Fluorine-modified silicon rubber with protein non-specific adsorption resistance, preparation method and applications thereof

A non-specific, silicone rubber technology, applied in the field of surface modification of biomedical materials, can solve the problems of electrode conductivity isolation, loss of effectiveness, protein adhesion, etc., to achieve increased thickness, long action time, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

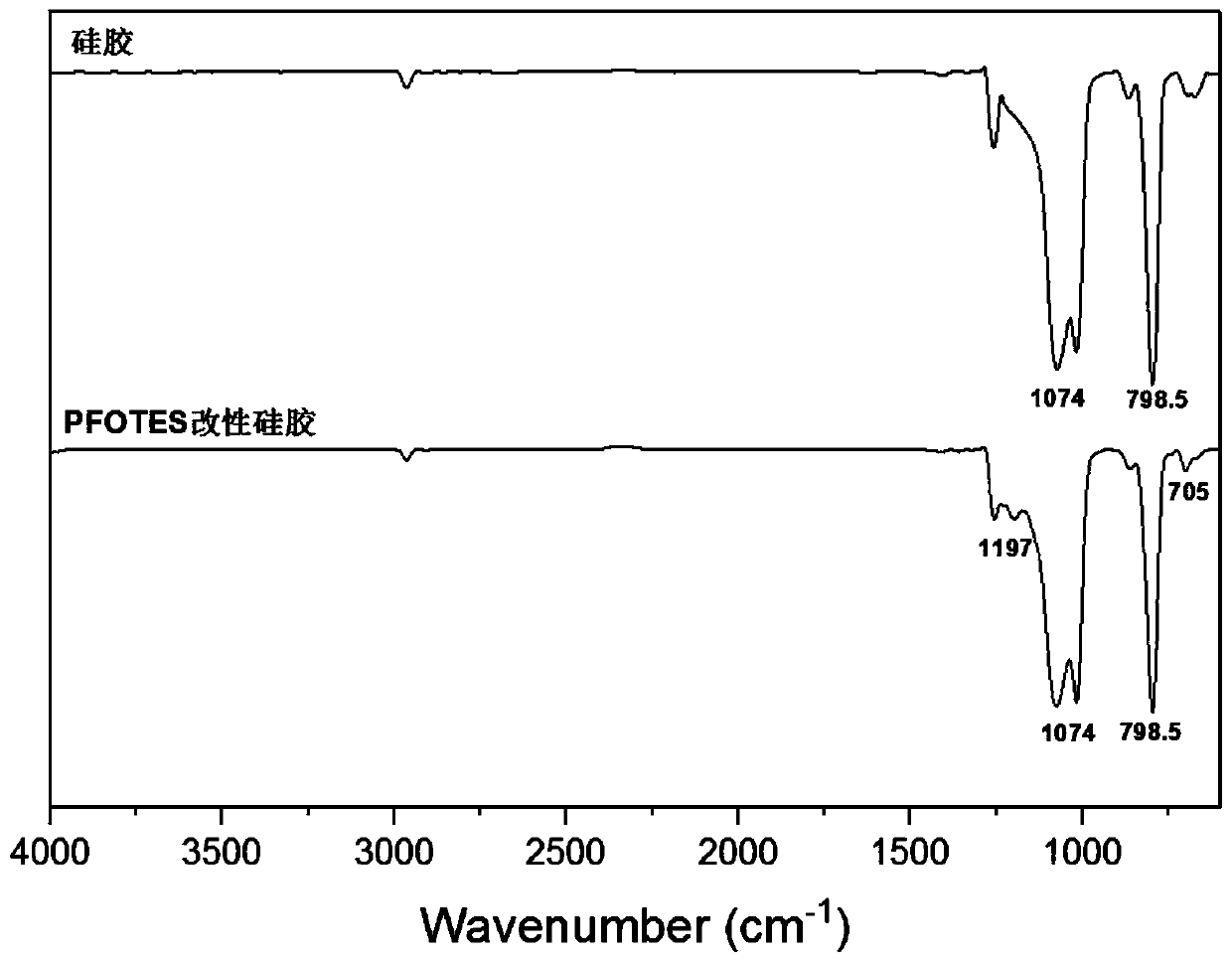

Method used

Image

Examples

Embodiment 1

[0048]Put a 10cm×10cm×1mm silicone rubber sheet in a 1L beaker and ultrasonically clean it with deionized water, then dry it at a vacuum of 10KPa and a temperature of 129°C for 24h, and clean the surface of the silicone rubber under 110W UV light for 20 minutes , to remove surface oxides and other contaminants. Immediately after ozone treatment, immerse the silicone rubber sheet in deionized water and incubate in an oven at 80°C for 24 hours, then dry it in nitrogen, vacuum at 50KPa, and temperature at 25°C for 24h, and store it in a sealed container; at room temperature, it is calculated by volume percentage 5% Tridecafluorooctyltriethoxysilane (PFOTES) and 81% methanol, 14% mass fraction of 36% acetic acid aqueous solution are added to a dry petri dish, the total volume of the mixed solution is 20ml; Clean the silicon rubber sheet (10cm×10cm×1mm), seal the petri dish with plastic wrap, put it in a vacuum drying oven, vacuumize it for about 15min (vacuum degree is 50KPa), and...

Embodiment 2

[0050] The silicone rubber modified with tridecafluorooctyltriethoxysilane obtained in Example 1 was washed 3 times with deionized water, soaked in PBS buffer solution (pH=7.4) for 60 min, N 2 Blow dry; Petri dish is rinsed 3 times with PBS damping fluid (pH=7.4); Bovine serum albumin is mixed with the PBS buffering fluid of pH=7.4 to be the BSA solution that concentration is 5mg / L; Then BSA solution is added into petri dish, Add tridecafluorooctyltriethoxysilane-modified silicone rubber (completely submerged in BSA solution), soak at room temperature for 24 hours, take out the silicone rubber after the reaction, wash it with PBS buffer solution for 3 times, and then wash it with deionized water for 3 times. then use N 2 Blow dry, and finally observe the fluorescence under a fluorescence microscope.

Embodiment 3

[0052] Rinse the unmodified silicone rubber and PFOTES-modified silicone rubber in Example 1 once with appropriate amount of distilled water, blow dry with nitrogen, and incubate in 20mL of 37°C physiological saline for 0.5h, then modify the silicone rubber and PFOTES Place the silicone rubber in an ultra-clean bench for ultraviolet sterilization, and then add it to a 24-well cell culture plate (the size of the silicone rubber or modified silicone rubber in each well is 0.5cm×0.5cm×1mm), and add 500μL DMEM to each well Complete medium (DMEM basal culture plus 5% fetal bovine serum (brand Gibco, product number A3160802) and 1% double antibody (brand Gibco, product number 15140-122, wherein double antibody components: each milliliter double antibody contains 10000units penicillin and 10000μg streptomycin) in 5% CO 2 Equilibrate in a 37°C incubator for 24 hours. Aspirate the medium, add 500 μL of mouse fibroblast (L929) cell suspension (the medium is DMEM complete medium), in wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com