Fish oil deacidification process

A deacidification and process technology, applied in the direction of fat oil/fat refining, other chemical processes, fat production, etc., can solve the problems of weakened intermolecular force, decreased stability, lowered thermal decomposition temperature, etc., to improve adsorption capacity and cost Low, the effect of improving the adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

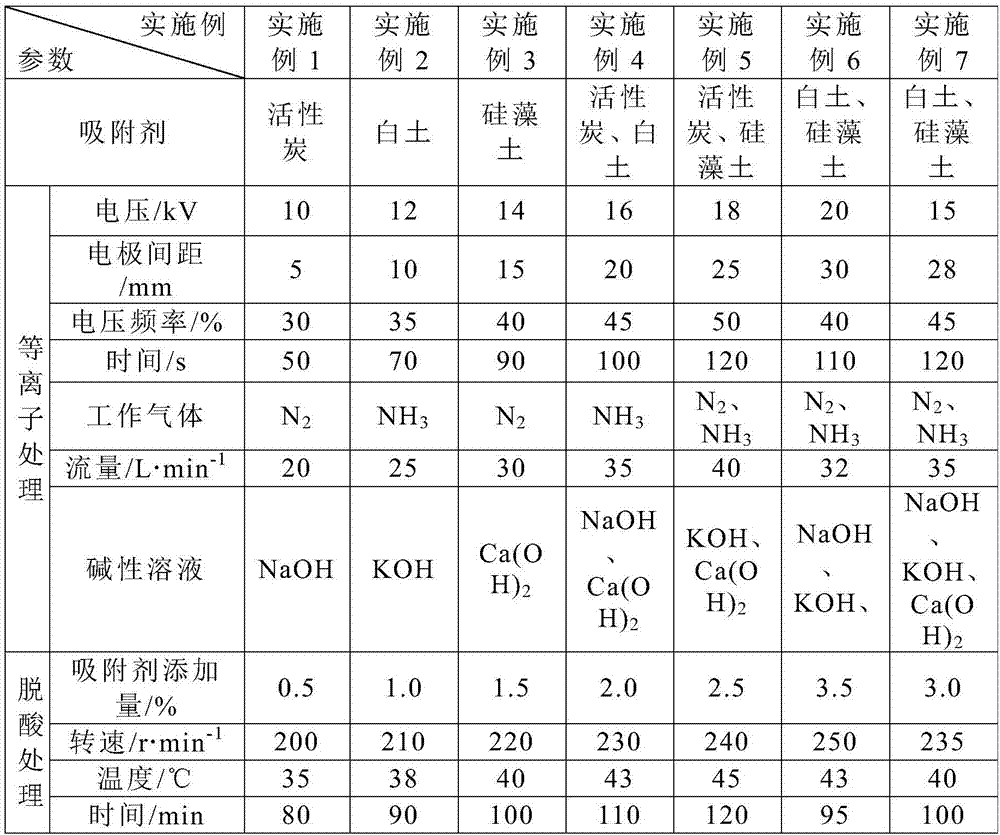

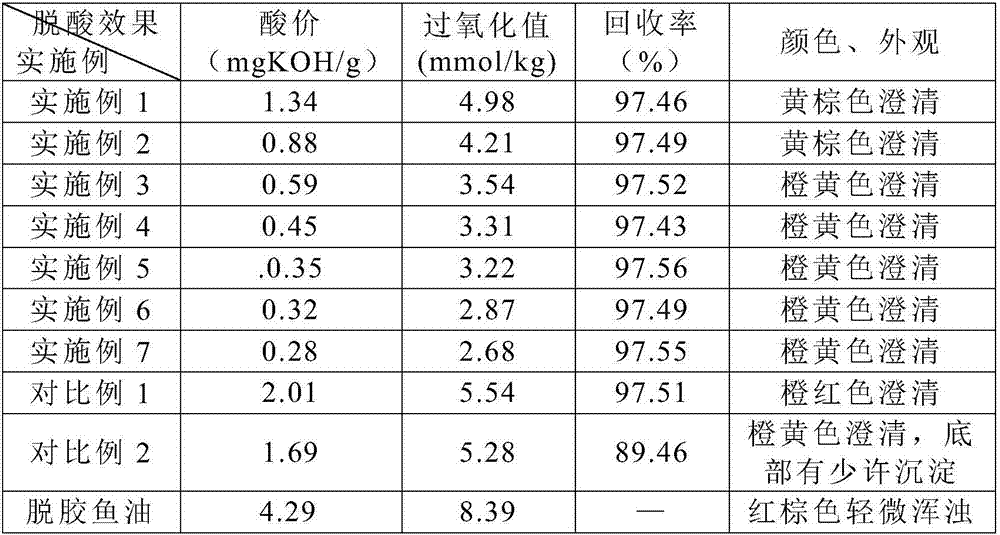

Embodiment 1~7

[0039] The deacidification process in the present invention includes the following steps:

[0040] Put the adsorbent into the dielectric barrier plasma generator whose barrier medium is polymethyl methacrylate, adjust the voltage to 10-20kV, the distance between the upper and lower electrodes is 5-30mm, and the voltage frequency is 30-50kHz. The gas first passes through a bubbler filled with alkaline solution, and then into the plasma generator. Adjust the working gas flow to 20~40L·min -1 , Turn on the AC power switch of the plasma generator, perform plasma treatment for 50~120s, and the working gas is N 2 , NH 3 One or two of them, the alkaline solution is NaOH solution, KOH solution, Ca(OH) 2 One or more in the solution, the adsorbent is one or more of activated carbon, clay, and diatomaceous earth; then continue to pass N 2 30~60s;

[0041] Afterwards, remove the adsorbent, store it in an inert gas or add it to the degummed fish oil immediately. The addition amount is 0.5 to 3.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com