Copper ball preparing method

A technology of copper balls and preparation steps, which is applied in the field of preparation of copper balls, can solve the problems of low material utilization rate, complex process, long cycle, etc., and achieve the effects of optimizing the preparation process, speeding up the preparation efficiency, and reducing quenching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

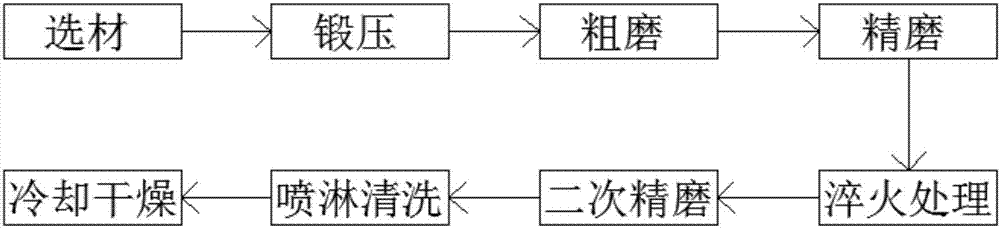

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of copper ball, concrete preparation steps are as follows:

[0028] Step 1: Material selection: Under the condition of 25°C, select a copper block with a copper mass fraction between 90% and 95% for forging;

[0029] Step 2: Forging: Place the copper blocks in Step 1 on copper molds with a mold diameter of 5.2 mm and forge them into ball blanks;

[0030] Step 3: Coarse grinding: Place the ball blank in step 2 in the grinder, use the coarse grinding wheel in the grinder to pressurize the ball blank, remove the outer ring belt and two poles on the ball blank, and file it The allowable error range is between 0.05 and 0.1mm, if it exceeds this range, it will be judged as unqualified;

[0031] Step 4: Fine grinding: Place the coarsely ground ball embryos in step 3 in the fine grinding machine, use the fine grinding wheel in the fine grinder to pressurize and file the coarsely ground ball embryos, and grind the coarsely ground ball ...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of copper ball, concrete preparation steps are as follows:

[0037] Step 1: Material selection: Under the condition of 25°C, select a copper block with a copper mass fraction between 90% and 95% for forging;

[0038] Step 2: Forging: Place the copper blocks in Step 1 on copper molds with a mold diameter of 5.2 mm and forge them into ball blanks;

[0039] Step 3: Coarse grinding: Place the ball blank in step 2 in the grinder, use the coarse grinding wheel in the grinder to pressurize the ball blank, remove the outer ring belt and two poles on the ball blank, and file it The allowable error range is between 0.05 and 0.1mm, if it exceeds this range, it will be judged as unqualified;

[0040] Step 4: Fine grinding: Place the coarsely ground ball embryos in step 3 in the fine grinding machine, use the fine grinding wheel in the fine grinder to pressurize and file the coarsely ground ball embryos, and grind the coarsely ground ball ...

Embodiment 3

[0045] Embodiment 3: a kind of preparation method of copper ball, concrete preparation steps are as follows:

[0046] Step 1: Material selection: Under the condition of 25°C, select a copper block with a copper mass fraction between 90% and 95% for forging;

[0047] Step 2: Forging: Place the copper blocks in Step 1 on copper molds with a mold diameter of 5.2 mm and forge them into ball blanks;

[0048] Step 3: Coarse grinding: Place the ball blank in step 2 in the grinder, use the coarse grinding wheel in the grinder to pressurize the ball blank, remove the outer ring belt and two poles on the ball blank, and file it The allowable error range is between 0.05 and 0.1mm, if it exceeds this range, it will be judged as unqualified;

[0049]Step 4: Fine grinding: Place the coarsely ground ball embryos in step 3 in the fine grinding machine, use the fine grinding wheel in the fine grinder to pressurize and file the coarsely ground ball embryos, and grind the coarsely ground ball e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com