Method for preparing core-shell structured particles and hollow particles by ultrasonic field

A core-shell structure and particle technology is applied in the field of ultrasonic synthesis, which can solve the problems of low synthesis steps and yield limitations, and achieve the effect of controllable shell structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

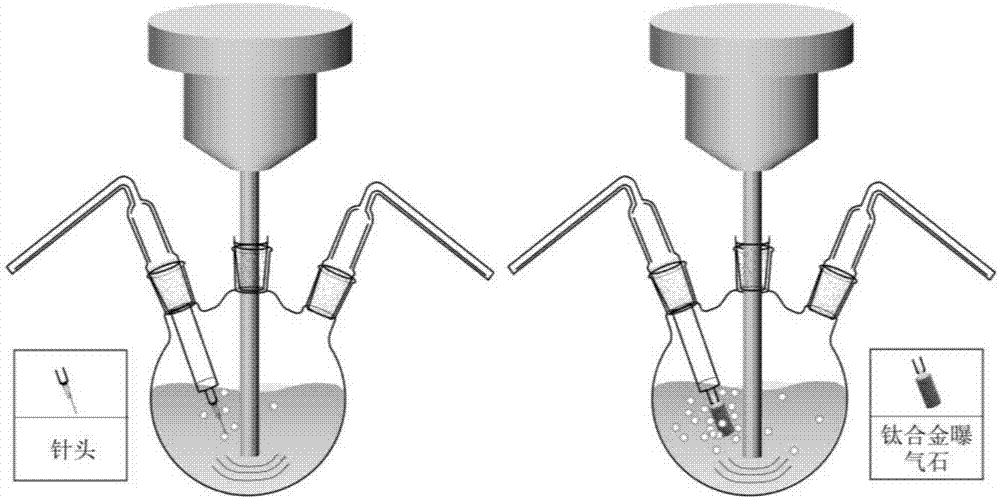

[0029] a)SiO2 2 Activation: Add nano-SiO to a 100ml three-neck flask 2 (hydroxyl content 14%) 1.00g and dispersed in 30ml ethanol solution; using ultrasonic (10min)-intermittent (5min, pass N 2 Air) cycle mode for intermittent ultrasound 30min, ultrasound power 750W;

[0030]b) Three cycles of vacuum: 0.67g of NIPAm monomer and 0.067g of BIS (crosslinking agent) were dissolved in 30ml of deionized water, then added to a three-necked flask and vacuumed three times;

[0031] c) Selection of reaction conditions: inject nitrogen gas through the needle; select ultrasonic power of 750W, and use ultrasonic (10min)-intermittent (5min, pass N) at 25°C 2 Gas) circulation mode for polymerization reaction, the cumulative time of ultrasonic is 2h;

[0032] d) Post-treatment: the product is separated, and separated by centrifugation and changing the liquid three times with ultrapure water. Freeze drying box, low temperature vacuum drying for 24h.

Embodiment 2

[0034] a)SiO2 2 Activation: Add nano-SiO to a 100ml three-neck flask 2 (hydroxyl content 14%) 1.00g and dispersed in 30ml ethanol solution; using ultrasonic (10min)-intermittent (5min, pass N 2 Air) circulation mode for intermittent ultrasound for 30 minutes, the ultrasonic power is 750W, and the ultrasonic power is 750W;

[0035] b) Three cycles of vacuum: 1.00 g of NIPAm monomer and 0.05 g of BIS (crosslinking agent) were dissolved in 30 ml of deionized water, then added to a three-necked flask and vacuumed three times;

[0036] c) Selection of reaction conditions: Nitrogen gas is passed through the needle; the ultrasonic power is 750W, and ultrasonic (10min)-intermittent (5min, N) is used at 25°C 2 Gas) circulation mode for polymerization reaction, ultrasonic irradiation cumulative 2.5h;

[0037] d) Post-treatment: the product is separated, and separated by centrifugation and changing the liquid three times with ultrapure water. Freeze drying box, low temperature vacuum...

Embodiment 3

[0041] a)SiO2 2 Activation: Add nano-SiO to a 100ml three-neck flask 2 (hydroxyl content 14%) 1.00g and dispersed in 30ml ethanol solution; using ultrasonic (10min)-intermittent (5min, pass N 2 Air) circulation mode for intermittent ultrasound for 30 minutes, the ultrasonic power is 750W, and the ultrasonic power is 750W;

[0042] b) Three cycles of vacuum: 1.00g of NIPAm monomer, 0.05g of BIS (crosslinking agent) and 0.10g of NVP monomer were dissolved in 30ml of deionized water, and then added to a three-necked flask to vacuum three times;

[0043] c) Selection of reaction conditions: inject nitrogen gas through the needle; select ultrasonic power of 750W, and use ultrasonic (10min)-intermittent (5min, pass N) at 25°C 2 Gas) circulation mode for polymerization reaction, the cumulative time of ultrasonic is 2h;

[0044] d) Post-treatment: the product is separated, and separated by centrifugation and changing the liquid three times with ultrapure water. Freeze drying box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com