A Water-Helium Cooled Ceramic Breeder Cladding for a Fusion Reactor

A breeding agent and cladding technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems of increased safety hazards, poor cooling performance of helium, and reduced tritium breeding capacity in the breeding area, so as to improve the uniformity of distribution performance, improve the surface heat flow bearing capacity, and reduce the effect of distribution header stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

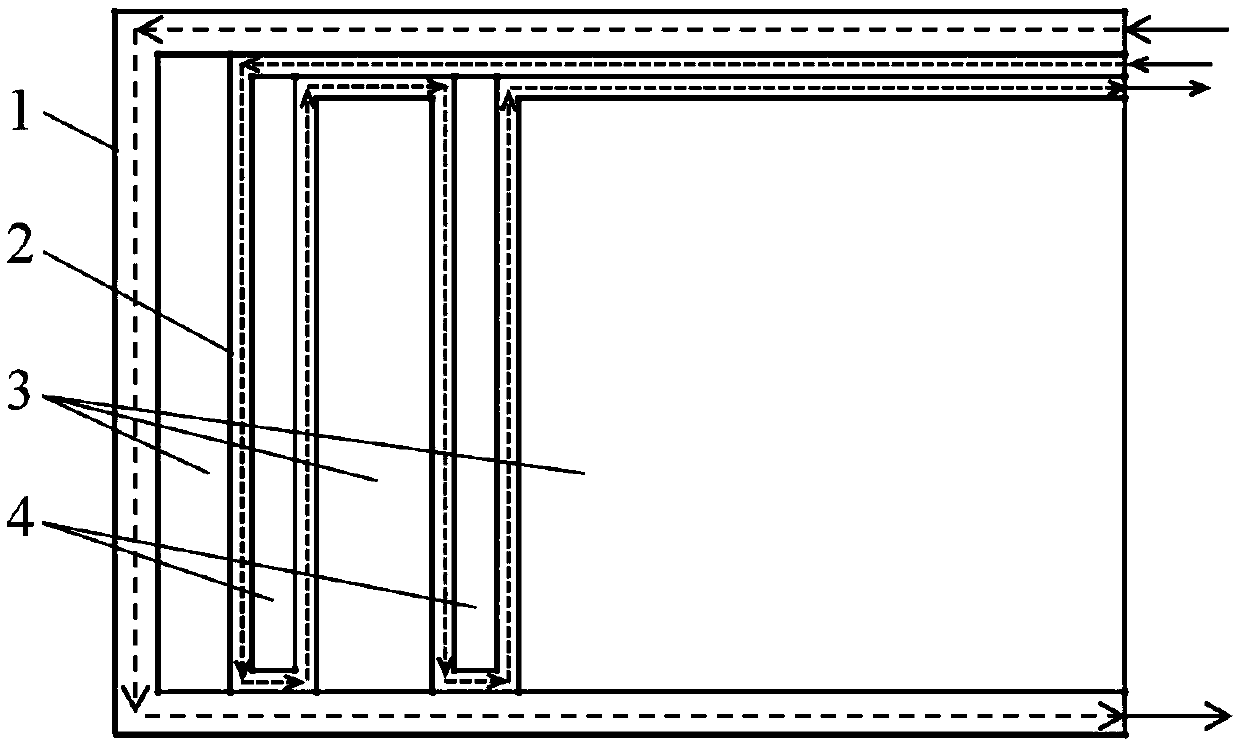

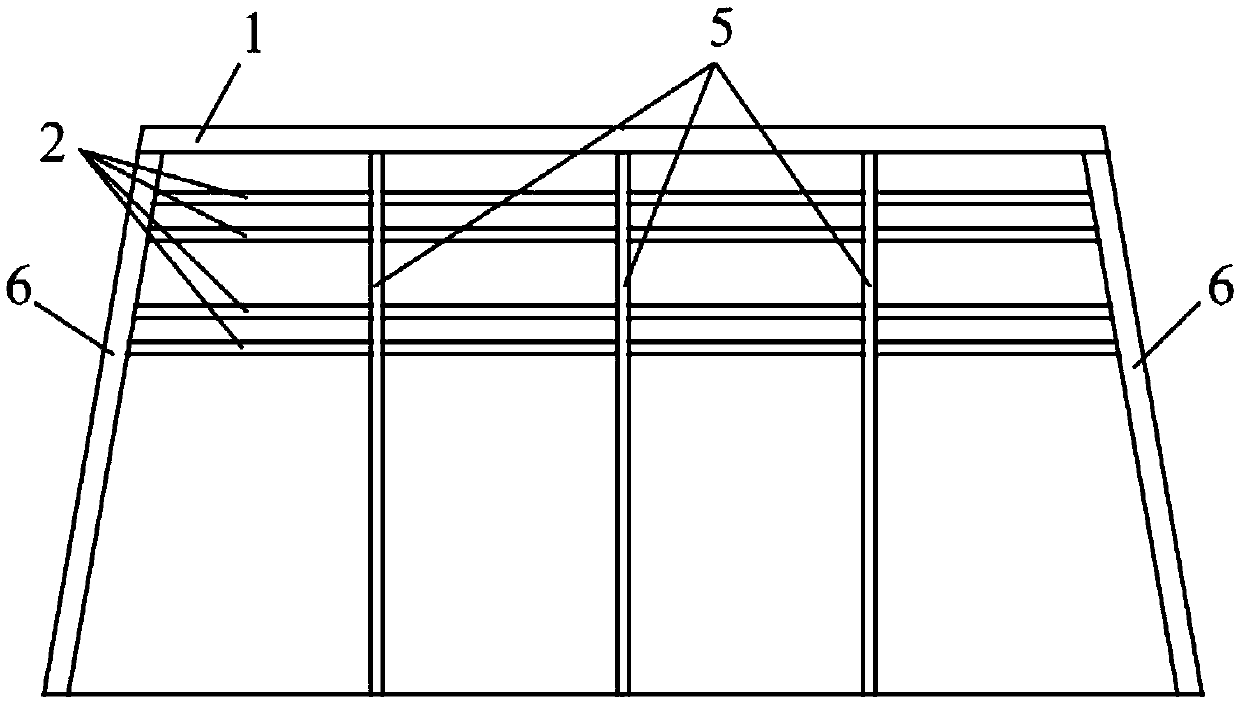

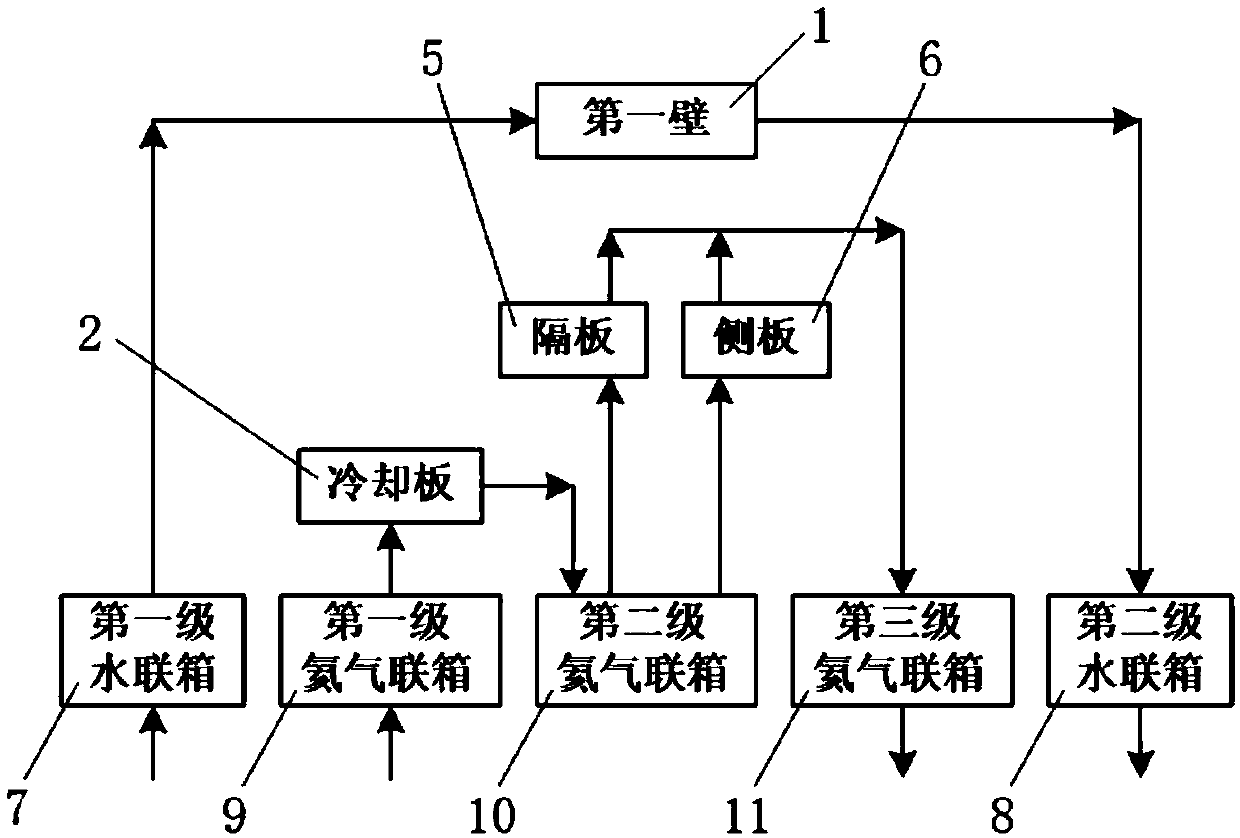

[0018] Such as figure 1 and figure 2 The schematic diagrams of the radial-polar and annular-radial cross-sectional structures of the water-helium-cooled ceramic breeder cladding of the fusion reactor are shown respectively, and the specific structures of the cladding backplate, header structure and coolant flow channel are not shown in the figure. A fusion reactor water-helium cooled ceramic multiplier cladding, comprising a first wall 1, a cooling plate 2, a partition 5 and a side plate 6, the inside of the first wall 1, the cooling plate 2, the partition 5, and the side plate 6 A cooling channel is provided, and water and helium are used as coolants at the same time, water is used to cool the first wall 1, and helium is used to cool the cooling components other than the first wall 1, including the cooling plate 2, the partition plate 5 and the side plate 6. The first wall 1 is a U-shaped plate, and the cooling plate 2 is a concave-shaped plate. The cooling plate 2 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com