Sludge superficial layer curing agent solidification continuous construction method

A construction method and curing agent technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of long processing period, foundation bearing strength not meeting the design requirements, low technical comparability, etc., and achieve flexible and simple construction cost effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

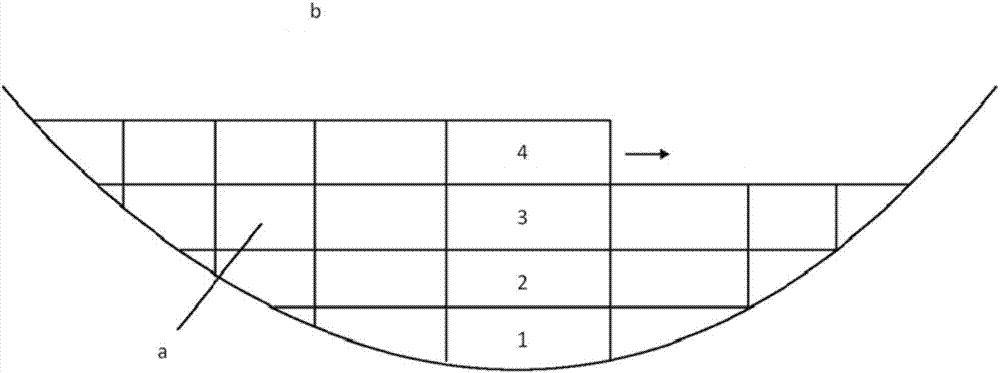

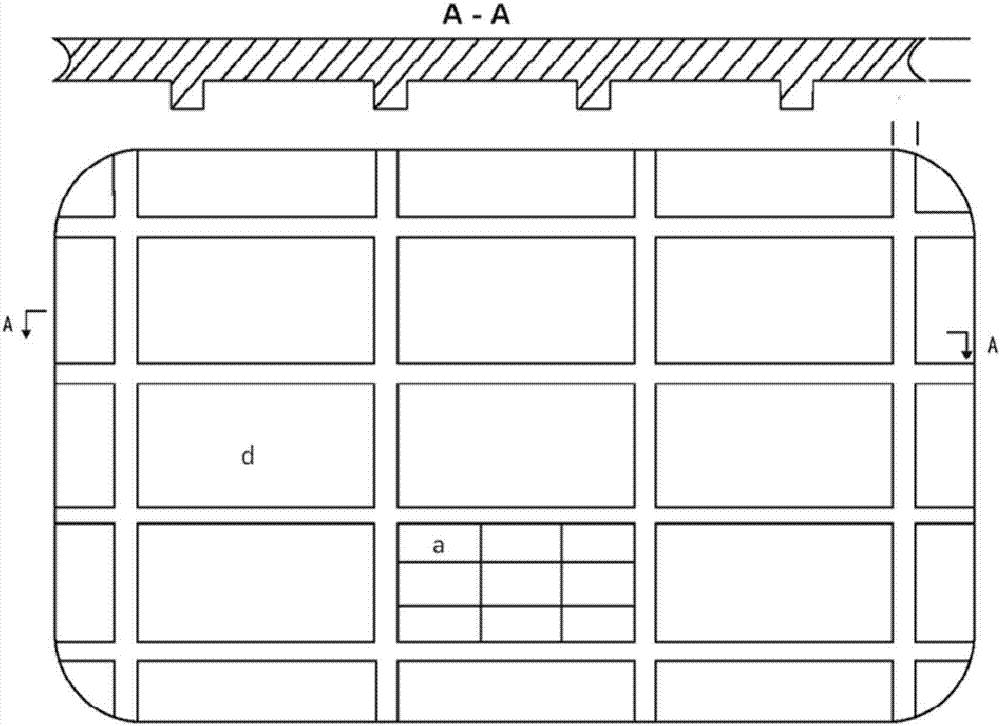

Embodiment 1

[0055] The subgrade construction of Shuichang Road in Caofeidian Development Zone, Hebei Province adopts the continuous construction technology of curing agent shallow surface layer consolidation. The subgrade is 40 meters wide and 1,000 meters long, and the depth of the solidified layer is required to be 1.5 meters. The soft foundation is composed of powder and fine sand mixed with some silt, with a saturated water content of 24%, fine-grained soil accounting for 35%, and a wet density of 1.87g / cm 3 . Add 10% of the curing agent in Example 10 of the invention patent CN101684038A; use the bucket of an ordinary excavator to stir the sludge and the curing agent; The construction surface is used as the operation platform, and the adjacent areas are continued to be treated in the same way according to the block-by-block well-shaped construction method. On-site testing of the unconfined compressive strength of the solidified soil soaked in water for 7 days is greater than 0.8Mpa, ...

