Low-temperature linseed oil cold-pressing method

A linseed oil and low temperature technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of low utilization rate of linseed, high cost of linseed oil, low oil yield, etc., so as to improve the oil yield and precipitation rate of pressing , Improve the effect of oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

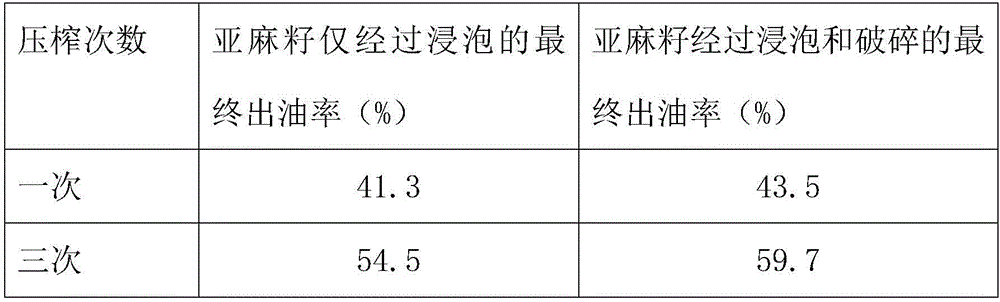

Embodiment 1

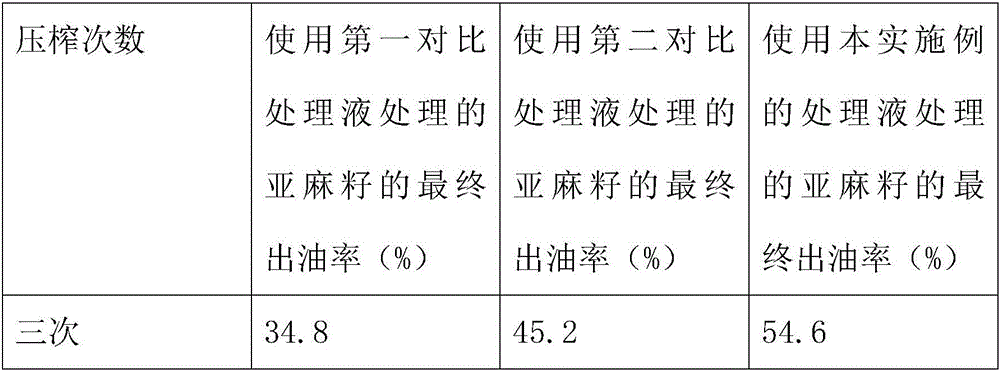

[0020] A low-temperature cold pressing method for linseed oil is characterized in that it comprises the following steps:

[0021] A, put the linseed into the treatment solution and soak for 6h, the treatment solution includes the following components,

[0022] The citric acid of 15wt%, the urea of 7wt%, the tetraethyl ammonium perchlorate of 0.35wt%, the sodium polyacrylate of 2.5wt%, the balance is water;

[0023] B. Rinse the soaked linseed and then dry it;

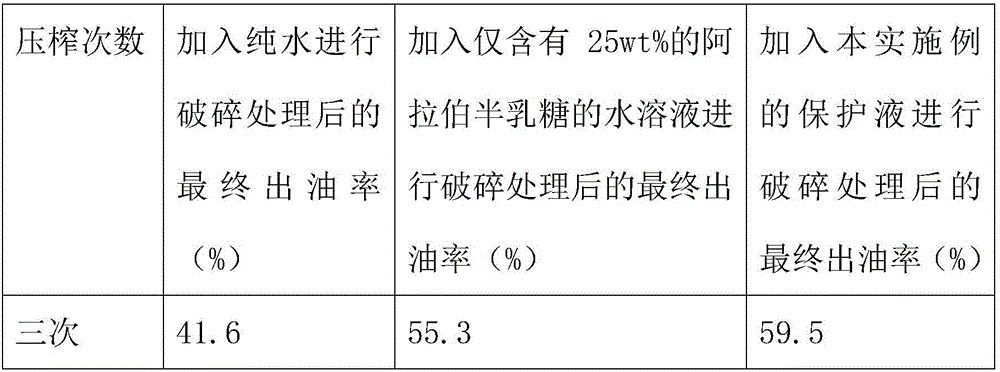

[0024] C. Mix the dried linseed with the protective solution, and then put it into a crusher for crushing. The temperature during the crushing process is controlled at 50°C; the protective solution includes 25wt% arabinogalactose, 10wt% sodium metasulfite and 65wt% of water; the weight ratio of linseed and protective solution is 10:1;

[0025] D, filtering and drying the broken linseed particles;

[0026] E. The linseeds are put into the screw oil press for the first pressing, and the screw speed is 65rad / min;

[...

Embodiment 2

[0044] This embodiment is improved on the basis of Embodiment 1.

[0045] Use the linseed residue discharged in step G, add 2wt% sucrose ester, stir evenly and keep it at 60°C for 8 hours, then extract and refine, and further obtain linseed oil. After the above extraction and refining, the oil yield of linseed can be further improved to around 61%.

[0046] In this embodiment, by adding sucrose ester, the separation degree of oil in linseed residue can be improved, so that more oil can be obtained during re-extraction. In order to verify the effectiveness of the treatment by adding sucrose esters in this example, the linseed residue discharged from step G in the experiment of Example 1 was directly used for extraction and refining, and it was found that compared with the total oil yield before refining, the increase in the total oil yield It is less than 1‰, so direct extraction is ineffective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com