Cleaning agent for cleaning heavy oil stains on range hood, and preparation method of cleaning agent

A range hood and cleaning agent technology, which is applied in the field of cleaning agents, can solve problems such as damage to the paint surface of kitchen range hoods and cabinets, and achieve the effects of good long-term stability, fast removal, good permeability and stripping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

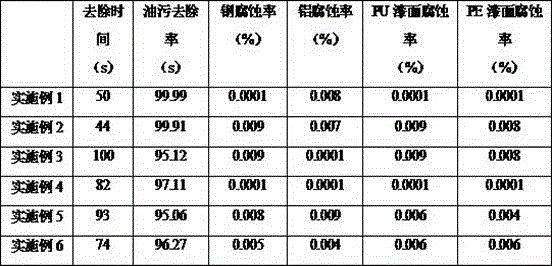

Examples

Embodiment 1

[0017] A cleaning agent for cleaning heavy oil stains in range hoods, which is made of the following raw materials in parts by weight: 5 parts of nano-zeolite powder, 4 parts of nano-alumina fiber, 7 parts of hydroxyethylene diphosphonic acid, and 10 parts of glyceryl stearate 12 parts, 12 parts of polyoxyethylene lauryl ether, 9 parts of cocamidopropyl betaine, 45 parts of water.

[0018] The preparation method, the steps are as follows: Add nano-zeolite powder and nano-alumina fiber into water, disperse at a high speed at 1800r / min, add hydroxyethylene diphosphonic acid and glyceryl stearate, stir for 7 minutes, add laurel Alcohol polyoxyethylene ether, cocamidopropyl betaine, stirred for 8 minutes, that is.

Embodiment 2

[0020] A cleaning agent for cleaning heavy oil stains in range hoods, made of the following raw materials in parts by weight: 6 parts of nano-zeolite powder, 4 parts of nano-aluminum silicate fiber, 8 parts of disodium edetate, glyceryl stearate 12 parts, 10 parts of polyoxyethylene lauryl ether, 12 parts of cocamidopropyl betaine, 46 parts of water.

[0021] The preparation method, the steps are as follows: Add nano-zeolite powder and nano-aluminum silicate fiber into water, perform high-speed dispersion at a speed of 1600r / min, add disodium edetate and glyceryl stearate, stir for 5 minutes, add Lauryl alcohol polyoxyethylene ether, cocamidopropyl betaine, stirred for 10 minutes, that is.

Embodiment 3

[0023] A cleaning agent for cleaning heavy oil stains in range hoods, which is made of the following raw materials in parts by weight: 3 parts of nano-zeolite powder, 5 parts of nano-aluminum silicate fiber, 5 parts of hydroxyethylene diphosphonic acid, and glyceryl stearate 15 parts, 7 parts of polyoxyethylene lauryl ether, 15 parts of cocamidopropyl betaine, 40 parts of water.

[0024] The preparation method, the steps are as follows: Add nano-zeolite powder and nano-aluminum silicate fiber into water, perform high-speed dispersion at a speed of 2000r / min, add hydroxyethylene diphosphonic acid and glyceryl stearate, stir for 5 minutes, add Lauryl alcohol polyoxyethylene ether, cocamidopropyl betaine, stirring for 5 minutes, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com