Abrasive drill for robot-assisted cervical intervertebral disc replacement surgery system

A robot-assisted, cervical intervertebral disc technology, which is applied in the field of grinding and drilling, can solve the problems of not using a cervical intervertebral disc replacement surgical system for grinding and drilling, and achieves the effects of compact structure, good grinding effect and high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

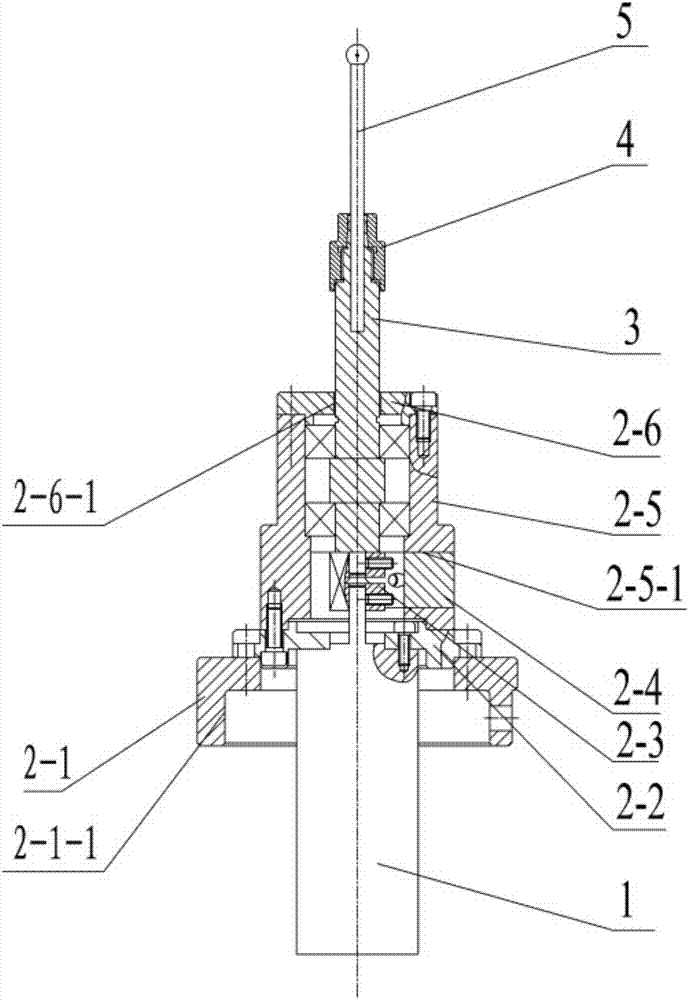

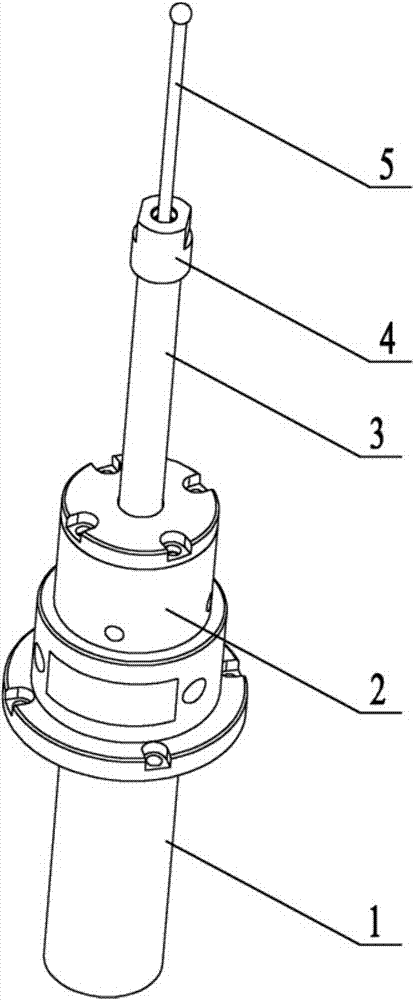

[0012] Specific implementation mode one: as Figure 1~2 As shown, the burr used in the robot-assisted cervical disc replacement surgery system of this embodiment includes a high-speed DC motor 1, a motor holder 2, a burr drive shaft 3 and a grinding head 5, and the motor holder 2 includes a connecting platform 2 -1, fixed ring 2-2, shaft coupling 2-3, housing 2-5 and end cover 2-6, one end of the fixed ring 2-2 passes through the output shaft of the high-speed DC motor 1 and is fixed On the end face of the output shaft end of the high-speed DC motor 1, the other end of the fixed ring 2-2 is fixed on the end face of the housing 2-5, and one end of the milling drive shaft 3 is mounted on the housing 2 through a bearing. -5, one end of the drill drive shaft 3 is affixed to the output shaft of the high-speed DC motor 1 through a coupling 2-3, and the grinding head 5 is fixed on the other end of the drill drive shaft 3, so A first central through hole 2-6-1 is processed in the axi...

specific Embodiment approach 2

[0013] Embodiment 2: The shaft coupling 2-3 in this embodiment is a diaphragm type high torque coupling. This design ensures the high efficiency of power transmission, eliminates the problem of axial eccentricity, and facilitates card installation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

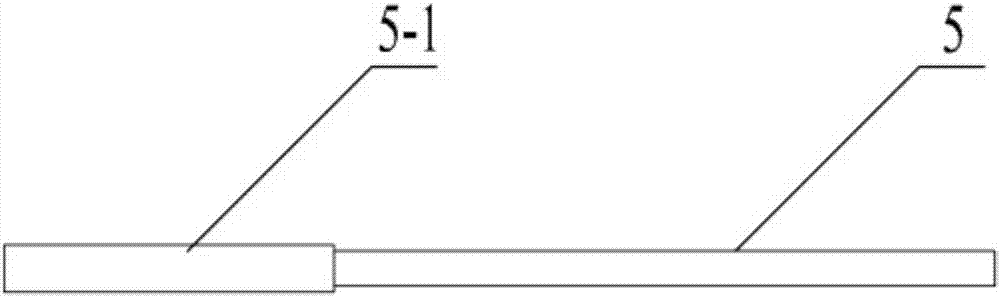

[0014] Specific implementation mode three: as image 3 As shown, the grinding end of the grinding head 5 is a cylindrical grinding head 5-1. With such a design, it can be used to grind the planes of the rostral and caudal endplates of the cervical spine. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com