Pneumatic driven robot tool exchanging device

A technology of tool exchange and pneumatic drive, applied in the direction of manufacturing tools, manipulators, chucks, etc., can solve the problems of complex system structure and control methods, insufficient safety, and poor versatility, and achieve easy disassembly, good safety, and universal good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

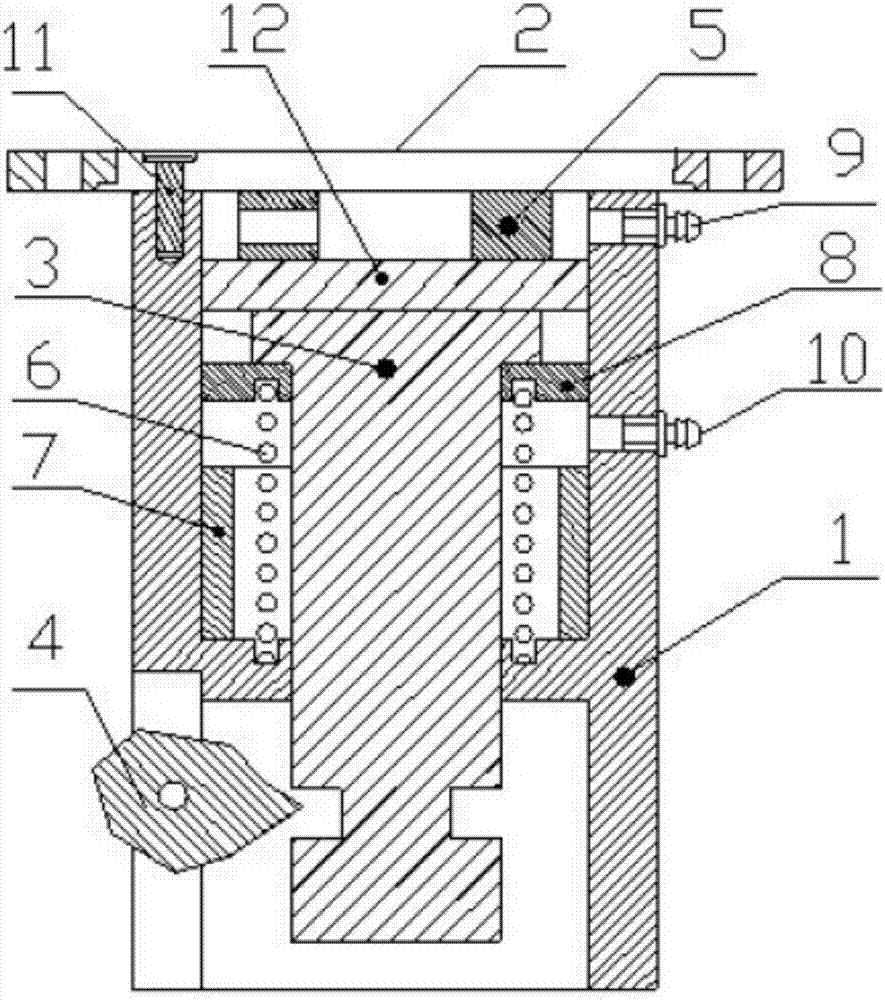

[0021] Such as figure 1 As shown, the robot side module of the present invention is mainly composed of a housing 1, a robot side connecting plate 2, a valve core 3, a cam 4, an upper limit ring 5, a spring 6, a lower limit ring 7, a spring cover plate 8, and the cam retracts compressed air. The interface 9, the cam protruding compressed air interface 10, the countersunk bolt 11, and the valve core piston 12 are composed. The bottom of the inner cavity of the shell 1 supports the spring 6, and the spring 6 covers the spring cover plate 8, the spring cover plate 8 supports the valve core 3, the lower part of the valve core piston 12 is in contact with the top of the valve core 3, and the upper part of the valve core piston 12 is fixed with a circular upper limit Circle 5, robot side connecting plate 2 is fixed with housing 1 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com