Easy-to-rework foam dual-layer adhesive tape for assembling television

A TV, foam technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor adhesive tape adhesion, difficult to rework, poor stability, etc., and achieve good adhesion performance and foaming speed. Fast and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

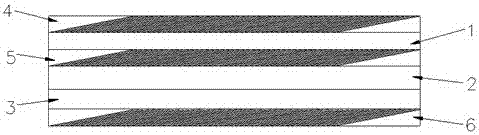

[0016] see figure 1 , the present invention provides a technical solution: a kind of reworkable double-layer foam adhesive tape for TV assembly, comprising a thermoplastic polyurethane layer 1, a PU elastic layer 2 and a PET layer 3, and the upper surface of the thermoplastic polyurethane layer 1 is coated with a first acrylic acid A pressure-sensitive adhesive layer 4, the lower surface of the thermoplastic polyurethane layer 1 is bonded to the PU elastic layer 2 through the second acrylic pressure-sensitive adhesive layer 5, the lower surface of the PU elastic layer 2 is provided with a PET layer 3, and the outer surface of the PET layer 3 is Coated with a third acrylic pressure-sensitive adhesive layer 6 .

[0017] In the present embodiment, the PU elastic layer 2 is filled with foam material, and the foam material components include 50 parts of water-based polyester resin, 8 parts of structural reinforcing agent, 8 parts of foam stabilizer, 3 parts of carbon black by weigh...

Embodiment 2

[0023] An easy-to-rework foam double-layer tape for TV assembly, comprising a thermoplastic polyurethane layer 1, a PU elastic layer 2 and a PET layer 3, the upper surface of the thermoplastic polyurethane layer 1 is coated with a first acrylic pressure-sensitive adhesive layer 4, the thermoplastic The lower surface of the polyurethane layer 1 is bonded to the PU elastic layer 2 through the second acrylic pressure-sensitive adhesive layer 5, the lower surface of the PU elastic layer 2 is provided with a PET layer 3, and the outer surface of the PET layer 3 is coated with a third acrylic pressure-sensitive adhesive Layer 6.

[0024] In the present embodiment, the PU elastic layer 2 is filled with foam material, and the foam material components include 70 parts by weight of water-based polyester resin, 17 parts of structural reinforcing agent, 12 parts of foam stabilizer, and 10 parts of carbon black. 14 parts of leveling agent, 8 parts of matting agent, 12 parts of foam stabili...

Embodiment 3

[0030] An easy-to-rework foam double-layer tape for TV assembly, comprising a thermoplastic polyurethane layer 1, a PU elastic layer 2 and a PET layer 3, the upper surface of the thermoplastic polyurethane layer 1 is coated with a first acrylic pressure-sensitive adhesive layer 4, the thermoplastic The lower surface of the polyurethane layer 1 is bonded to the PU elastic layer 2 through the second acrylic pressure-sensitive adhesive layer 5, the lower surface of the PU elastic layer 2 is provided with a PET layer 3, and the outer surface of the PET layer 3 is coated with a third acrylic pressure-sensitive adhesive Layer 6.

[0031] In the present embodiment, the PU elastic layer 2 is filled with a foam material, and the foam material components include 55 parts of water-based polyester resin, 10 parts of structural reinforcing agent, 9 parts of foam stabilizer, and 4 parts of carbon black by weight. 5 parts, 7 parts of leveling agent, 3 parts of matting agent, 5 parts of foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com