bi(NO 3 ) 3 ·5H 2 The amount of O is 1.0g, the amount of acetic acid used is 30mL; the amount of Na used 2 WO 4 ·2H 2 The amount of O is 0.3g, and the amount of deionized water is 50mL; the heating temperature is 180°C, and the heating time is 20h.

[0057] In step 4, the Bi 2 WO 6 The mass ratio to C is 4:1; the ultrasonic time is 2h, the stirring reaction time at the constant temperature is 3h, and the constant temperature temperature is 70°C.

[0058] Take 0.05g of Bi obtained in step 4 2 WO 6 / C added to 100mL contains 20mg L -1 In t...

Embodiment 2

[0060] In step 1, the mass of the picked peach blossoms is 200g.

[0061] In step 2, the amount of peach blossom powder used is 1g, the amount of deionized water used is 15mL, and the NaOH solution is 5mL; the NaOH and H 2 SO 4 The concentration is 1mol·L -1 . The calcination temperature is 450°C and kept at this constant temperature for 4h, and the heating rate is 1.0°C·min. -1 . The temperature of the vacuum drying is 70°C.

[0062] In step 3, the Bi(NO 3 ) 3 ·5H 2 The amount of O is 0.5g, the amount of acetic acid used is 15mL; the amount of Na used 2 WO 4 ·2H 2 The dosage of O is 0.1 g of deionized water and the dosage of 20 mL; the heating temperature is 180° C., and the heating time is 20 h.

[0063] In step 4, the Bi 2 WO 6 The mass ratio to C is 1:1; the ultrasound time is 1 h, the stirring reaction time at the constant temperature is 2 h, and the constant temperature temperature is 60°C.

[0064] Take 0.05g of Bi obtained in step 4 2 WO 6 / C added to 100mL contains 20mg L -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com