Hydrophobic sun-screening microcapsule and preparation method thereof

A microcapsule and hydrophobic technology, which is applied in pharmaceutical formulations, cosmetic formulations, cosmetic formulations, etc., can solve the problems of sunscreen microcapsules agglomeration, low stability, uneven distribution, etc., and achieves remarkable sunscreen effect and simple preparation process. , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

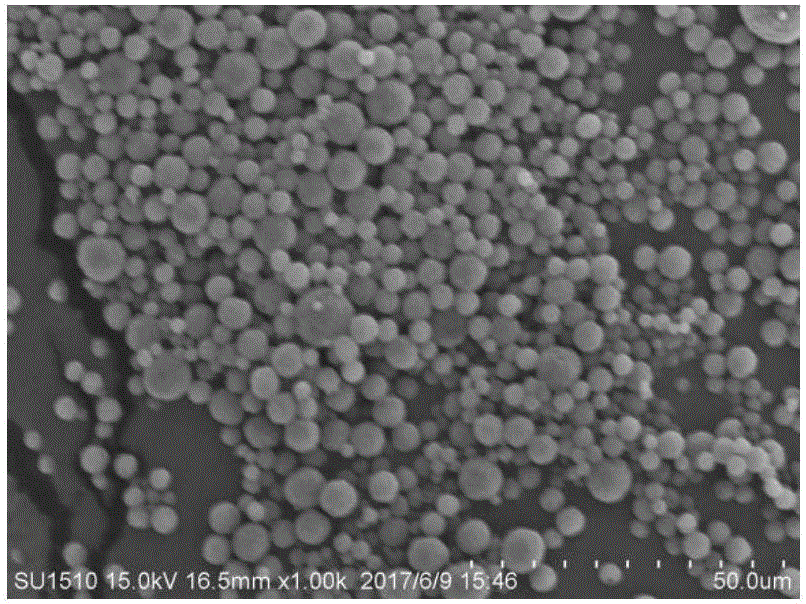

Embodiment 1

[0038] Weigh chitosan with a molecular weight of 5kda and a degree of deacetylation of 90% and place it in a beaker to prepare a 1% chitosan-water solution, add acetic acid to swell and adjust the solution to pH = 3, and set it aside. Weigh gum arabic and sodium caseinate with a mass ratio of 1:1, add water at room temperature and stir to dissolve, and control pH=6. Add 0.4g Tween T-80, stir evenly, then add 0.9g octyl methoxycinnamate, shear at high speed for 5min, control the speed = 10000rpm, and use it as the core material solution. Add the core material solution dropwise to the chitosan solution, control the mass ratio of chitosan: gum arabic: sodium caseinate to 2.5:1:1, control the speed = 400rpm, and control the temperature to 45°C after the dropwise addition is completed. 1h, then lowered to 4°C for 1h reaction, added glutaraldehyde for cross-linking reaction for 1h, and prepared liquid microcapsules. Add liquid microcapsules to 5% glutaraldehyde aqueous solution and...

