Solar battery texturing device

A technology of solar cells and equipment, applied in the field of solar cells, can solve problems such as short service life, inconvenient dust removal, easy to be contaminated with dust, etc., and achieve the effects of improving service life, facilitating heat dissipation, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

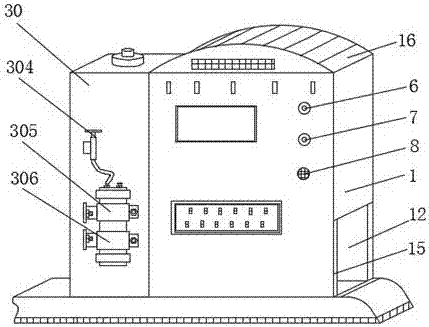

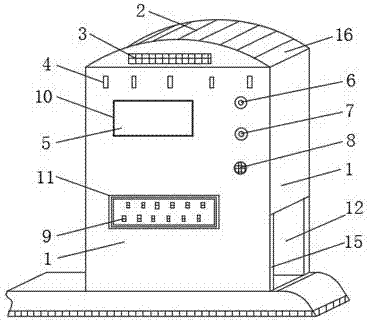

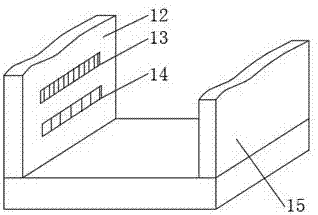

[0029] Example: such as Figure 1-11 As shown, the present invention provides a kind of solar cell texturing equipment, which includes a detection box casing 1, a dust cover 2, a heat dissipation window 3, an LED lighting lamp 4, a display screen 5, a humidity warning lamp 6, a temperature warning lamp 7, a bee Sounder 8, control panel 9, waterproof rubber ring 10, conductive fiber ring 11, first support plate 12, first temperature sensor 13, humidity sensor 14, second support plate 15, first air outlet 16, air outlet 17, Dustproof net 18, one-way ventilation valve 19, dust suction window 20, second air outlet 21, second temperature sensor 22, cooling fan 23, vacuum cleaner 24, dust storage box 25, fan 26, three-way control valve 27, controller 28 and heat shield 29, the top of the detection box shell 1 is equipped with a dust cover 2, both sides of the dust cover 2 are equipped with heat dissipation windows 3, and the top of the detection box shell 1 side is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com