Low-concentration gas power generating system based on pulse combustion

A low-concentration gas, pulsating combustion technology, applied in the burner, combustion method, combustion type, etc., can solve the problem of low gas concentration and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

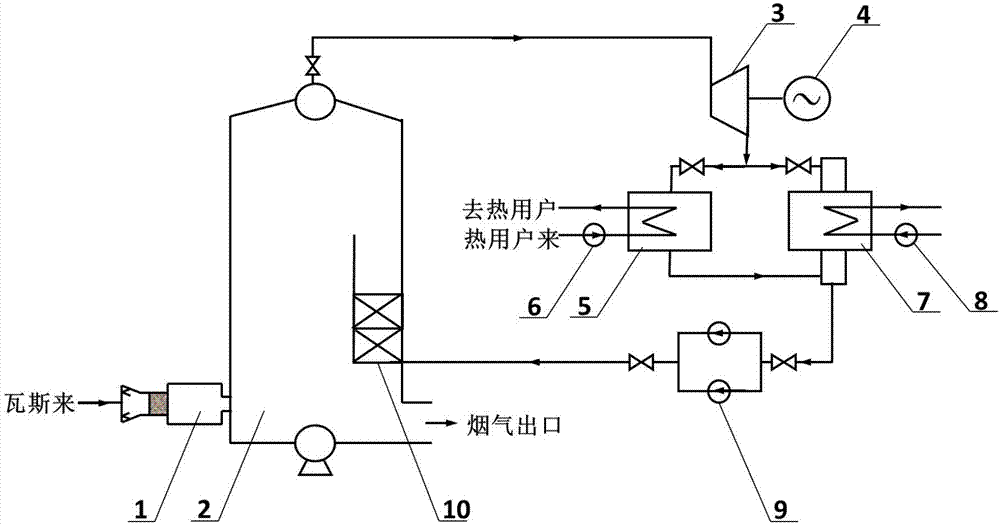

[0014] Attached below figure 1 The present invention is described further.

[0015] as attached figure 1 , a low-concentration gas power generation system based on pulsating combustion proposed by the present invention, including pulsating burner 1, waste heat boiler 2, screw expansion unit 3, generator 4, heat supply heat exchanger 5, heating circulating water pump 6, atmospheric Type condenser 7, cooling water circulation pump 8, feed water pump 9 and economizer 10, characterized in that the pulsation burner 1, waste heat boiler 2 and screw expansion unit 3 are combined; Combustion, release heat in waste heat boiler 2, heat feed water and generate steam; steam enters screw expansion unit 3 to drive generator 4 to generate electricity; The heat is taken away, and the condensed water enters the feed water pump 9; the other part of the exhaust steam enters the atmospheric condenser 7, and the heat is taken away by the circulating water provided by the cooling water circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com