Catalytic combustion purification process and device

A catalytic combustion and purification process technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of catalyst bed overheating, poor temperature control, etc., to prevent overheating, reduce load, and balance temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

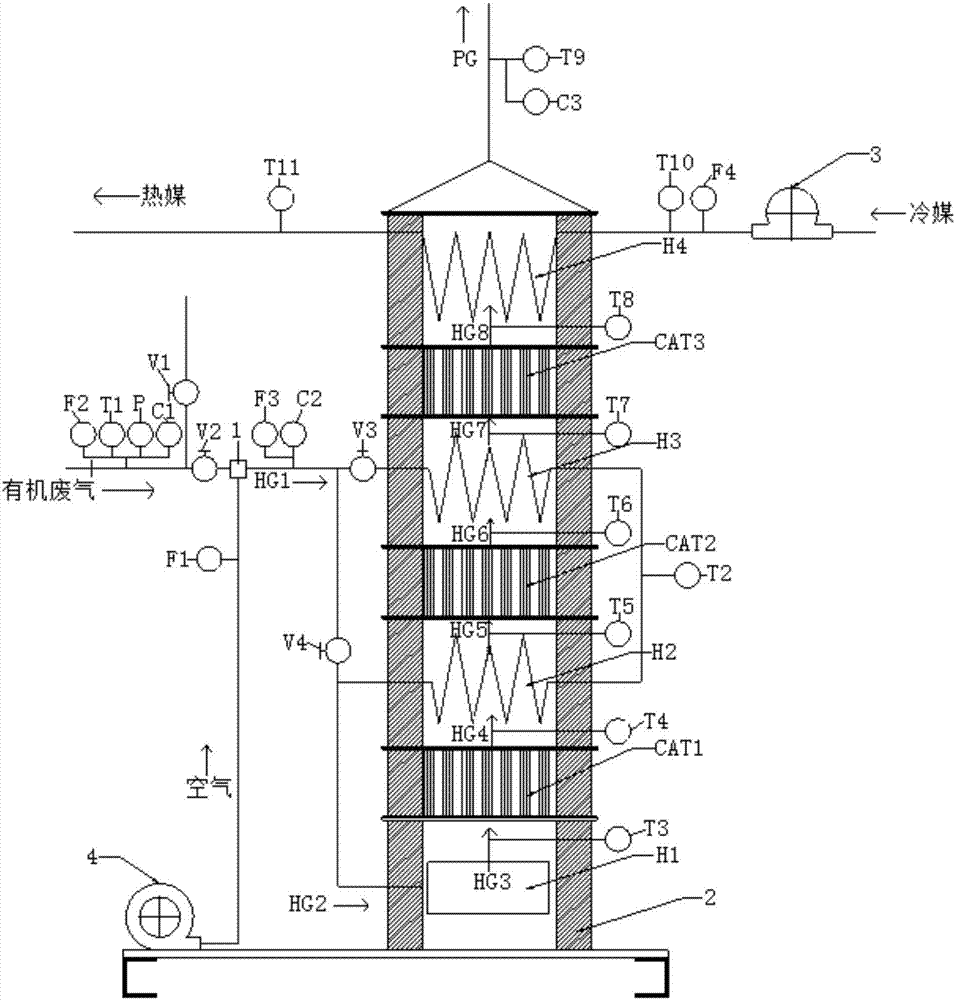

[0053] This embodiment provides a catalytic combustion purification process, such as figure 1 shown, including the following steps:

[0054] 1) The organic waste gas is taken out from the organic waste gas source, and the composition content of the organic waste gas is as follows: CH 4 : 35960mg / m 3 , Ethane equivalent converted from hydrocarbons above C2: 6179mg / m 3 , CO 2 12.0%, O 2 0.30%, the rest is N 2 , the flow rate of the organic waste gas is 2700m 3 / h, before the organic waste gas enters the mixing device, it is pre-desulfurized and equipped with a fire arresting device. The organic waste gas has its own pressure and can directly enter the mixing device without fan drainage;

[0055] Control the air volume adjustment capacity of the frequency conversion fan to 90% of the safe theoretical metering ratio. In order to facilitate the transformation of organic waste gas and control the appropriate excess of oxygen, under the condition of stable concentration, the ai...

Embodiment 2

[0060] This embodiment provides a catalytic combustion purification process, comprising the following steps:

[0061] 1) The organic waste gas is taken out from the organic waste gas source, and the composition content of the organic waste gas is as follows: CH 4 : 15000mg / m 3 , Ethane equivalent converted from hydrocarbons above C2: 5800mg / m 3 , CO 2 10.0%, O 2 0.50%, the rest is N 2 , before entering the mixing device, the organic waste gas is pre-desulfurized and equipped with a fire arresting device. The organic waste gas has its own pressure and can directly enter the mixing device without fan drainage;

[0062] Control the air volume adjustment capacity of the frequency conversion fan to be 50% of the safe theoretical metering ratio. In order to facilitate the transformation of organic waste gas and control the excess of oxygen, under the condition of stable concentration, the air volume introduced into the mixing device by the frequency conversion fan is 1000m 3 / h...

Embodiment 3

[0067] This embodiment provides a catalytic combustion purification process, comprising the following steps:

[0068] 1) Collect organic waste gas released during industrial production and methane gas released during oilfield exploitation to ensure that the total concentration of combustibles in the mixed organic waste gas composed of the two does not exceed 100,000mg / m 3 , after testing, the content of the components in the mixture of the two is as follows: CH 4 : 50000mg / m 3 , Ethane equivalent converted from hydrocarbons above C2: 8900mg / m 3 , CO 2 15.0%, O 2 0.60%, the rest is N 2 , before entering the mixing device, the organic waste gas is pre-desulfurized and equipped with a fire arresting device. The organic waste gas has its own pressure and can directly enter the mixing device without fan drainage;

[0069] Control the air volume adjustment capacity of the frequency conversion fan to be 150% of the safe theoretical metering ratio. In order to facilitate the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com