Automatic paper laying machine for glass stacking

A stacking and glass technology, applied in the field of glass stacking automatic paper laying machines, can solve the problems of low work efficiency, undifferentiated efficiency, and high production costs, reduce machinery and labor costs, avoid paper tearing, and run smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

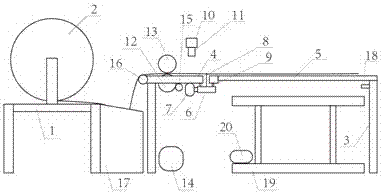

[0015] Embodiment one: if figure 1 The shown automatic paper laying machine for glass stacking includes a roll rack 1, a paper feeding mechanism, a paper cutting mechanism, and a lift table 19. The roll rack 1 is provided with a roll 2, and beside the roll rack 1 is a A frame 3 consisting of a paper platen 4 and two guide plates 5 connected in parallel to the platen; a buffer box 17 is provided between the platen 4 and the roll frame 1; on the frame There is a paper feeding mechanism 13 that pushes the paper in the buffer box to the guide plate horizontally, and a cutting mechanism that cuts the paper; a lifting platform 19 is arranged between the two guide plates 5, and a lifting platform 19 is arranged on the guide plate. A photoelectric switch 18 is provided, and when the photoelectric switch detects that the glass on the top of the lifting platform exceeds the set height, the lifting motor in the lifting platform can be controlled to make the top of the lifting platform de...

Embodiment 2

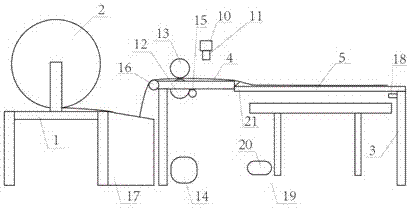

[0020] Embodiment two: if figure 2 As shown, another implementation of the paper cutting mechanism is: the height of the plane where the guide plate 5 is located is lower than the plane of the platen platform 4, and the highest point of the glass stack on the lifting platform 19 is the photoelectric switch 18 The height is lower than the height of the guide plate 5, and there is a height difference between the highest point of the glass stack and the plane of the paper platen, so that when a new glass is lowered onto the stack, it will press the paper on the guide plate to the previous glass above; a cutter is provided between the guide plate and the platen platform, the height of the blade of the cutter is lower than the plane of the platen platform, and higher than the connection line between the outermost end of the platen platform and the innermost end of the highest part of the glass stack, When the paper is pressed down, it will contact the cutting knife to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com