Technique for extracting and purifying oleanolic acid and ursolic acid from sweet tea

A technology of oleanolic acid and process method, applied in organic chemistry, steroidal compounds, etc., can solve the problems of unreported extraction and purification process, and achieve the effects of long extraction time, low efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

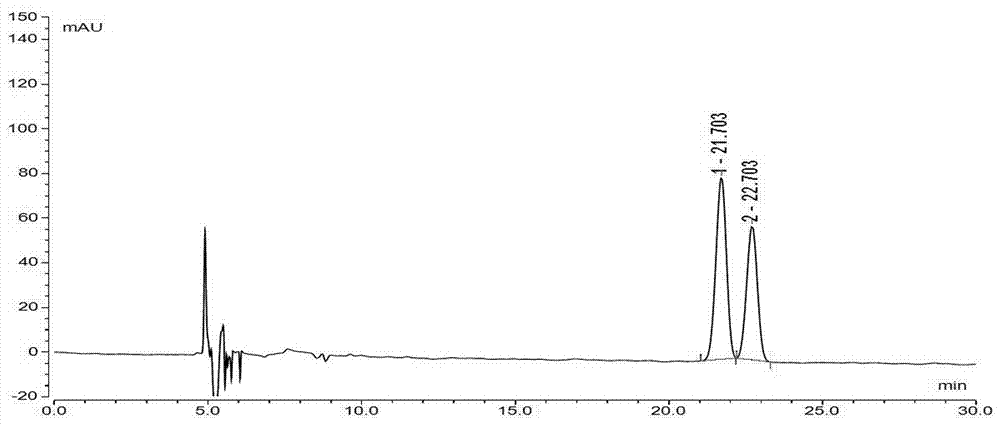

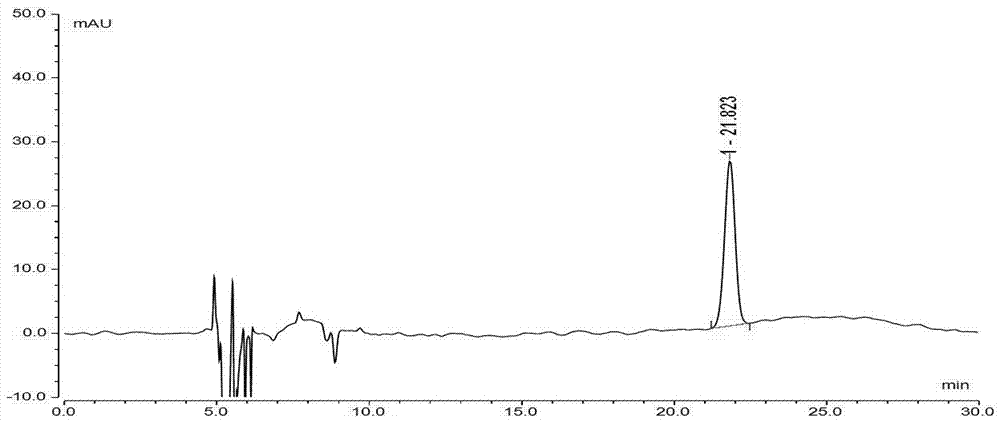

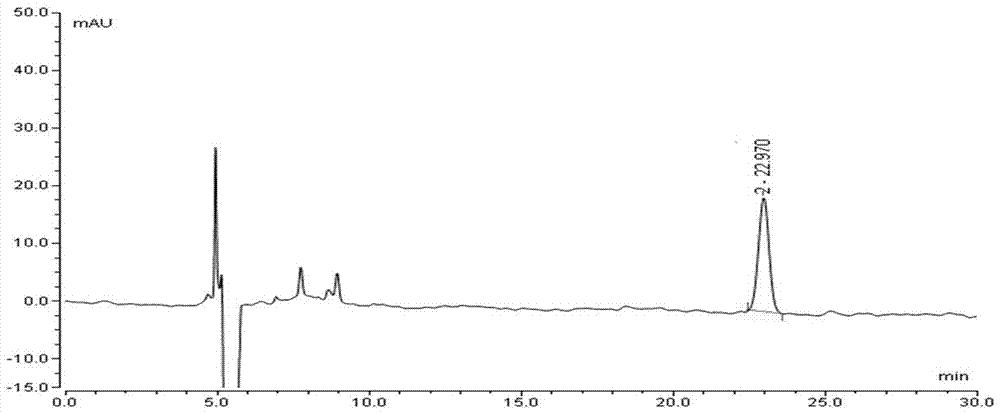

Image

Examples

Embodiment 1

[0021] A process for extracting and purifying oleanolic acid and ursolic acid from sweet tea, comprising the steps of:

[0022] (1) Take a sweet tea sample and crush it with a masher, weigh 150g of the sample, add 2 times its weight in absolute ethanol, ultrasonically extract at 25°C for 10min, and filter the extract with suction; wash with 300mL ethanol after suction filtration The residue 1 time, then suction filtration, the suction filtrate is combined with the extract for the first time, the combined extract is concentrated to obtain an extract, the obtained extract is dissolved in 30mL of chloroform, and the brown extract is obtained after concentration and recovery of chloroform;

[0023] (2) Add 30mL of 5% sodium hydroxide solution to the obtained extract, boil for 10min, suction filter while it is hot, put the filtrate in the refrigerator at 5-10℃ for 1h, suction filter, wash with water until neutral; the residue after suction filtration Add 30 mL of water and boil for...

Embodiment 2

[0030] A process for extracting and purifying oleanolic acid and ursolic acid from sweet tea, comprising the steps of:

[0031] (1) Take a sweet tea sample and crush it with a masher, weigh 150g of the sample, add 3 times the weight of absolute ethanol, and extract it by ultrasonic wave at 35°C for 15min, then filter the extract with suction, and then wash the filtered tea with 300mL ethanol The residue was filtered once again with suction, the suction filtrate was combined with the extract for the first time, the combined extract was concentrated to obtain an extract, the obtained extract was dissolved in 30 mL of chloroform, and the brown extract was obtained after concentration and recovery of chloroform;

[0032] (2) Add 30mL of 5% sodium hydroxide solution to the obtained extract, boil for 10min, suction filter while it is hot, put the filtrate in the refrigerator at 5-10℃ for 1h, suction filter, wash with water until neutral; the residue after suction filtration Add 30 m...

Embodiment 3

[0036] A process for extracting and purifying oleanolic acid and ursolic acid from sweet tea, comprising the steps of:

[0037](1) Take a sweet tea sample and mash it with a masher, weigh 150g of the sample, add 4 times the weight of absolute ethanol, extract it ultrasonically at 40°C for 20min, filter the extract, and wash the filtered tea with 300mL ethanol Residue 1 time, then suction filtration, the suction filtrate is combined with the extract for the first time, and the combined extract is concentrated to obtain an extract, the obtained extract is dissolved in 30mL of chloroform, and the brown extract is obtained after concentration and recovery of chloroform;

[0038] (2) Add 30mL of 5% sodium hydroxide solution to the obtained extract, boil for 10min, suction filter while it is hot, put the filtrate in the refrigerator at 5-10℃ for 1h, suction filter, wash with water until neutral; the residue after suction filtration Add 30 mL of water, heat and boil for 10 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com