Melt-cast explosive digital development and manufacturing method

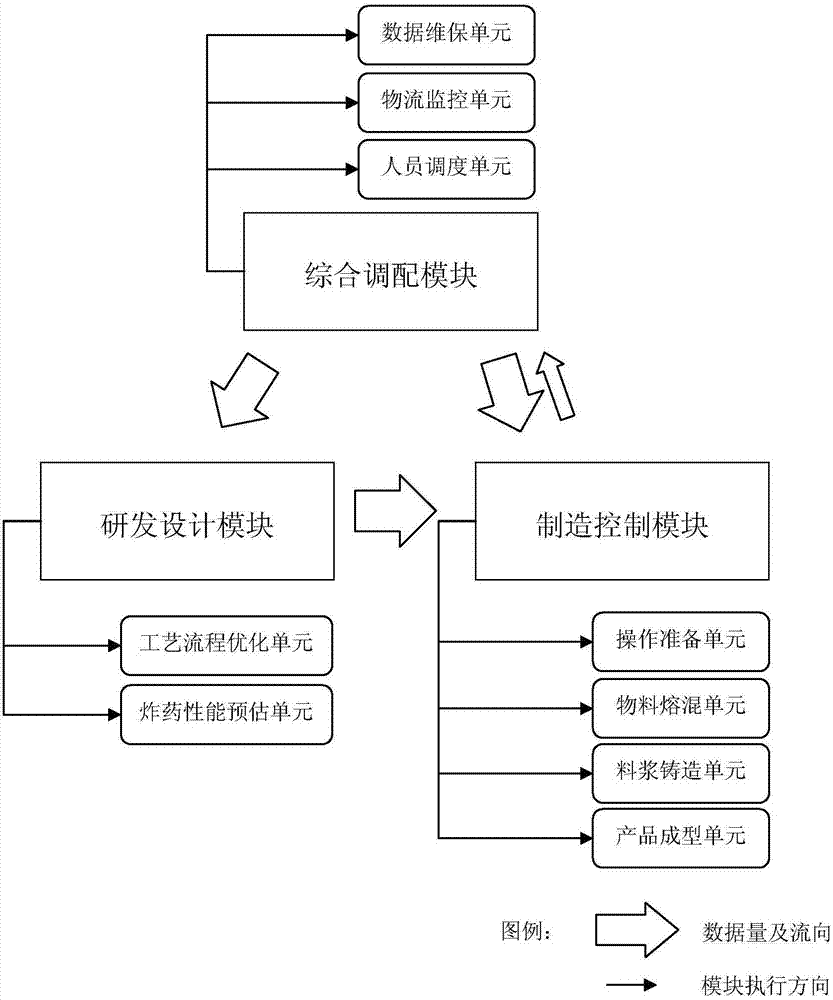

A technology of melting and casting explosives and manufacturing methods, which is applied in the direction of aromatic nitration composition, compressed gas generation, offensive equipment, etc., can solve the problems of low level of explosive control, low level of explosive product R&D and design, and single product types, etc., to achieve optimization Process parameters and product performance, improve the level of R & D design, the effect of data integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

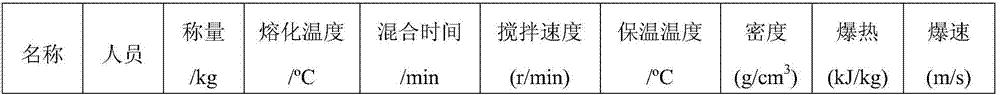

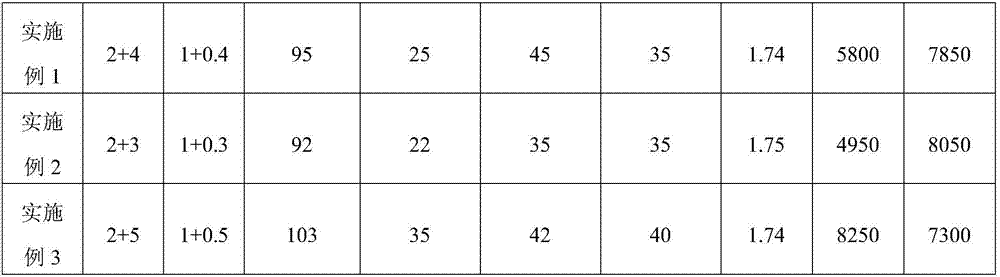

[0032] A method for digital R&D and manufacturing of fused and cast explosives, wherein the name of fused and cast explosives is Ex1, and the formula consists of TNT (TNT) 30 / Octogen (HMX) 62 / aluminum powder (Al) 5 / insensitive agent 3.

[0033] Step 1, run the comprehensive allocation module, and determine 2 R&D and design personnel to be responsible for R&D and design, and 4 manufacturing control personnel to be responsible for the production and manufacture of casting explosives. It is determined that the name code of the melt-cast explosive that needs to be developed and manufactured is Ex1, and the formula is composed of TNT (TNT) 30 / Octogen (HMX) 62 / Aluminum powder (Al)5 / Desensitizing agent 3. Record the total weight of raw material weighing as 1.4kg, of which 1.0kg is the effective target charge mass, and 0.4kg is the spare riser feeding charge mass. The composition of each component is calculated and recorded according to the total weight. Record and save the process d...

Embodiment 2

[0041] A method for digital R&D and manufacturing of melt-cast explosives, wherein the name of the melt-cast explosives is Ex2, and the formula consists of TNT (TNT) 30 / Octokin (HMX) 69 / microcrystalline wax (W) 1.

[0042] Step 1, run the comprehensive deployment module, and determine 2 R&D and design personnel to be responsible for R&D and design, and 3 manufacturing control personnel to be responsible for the production and manufacture of casting explosives. It is determined that the name code of the melt-cast explosive that needs to be developed and manufactured is Ex2, and the formula composition is TNT (TNT) 30 / Octokin (HMX) 69 / Microcrystalline Wax (W) 1. Record the total weight of raw material weighing as 1.3kg, of which 1.0kg is the effective target charge mass, and 0.3kg is the spare riser feeding charge mass. The composition of each component is calculated and recorded according to the total weight. Record and save the process data such as melting temperature, mixing...

Embodiment 3

[0050] A method for digital R&D and manufacturing of fused and cast explosives, wherein the name of the fused and cast explosive is Ex3, and the formula consists of 2,4-dinitroanisole (DNAN) 29 / RDX 52 / aluminum powder (Al) 17 / surface Active Agent (SA)2.

[0051] Step 1, run the comprehensive deployment module, and determine 2 R&D and design personnel to be responsible for R&D and design, and 5 manufacturing control personnel to be responsible for the production and manufacture of casting explosives. It is determined that the name code of the melt-cast explosive that needs to be developed and manufactured is Ex3, and the formula is composed of 2,4-dinitroanisole (DNAN) 29 / RDX 52 / aluminum powder (Al) 17 / surfactant ( SA) 2. Record the total weight of raw material weighing as 1.5kg, of which 1.0kg is the effective target charge mass, and 0.5kg is the spare riser feeding charge mass. The composition of each component is calculated and recorded according to the total weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com