Shaping method of foods with stuffing

A food forming and stuffing technology, which is applied in bakery food, dough forming and cutting equipment, food science, etc., can solve the problems of shrinking the volume of stuffed food forming machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

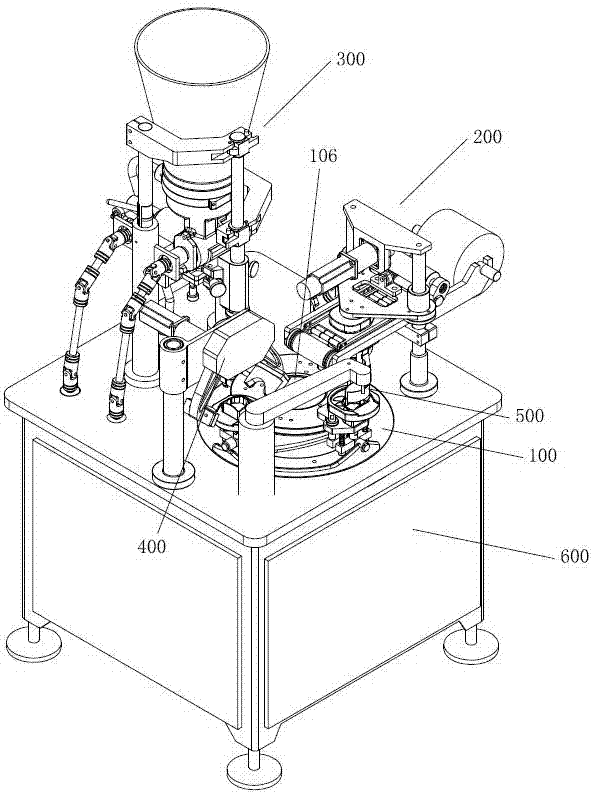

[0129] A method for forming stuffed food, characterized in that: comprising

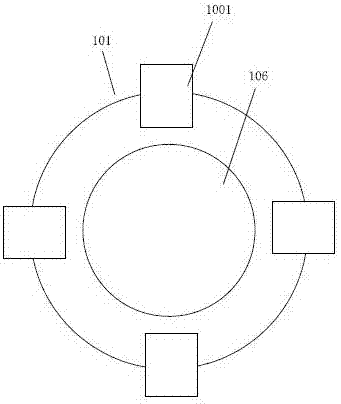

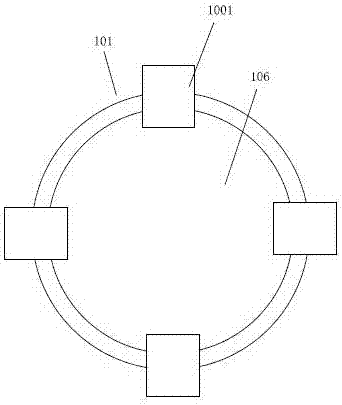

[0130] The first step: send and cut the skin, the forming mold 1001 on the turntable is located below the skin feeding and cutting station 20, the dumpling skin is cut into the dough of the specified shape and falls on the forming mold 1001 below, after the skin is cut The residual skin enters the opening 106 on the turntable and is transmitted downward to realize the recovery of residual skin;

[0131] Step 2: Filling is injected, the turntable drives the forming mold 1001 after the skin is attached to rotate to the filling station 30, and the filling is injected onto the dough.

Embodiment 2

[0133] A method for forming stuffed food, characterized in that: comprising

[0134] The first step: send and cut the skin, the forming mold 1001 on the turntable is located below the skin feeding and cutting station 20, the dumpling skin is cut into the dough of the specified shape and falls on the forming mold 1001 below, after the skin is cut The residual skin enters the opening 106 on the turntable and is transmitted downward to realize the recovery of residual skin;

[0135] Step 2: Filling is injected, the turntable drives the forming mold 1001 after the skin is attached to rotate to the filling station 30, and the filling is injected onto the dough.

[0136] Further, it also includes:

[0137] The third step: pressing and forming, the turntable drives the filling mold 1001 to rotate to the forming station, and presses and forms the dough;

[0138] Step 4: The finished product is taken out, and the turntable drives the formed forming mold 1001 to rotate to the take-out...

Embodiment 3

[0140] A method for forming stuffed food, characterized in that: comprising

[0141] The first step: send and cut the skin, the forming mold 1001 on the turntable is located below the skin feeding and cutting station 20, the dumpling skin is cut into the dough of the specified shape and falls on the forming mold 1001 below, after the skin is cut The residual skin enters the opening 106 on the turntable and is transmitted downward to realize the recovery of residual skin;

[0142] Step 2: Filling is injected, the turntable drives the forming mold 1001 after the skin is attached to rotate to the filling station 30, and the filling is injected onto the dough.

[0143] Further, it can also include:

[0144] The third step: pressing and forming, the turntable drives the filling mold 1001 to rotate to the forming station, and presses and forms the dough;

[0145] Step 4: The finished product is taken out, and the turntable drives the formed forming mold 1001 to rotate to the take-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com