Black pigment composition and black coating film formation composition including the black pigment composition

A black pigment and composition technology, applied in the field of black pigment composition and black coating film forming composition containing it, and black coating film forming composition, can solve problems such as irregularity, large gap distance deviation, light leakage, etc. Achieves the effect of inhibiting absorption and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

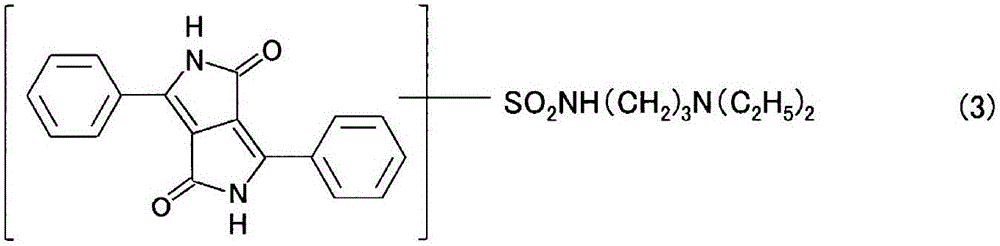

[0162] (Production Example 1) Production of Pigment Derivative 1

[0163] With respect to 200 parts by weight of chlorosulfonic acid, pigment red 255 (manufactured by BASF Corporation, product name Irgazin Red L3551HD) was added so that 20 parts by weight and thionyl chloride became 10 parts by weight, and after reacting at 60° C. for 5 hours, it was discharged to 2 1 liter of ice water, filtered and washed with water to obtain 26.9 parts by weight of the chlorosulfonyl compound of Pigment Red 255. Make it dispersed in 200 parts by weight of water, add 8.3 parts by weight of diethylaminopropylamine, react at 80°C for 1 hour, filter, wash with water, dry and pulverize to obtain 31.5 parts by weight of the following formula (3): Pigment derivative 1 shown.

[0164]

manufacture example 2

[0165] (Production Example 2) Production of Pigment Derivative 2

[0166] Add pigment violet 23 (manufactured by DIC Corporation, product name Violet 23 Crude) to 20.4 parts by weight and thionyl chloride to 20 parts by weight with respect to 200 parts by weight of chlorosulfonic acid, react at 60° C. for 5 hours, and discharge to 2 liters of ice water was filtered and washed with water to obtain 27.2 parts by weight of a chlorosulfonyl compound of Pigment Violet 23. Make it dispersed in 200 parts by weight of water, add 15 parts by weight of diethylaminopropylamine, react at 80°C for 1 hour, filter, wash with water, dry and pulverize to obtain 31.9 parts by weight of the following formula (4): Pigment derivative 2 shown.

[0167]

manufacture example 3

[0168] (Production Example 3) Production of Pigment Derivative 3

[0169] After charging 200 parts by weight of 88% sulfuric acid into a 300 ml three-necked flask, 20 parts by weight of Pigment Red 255 (manufactured by BASF Corporation, product name Irgazin Red L3551HD) was charged under water cooling, and reacted at 40 to 45° C. for 3 hours. Sulfonated. Next, after discharging this synthetic stock solution into a beaker with 1L of water, filter it, transfer the paste to a 2L beaker, add 1.5L of water, and stir at 60-70°C for 1 hour to fully disperse , adding 1 weight part of cetyltrimethylammonium chloride, and performing salt production. After stirring for about 10 minutes, it was filtered and washed with water, and the obtained paste was dried at 100° C. to obtain a pigment derivative 3 represented by the following formula (5).

[0170]

[0171] (DM-3)

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com