Embodiment 2

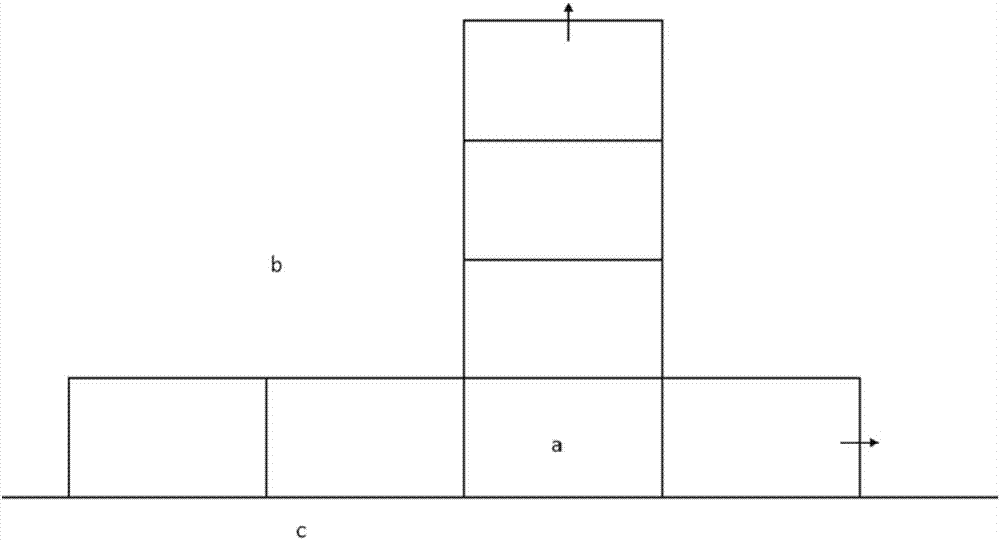

[0057] The subgrade and green area of Dongdi Road in Tianjin Sino-Singapore Eco-city adopt the continuous construction technology of curing agent shallow surface layer consolidation. The soft foundation in this area is dredged fill soil that has been placed for 1.5 years, and the silt layer is 11 meters deep. The project volume is large and the treatment is complicated. Among them: the subgrade is 18 meters wide and 3,800 meters long, curved, and the consolidated soil thickness is 1.5 meters; the green belt area is 130 meters wide and 3,400 meters long, and the required consolidation thickness is 1 meter. In the soft foundation, deep foundation pit pipe trench construction is also required, the deepest depth is 5.5 meters, and it is constructed with solidified soil. The construction is completed by the excavator equipped with a long-axis screw propeller mixing head.

[0058] Get the silt with moisture content of 65-90%, carry out the experiment of adding amount and unconfined...

Embodiment 3

[0064] Shallow surface solidification agent consolidation technology is adopted for the silt soft foundation of Jiaojiang Eleven Pond, Taizhou City, Zhejiang Province. The treatment area is 200×200 meters, the consolidation depth is 1.5 meters, the silt deposit layer is 9 meters deep, the moisture content is 55%, and the wet density is 1.68g / cm 3 .

[0065] The curing agent in Example 9 of the invention patent CN101684038A is mixed with 10%, and the excavator bucket is equipped with a short-axis screw agitator for stirring and compacting, and the construction method of block-by-block construction is continued to remove the sludge in the adjacent area. Do the same. After 14 days, through the shallow plate load test, the characteristic value of the bearing capacity is 150-220Kpa, the deflection value of the deflection test is not greater than 26.8×0.01mm, and the unconfined compressive strength of the site sampling test is greater than 1.14Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com