Thermochromic process for noble metal

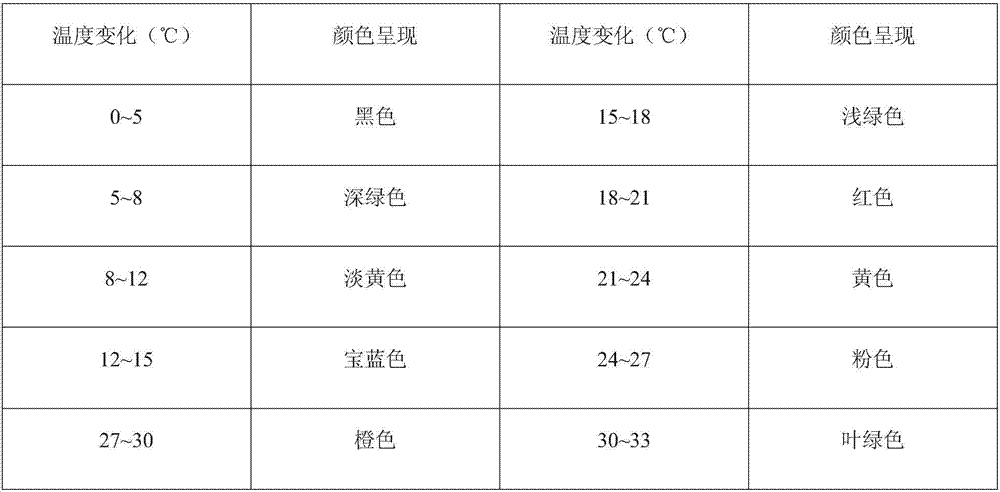

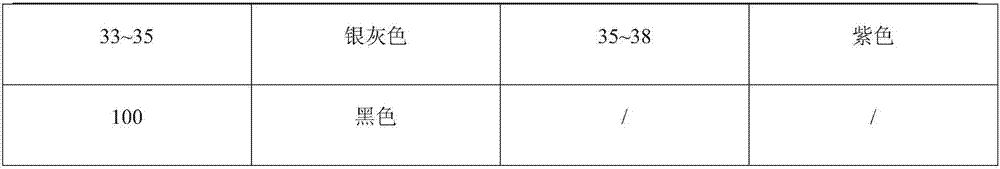

A technology of thermochromic and thermochromic pigments, applied in the field of thermochromic technology, can solve the problems of single decoration color of precious metals, unable to meet the demand for ornamental properties of precious metals, limited decoration effect, etc., to achieve rich and brilliant colors and improve decoration effect. , the effect of long quality shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, some non-limiting examples are further disclosed below to further describe the present invention in detail. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0035] Materials such as paints, thermochromic pigments, curing agents, and defoamers used in the present invention can be purchased from the market or can be prepared by the method described in the present invention.

Embodiment 1

[0037] Black primer configuration:

[0038] Add 10 grams of black paint to 3.6 grams of Baxxodur ECX2221 modified fatty amine curing agent, stir evenly in the cup for 3 minutes, then put it into the vacuum machine to extract the bubbles generated during the stirring process, and finally put it in a plastic bag for storage spare.

[0039] Thermochromic paint configuration:

[0040] First, thermochromic pigment-water-based methacrylate mixture: add 4.2 grams of thermochromic pigment and 16.3 grams of water-based methacrylate into the container, stir evenly for 5 minutes, then seal and store at 15-20 degrees Celsius standby in the environment;

[0041] Then, temperature-sensitive color-changing pigment-E44 bisphenol A type epoxy resin water-based curing agent mixture: 3.9 grams of temperature-sensitive color-changing pigment and 15.8 grams of E44 bisphenol A type epoxy resin water-based curing agent are added in the container, and stirred evenly for 5 minutes, Then seal and st...

Embodiment 2

[0051] Black primer configuration:

[0052] Add 10 grams of black paint to 3.5 grams of Baxxodur ECX1222 modified alicyclic amine curing agent, stir evenly in the cup for 3 minutes, then put it into the vacuum machine to extract the bubbles generated during the stirring process, and finally put it into a plastic bag Save for later.

[0053] Thermochromic paint configuration:

[0054] First, thermochromic pigment-water-based methacrylate mixture: add 3.8 grams of thermochromic pigment and 16.1 grams of water-based methacrylate into the container, stir evenly for 5 minutes, then seal and store at 15-20 degrees Celsius standby in the environment;

[0055] Then, temperature-sensitive color-changing pigment-E51 bisphenol A type epoxy resin water-based curing agent mixture: 4.1 grams of temperature-sensitive color-changing pigment and 16.2 grams of E51 bisphenol A type epoxy resin water-based curing agent are added in the container, and stirred evenly for 5 minutes, Then seal and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com