Push rod controller

A controller and push rod technology, used in construction, door/window fittings, wing fan control mechanisms, etc., to achieve high efficiency, avoid electrical spark problems, and low no-load current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and the drawings, and the content mentioned in the embodiments does not limit the present invention.

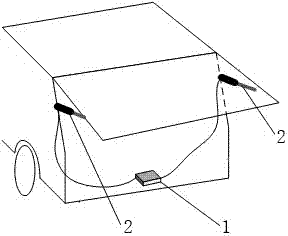

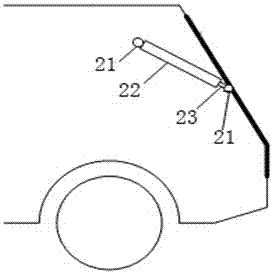

[0022] In this embodiment, the control of the opening and closing of the tailgate of the automobile is implemented as a scene, and the push rod controller is preferably used to control the double push rod device. Such as figure 1 This embodiment provides a dual push rod control system, which includes a controller 1, two push rod devices 2 and a zipper motor installed on the tailgate of an automobile. The controller 1 is electrically connected to the two push rod devices 2, respectively, The zipper motor is electrically connected to the controller 1.

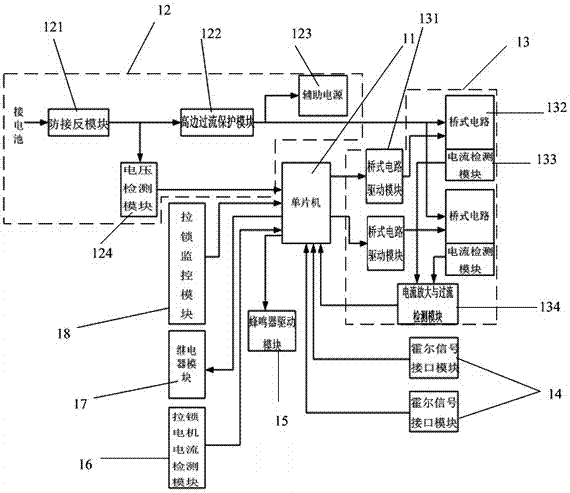

[0023] A putter controller, such as figure 2 , Including single-chip microcomputer (the preferred model is SH79F1611), power module 12, zipper monitoring module 18, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com