Three-dimensional surface topography measurement method and system based on optical microscopy

An optical microscope and three-dimensional surface technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the detection accuracy is greatly affected, the surface texture and color information cannot be obtained, and corrosion, burns, oxidation, deterioration, etc. cannot be detected. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

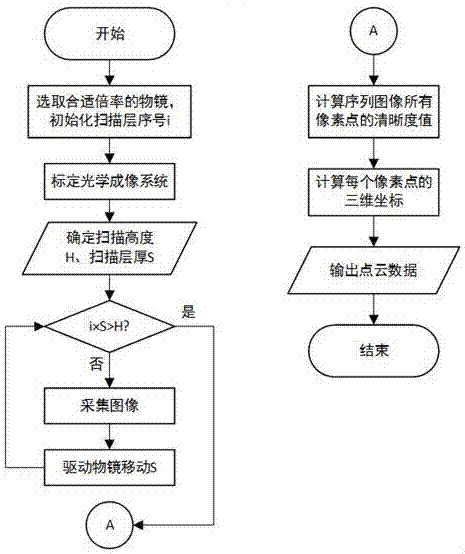

[0030] A three-dimensional surface topography measurement method based on optical microscopy, the flow chart of the embodiment is as follows figure 2 shown, including:

[0031] S1. Select an objective lens with a suitable magnification according to the requirements of lateral resolution and field of view, initialize the scanning layer number i, and select the lighting system with the best effect according to the measured surface condition; calibrate the optical imaging system, and obtain the corresponding pixel pitch on the CCD sensor Determine the height H of the surface to be measured, select the scanning layer thickness S according to the longitudinal resolution, and start scanning when the product of the layer number and the layer thickness is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com