Full-automatic infiltration cleaning line

A cleaning line, fully automatic technology, applied in the field of automatic impregnation cleaning line, can solve problems such as increasing production cost, leakage, and reducing product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

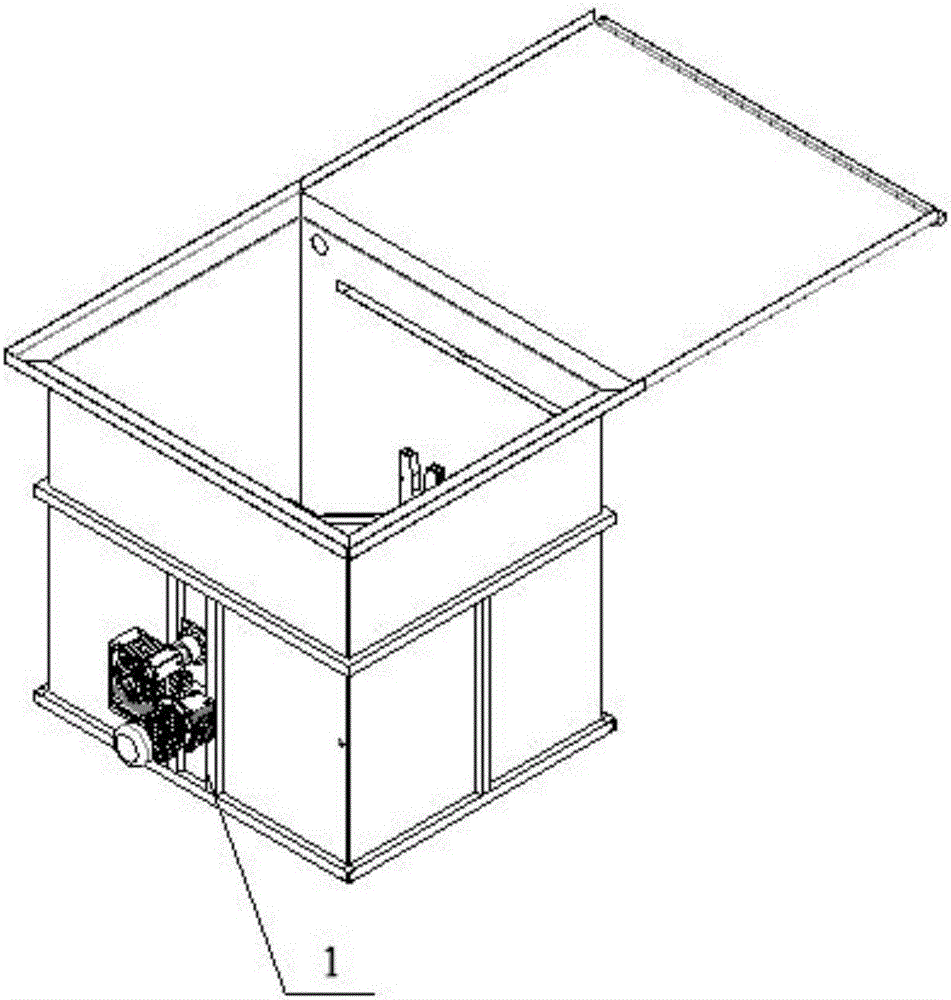

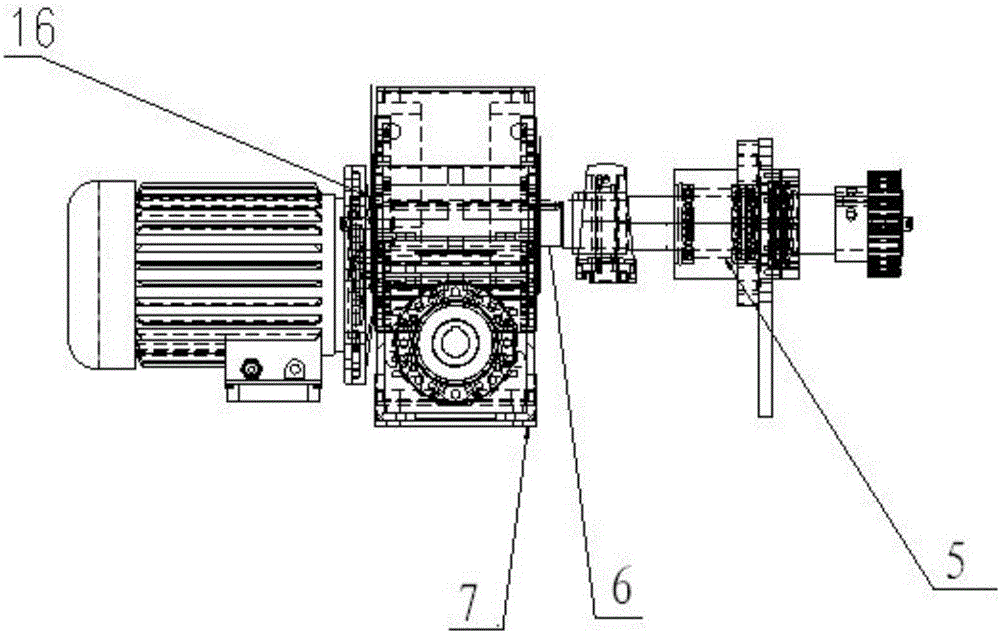

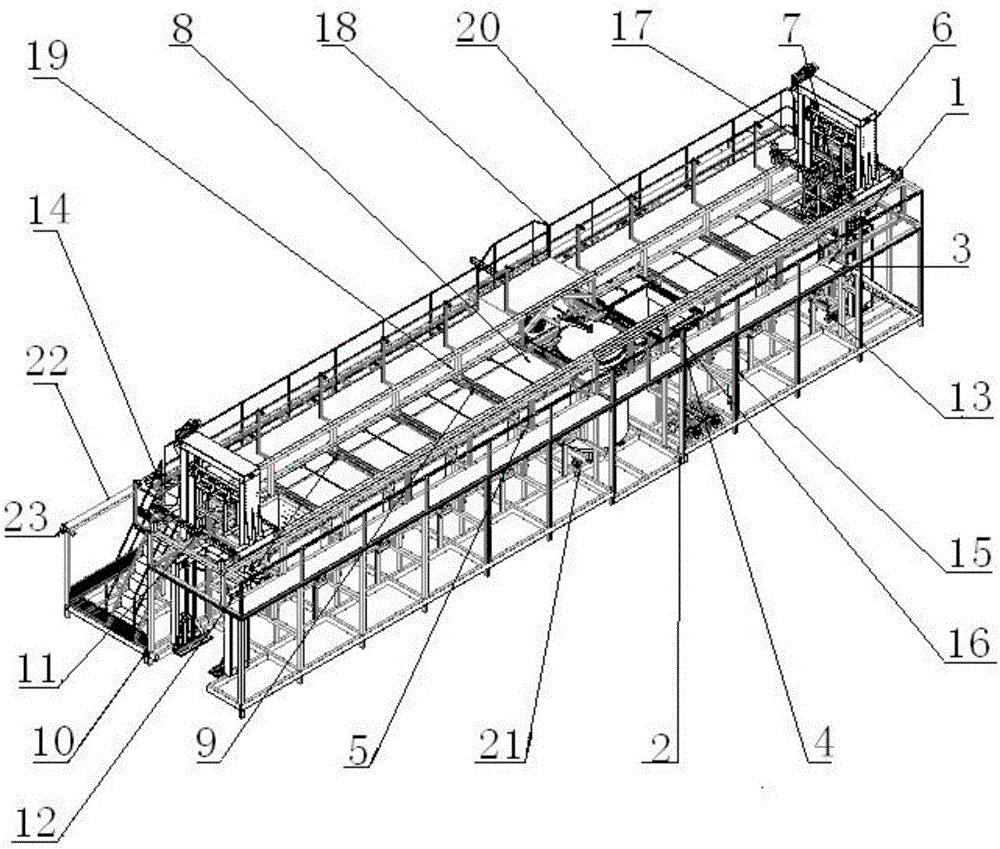

[0157] The technical solution process provided by the present invention is:

[0158] Automatic feeding - ultrasonic cleaning - hot water spray + water blowing - vacuum drying + forced cooling - vacuum pressure impregnation - glue rejection - spray rinsing (1) - spray rinsing (2) - hot water curing - cooling and drying - Automatic discharge

[0159] Design features of the technical solution provided by the present invention:

[0160] The equipment adopts PLC automatic control, and its parameters such as time and temperature can be adjusted on the operation interface.

[0161] A series of advanced production methods, such as inversion cleaning and rinsing, vacuum pressure impregnation and inversion collection, can improve product quality and save production costs.

[0162] The gantry single-arm manipulator is used for handling, which runs stably and provides high-efficiency production.

[0163] Temperature, liquid level and workpiece position are automatically sensed, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com