Novel coke oven smoke waste heat recycling device

A technology of a flue gas waste heat and recovery device, which is applied in the field of coal coking, can solve the problems of high recovery cost, low utilization value, temperature fluctuation, etc., and achieves the effects of low environmental protection maintenance cost, simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

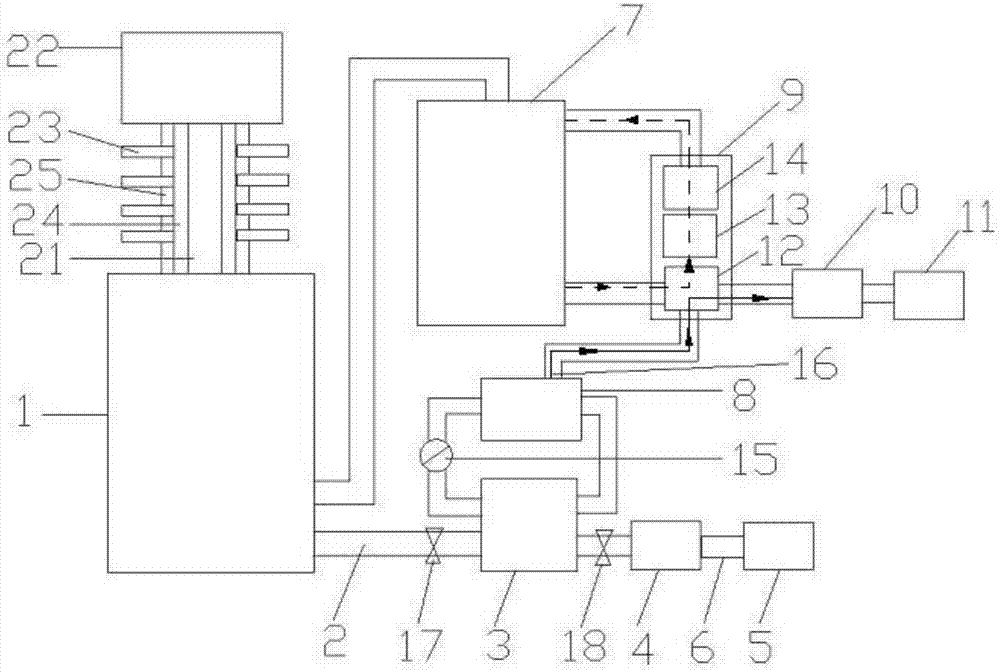

[0016] Such as figure 1 As shown, a new coke oven flue gas waste heat recovery device includes a coke oven 1, a flue 2 is arranged on the coke oven 1, and a waste flue gas waste heat recovery device 3, a thermoacoustic engine 4, and a thermoacoustic refrigerator 5 and the resonant tube 6 connected between the thermoacoustic engine 4 and the thermoacoustic refrigerator 5, the flue 2 of the coke oven 1 communicates with the air inlet of the waste flue gas waste heat recovery device 3, and the waste flue gas The air outlet of the waste heat recovery device 3 is connected with the thermoacoustic engine 4, and the thermoacoustic engine 4, the thermoacoustic refrigerator 5 and the resonance tube 6 are all existing technologies, and the thermoacoustic engine 4 drives the thermoacoustic refrigerator 5 to refrigerate , the thermoacoustic engine 4 is, for example, a traveling wave thermoacoustic engine, and the thermoacoustic refrigerator 5 is, for example, a traveling wave thermoacoust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com