Microfluidic system and driving method thereof

A microfluidic system and substrate technology, applied in the field of micro-control, can solve problems such as unfavorable precision, complex fabrication of microfluidic system, signal interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation of the microfluidic system and its driving method provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0048] The shape, size and shape of each component in the drawings do not reflect the real scale, and the purpose is only to schematically illustrate the content of the present invention.

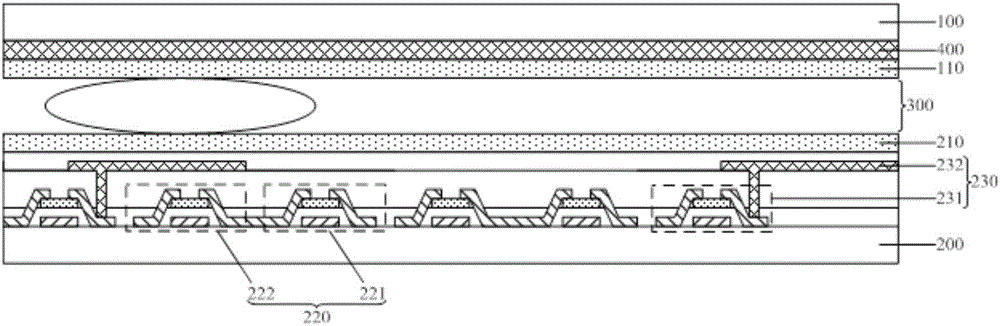

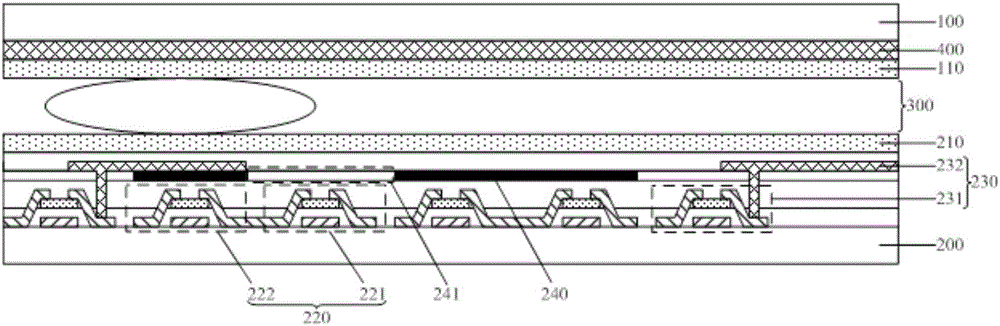

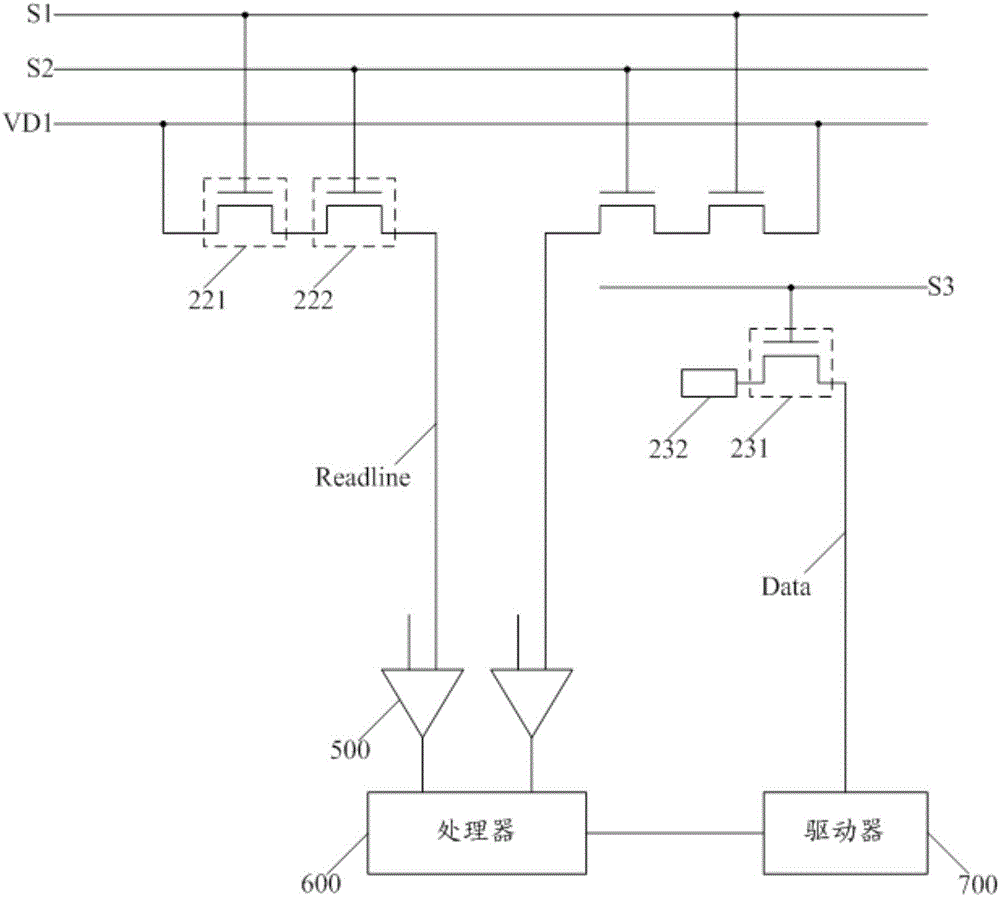

[0049] Therefore, a microfluidic system provided by an embodiment of the present invention, such as Figure 1a shown, including:

[0050] The upper substrate 100 and the lower substrate 200 facing each other form a droplet accommodation space 300 between the upper substrate 100 and the lower substrate 200;

[0051]The first hydrophobic layer 110 located on the outermost surface of the upper substrate 100 facing the droplet accommodation space 300;

[0052] The second hydrophobic layer 210 located on the outermost surface of the lower substrate 200 facing the droplet accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com