Gas turbine variable-back-pressure transformation system for combined cycle power station

A gas turbine and combined cycle technology, which is applied in the direction of combined combustion mitigation, turbine/propellant fuel delivery system, charging system, etc., can solve the problems of not being able to make full use of IGV regulation and low thermal efficiency, and achieve convenient maintenance, improved operation economy, The effect of improving turbine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a gas turbine combined cycle variable back pressure modification system. The following description is given in conjunction with the drawings and examples.

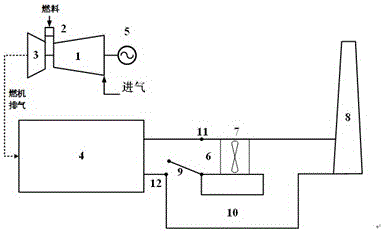

[0020] Such as figure 1 In the schematic diagram of the gas turbine variable back pressure retrofit system shown, the system mainly includes compressor, combustion chamber, gas turbine, waste heat boiler, induced draft fan flue, induced draft fan, induced draft fan bypass flue, and flue gas bypass baffle And chimneys and other devices; characterized in that: the air is compressed by the compressor (1) and then enters the combustion chamber (2), the flue gas after the fuel is burned in the combustion chamber enters the gas turbine (3), and the high-temperature flue gas expands in the turbine After construction, the waste heat boiler (4) is passed into the waste heat boiler. The outlet flue gas channels of the waste heat boiler are respectively set as the induced draft fan flue (6) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com