Scale amount measurement system and method for superheater tube sample of thermal power plant

A superheater tube and measurement system technology, applied in the direction of material electrochemical variables, boiler working status indication, boiler cleaning device, etc., can solve the problem of difficult superheater tube removal, increased matrix metal corrosion loss, and low measurement results And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

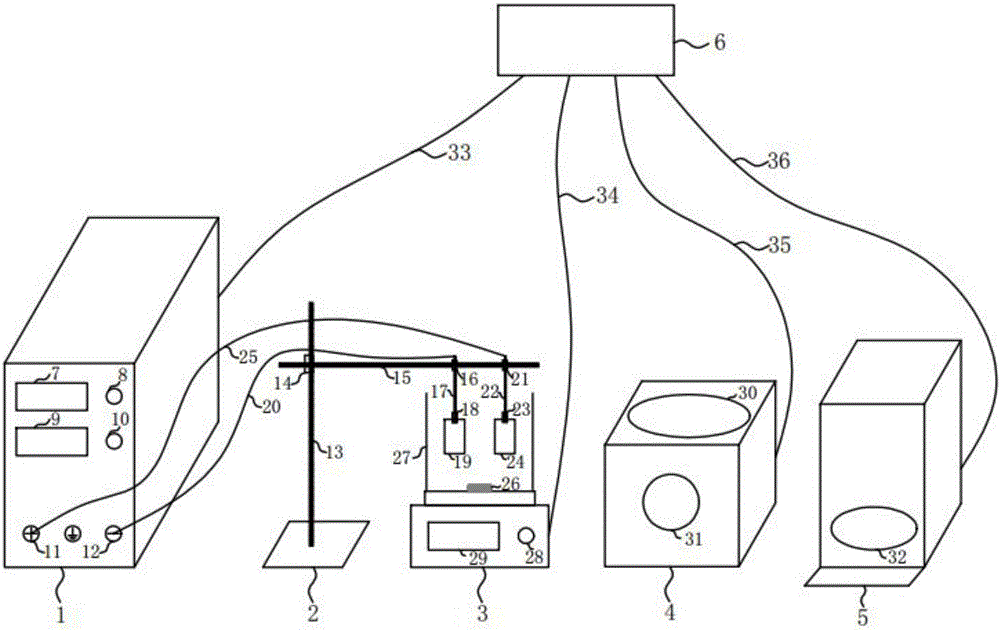

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] ginseng figure 1 As shown, the present embodiment provides a thermal power plant superheater tube sample scale measurement system, including: DC electrolysis instrument 1, experimental support 2, magnetic stirring electrolytic cell 3, ultrasonic cleaner 4 and electronic devices with a precision of 1 / 10,000. Balance 5 and AC 220V 50Hz power supply 6.

[0026] The DC electrolysis instrument 1 includes: a DC voltage display screen 7 , a DC voltage adjustment knob 8 , a current density display screen 9 , a current density adjustment knob 10 , a positive electrode 11 of the electrolysis instrument, and a negative electrode 12 of the electrolysis instrument.

[0027] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com