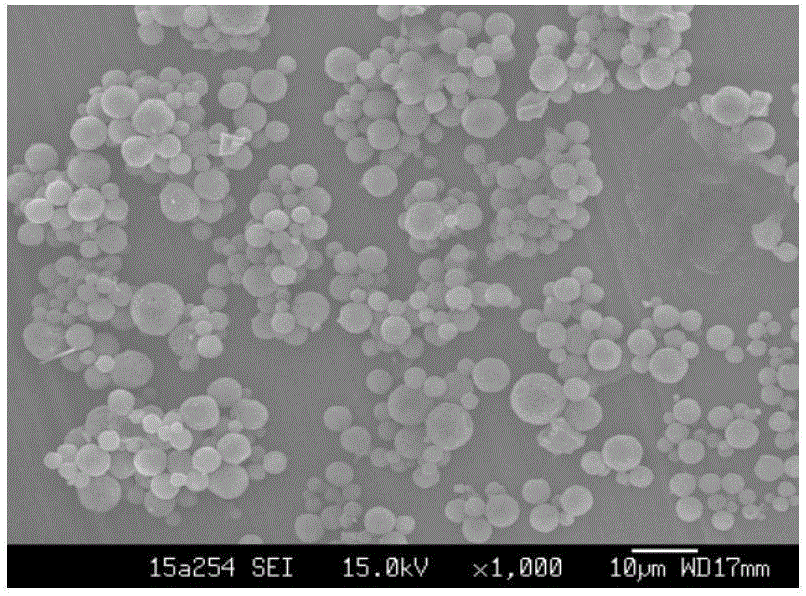

Embodiment 2

[0040] Weigh chitosan with a molecular weight of 5kda and a degree of deacetylation of 90% and place it in a beaker to prepare a 1% chitosan-water solution, add acetic acid for swelling, adjust the pH of the solution to 3.5, and set aside. Weigh Arabic gum and sodium caseinate, the mass ratio is 2:1, add water at room temperature and stir to dissolve, and control pH=6. Add 0.4g Tween T-80, stir evenly, then add 0.9g octyl methoxycinnamate, shear at high speed for 5min, control the speed = 10000rpm, and use it as the core material solution. Add the core material solution dropwise to the chitosan solution, the mass ratio of chitosan: gum arabic: sodium caseinate is 2.5:2:1, control the speed = 250rpm, after the dropwise addition, control the temperature at 45°C for 1h , and then lowered to 4 ° C for 1 h, and then added glutaraldehyde for cross-linking reaction for 1 h to prepare liquid microcapsules. The liquid microcapsules were added into 1% glutaraldehyde aqueous solution an...

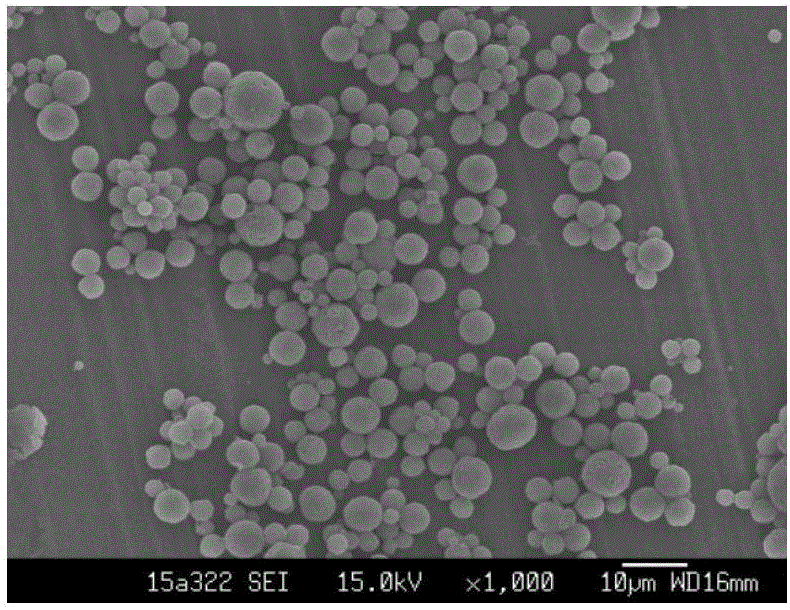

Embodiment 3

[0042] Weigh chitosan with a molecular weight of 5kda and a degree of deacetylation of 90% and place it in a beaker to prepare a 1% chitosan-water solution, add acetic acid to swell and adjust the solution to pH = 3, and set it aside. Weigh gum arabic and sodium caseinate with a mass ratio of 1:1, add water at room temperature and stir to dissolve, and control pH=6. Add 0.4g Tween T-80, stir evenly, then add 0.9g octyl methoxycinnamate, shear at high speed for 5min, control the speed = 10000rpm, and use it as the core material solution. Add the core material solution dropwise to the chitosan solution, the mass ratio of chitosan: gum arabic: sodium caseinate is 1:1:1, control the speed = 400rpm, after the dropwise addition, control the temperature at 40°C for 1h , and then lowered to 8 ° C for 1 hour of reaction, adding glutaraldehyde for cross-linking reaction of 1 hour to prepare liquid microcapsules. The liquid microcapsules were added to 2% glutaraldehyde aqueous solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com