Preparation method of antibacterial composition and antibacterial liquid

The technology of a composition and an acetic acid solution is applied in the directions of drug combinations, medical preparations containing active ingredients, antibacterial drugs, etc., and can solve the problems of poor curative effect, affecting the development prospect and comprehensive utilization of romaine wrinkle, and long treatment period, etc. To achieve rapid treatment, strong antibacterial effect, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

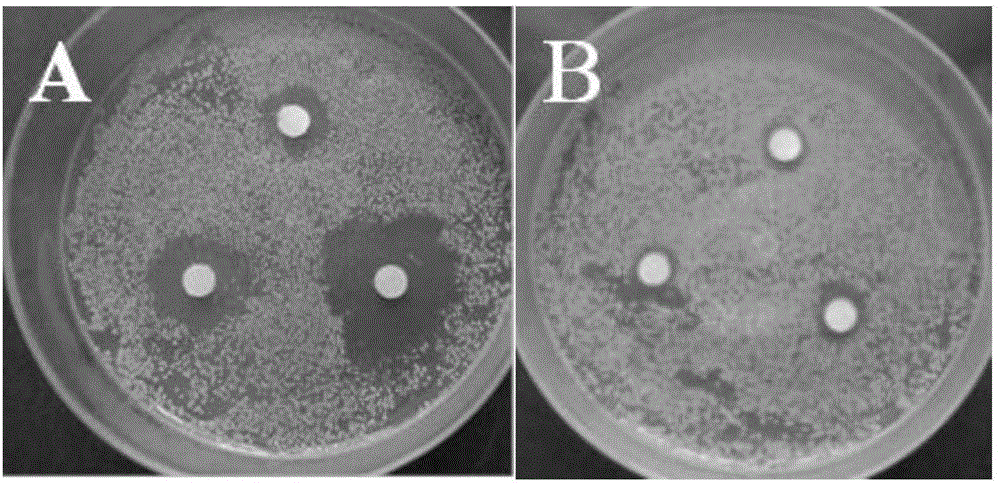

Image

Examples

Embodiment 1

[0035] 1) Take Rumex vulgaris, Polygonum folium, Bletilla striata and Rosemary, wash them with water, cut them into 1.2cm thick slices, and freeze-dry them with a GZL-10 vacuum freeze dryer until the water content is 2%. Use Garman-800Y traditional Chinese medicine pulverizer to pulverize to a particle size of 0.2mm to obtain pulverized raw materials;

[0036] 2) Weigh 102g, 1.0g, 0.5g, and 1.8g of the pulverized raw materials in step 1) successively and put them into non-woven bags, seal them, and soak them in acetic acid whose volume fraction is 20% after 5 times the pulverized raw material volume In the solution, in an environment with a relative humidity of 60%, at 28°C, soak for 70 days to obtain soaked raw materials;

[0037] 3) The soaked raw materials are taken out and dried by centrifugation, and the collected solution is poured back into the container to form the crude antibacterial solution. The crude antibacterial solution is filtered and centrifuged, and the super...

Embodiment 2

[0039] 1) Weigh Rumex wrinkle leaves, Polygonum green leaves, Bletilla striata and rosemary, wash them with clean water, cut into 1.1cm thick slices, and freeze-dry them with a GZL-10 vacuum freeze dryer until the water content is 5%. , using Garman-800Y traditional Chinese medicine pulverizer to pulverize to a particle size of 0.5mm to obtain pulverized raw materials;

[0040] 2) Weigh 100g, 0.8g, 0.5g, and 1.5g of the pulverized raw materials in step 1) successively and put them into non-woven bags, seal them, and soak them into acetic acid whose volume fraction is 25% after 6 times the pulverized raw material volume In the solution, in an environment with a relative humidity of 40%, at 25°C, soak for 60 days to obtain soaked raw materials;

[0041] 3) The soaked raw materials are taken out and dried by centrifugation, and the collected solution is poured back into the container to form the crude antibacterial solution. The crude antibacterial solution is filtered and centri...

Embodiment 3

[0043] 1) Weigh Rumex vulgaris, Folium Polygonum leaves, Bletilla striata and rosemary, wash them with clean water, cut into 1cm thick slices, and freeze-dry them with a GZL-10 vacuum freeze dryer until the water content is 3%. Use Garman-800Y traditional Chinese medicine pulverizer to pulverize to a particle size of 0.3mm to obtain pulverized raw materials;

[0044]2) Weigh 105g, 0.9g, 0.6g, and 1.6g of the pulverized raw materials in step 1) successively and put them into non-woven bags, seal them, and soak them in acetic acid whose volume fraction is 22% after 6 times the pulverized raw materials In the solution, in an environment with a relative humidity of 55%, at 26°C, soak for 65 days to obtain soaked raw materials;

[0045] 3) Take out the raw materials after soaking and spin dry them by centrifugation, collect the solution and pour it back into the container to obtain the crude antibacterial solution, filter and centrifuge the crude antibacterial solution, collect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com