Glass fiber fabric and sewing method thereof

A glass fiber and fabric technology, applied in the field of glass fiber fabric and its stitching, can solve the problems of failing to meet the design requirements of the blade, easy uneven surface, easy wrinkling, etc. good pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

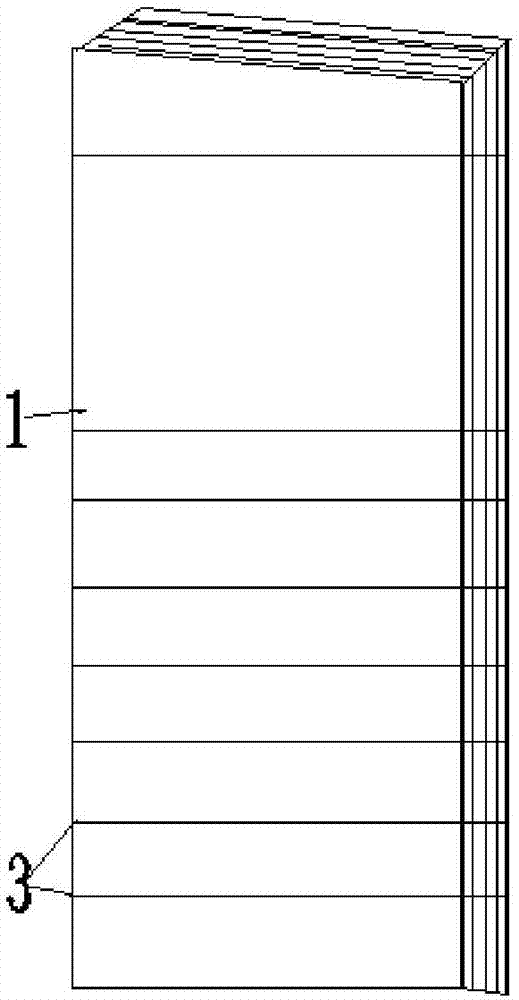

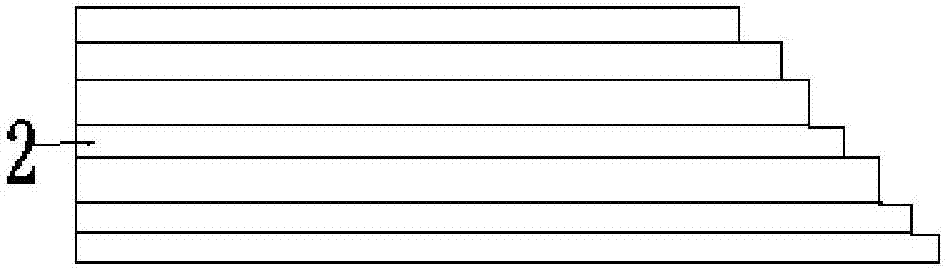

[0058] Such as Figure 1-Figure 2 as shown,

[0059]A glass fiber fabric, comprising a multi-tissue unit 1, each tissue unit 1 is composed of a plurality of single-layer fabrics 2, the width of each single-layer fabric 2 is different, and a plurality of single-layer fabrics 2 are arranged up and down, and a plurality of The area of the single-layer fabric 2 gradually decreases from bottom to top, one side of the multiple single-layer fabrics 2 is aligned, and the other side of the multiple single-layer fabrics 2 is arranged on a stepped slope.

[0060] In the further optimized technical solution of the present invention, each fabric unit 1 is composed of 7 single-layer fabrics 2 .

[0061] In the further optimized technical solution of the present invention, the front edges of the multiple single-layer fabrics 2 are aligned on one side, and the rear edges of the multiple single-layer fabrics are arranged on a stepped slope.

[0062] In a further optimized technical solutio...

Embodiment 2

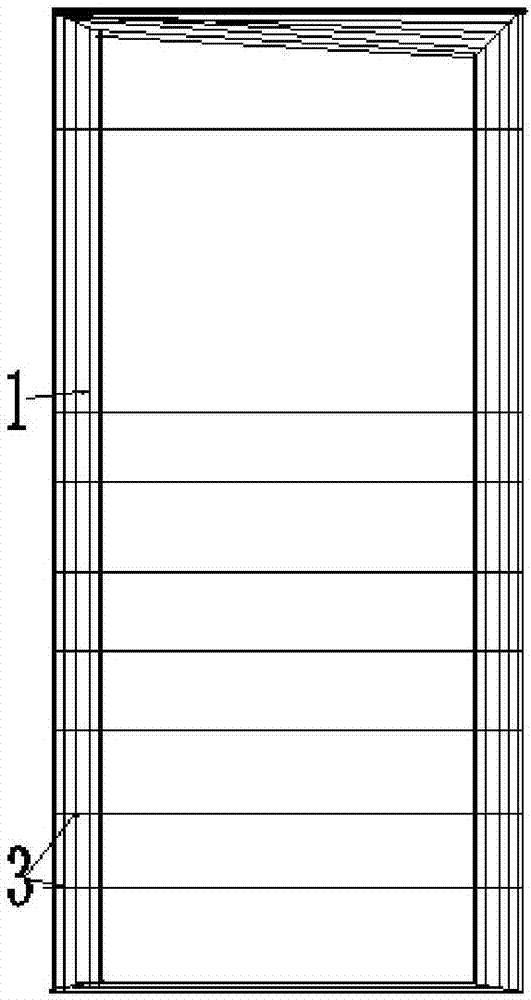

[0073] A glass fiber fabric, including a multi-tissue unit 1, each tissue unit 1 is composed of 6 single-layer fabrics 2, the width of the 6 single-layer fabrics 2 is different, the 6 single-layer fabrics 2 are set up and down, and 6 The area of the single-layer fabric 2 gradually decreases from bottom to top, and the front edges of the six single-layer fabrics 2 are not aligned on one side and are arranged on a stepped slope; the rear edges of the six single-layer fabrics 2 are arranged on a stepped slope (the front edge and the trailing edge are artificially defined, and the leading edge and the trailing edge refer to the two sides of a single-layer fabric), such as image 3 and Figure 4 shown.

[0074] In the further optimized technical solution of the present invention, the six single-layer fabrics 2 are fixed together by sewing.

[0075] In the further optimized technical solution of the present invention, each tissue unit 1 is provided with eight stitching lines 3 ....

Embodiment 3

[0086] The difference from Example 1 is that a glass fiber fabric includes multiple tissue units 1, and each tissue unit 1 is composed of 8 single-layer fabrics 2, and the width of each single-layer fabric 2 is different, and the 8 single-layer fabrics Layers of fabric 2 are arranged up and down, and the area of the eight single-layer fabrics 2 gradually decreases from bottom to top. One side of the eight single-layer fabrics 2 is aligned, and the other side of the eight single-layer fabrics 2 is arranged on a stepped slope. The front edges of the eight single-layer fabrics 2 are aligned on one side, and the rear edges of the eight single-layer fabrics 2 are arranged on a stepped slope.

[0087] In the further optimized technical solution of the present invention, the eight single-layer fabrics 2 are fixed together by sewing.

[0088] The 8 single-layer fabrics all use the same biaxial fiberglass composite mat as Figure 5-Figure 8 As shown, the biaxial glass fiber composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com