Centrifugal compressor

A technology of centrifugal compressor and diffuser, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems that affect the reliability of compressor operation, the range of cooling is limited, and the overheating loss is serious. Heat flow, reduce the cooling range, and the effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions, and technical effects of the present invention clearer, the following describes specific embodiments of the present invention with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

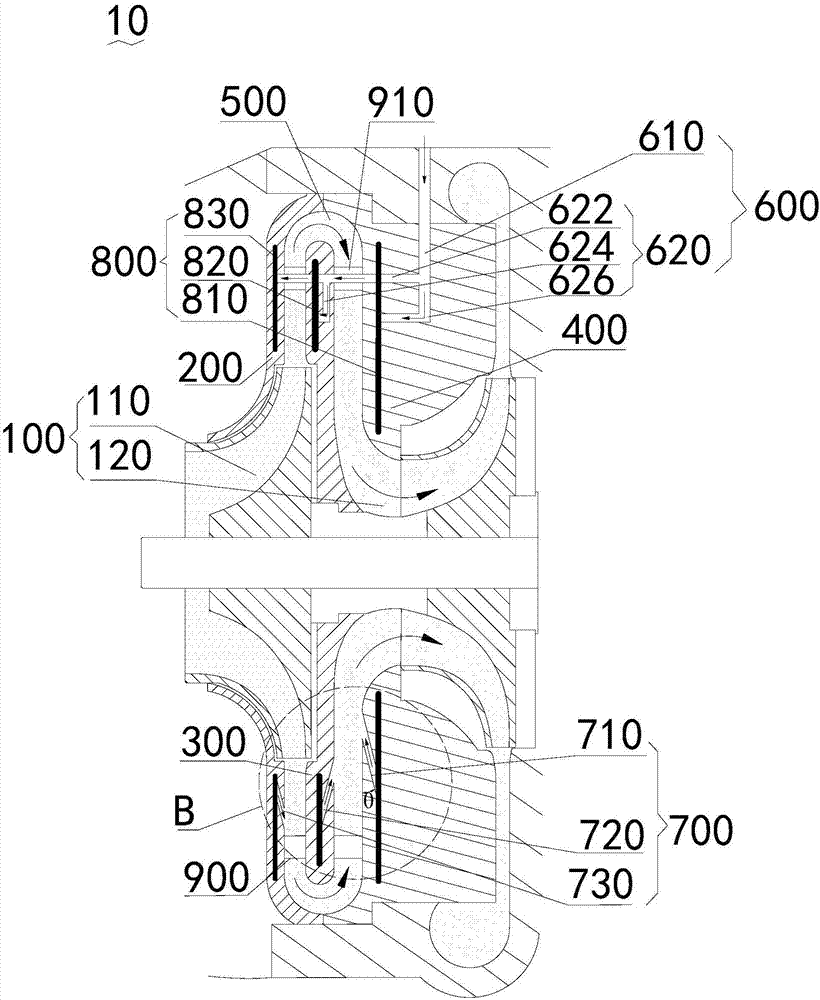

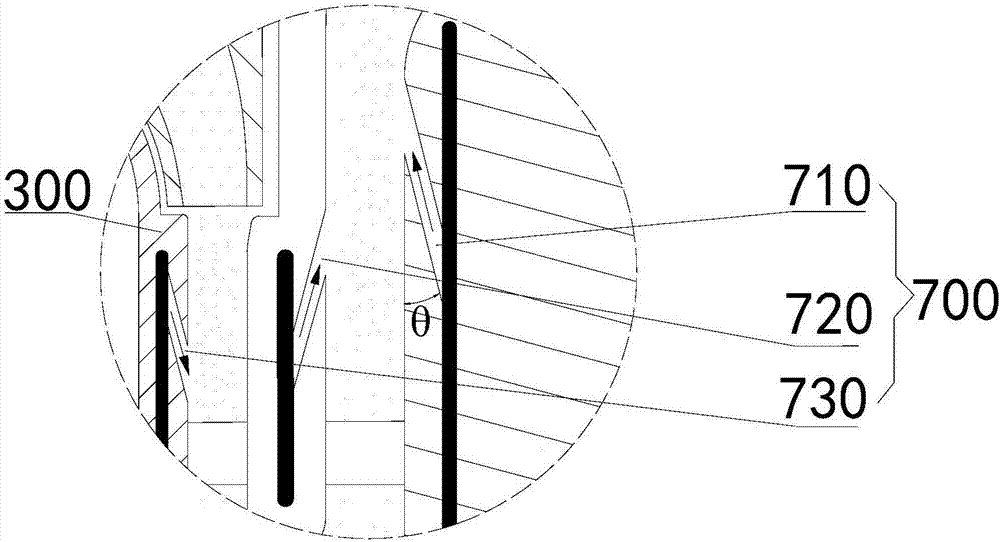

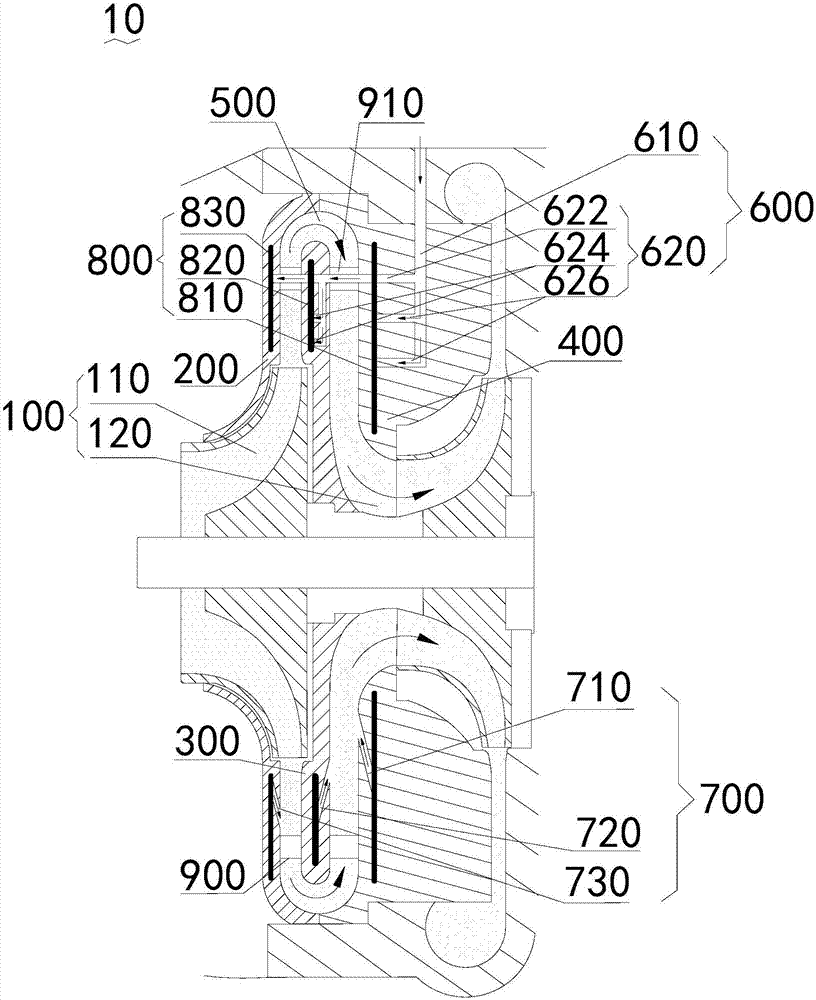

[0034] See figure 1 , The present invention provides a centrifugal compressor 10, which includes at least two stages of impeller 100, a diffuser 200, a return flow plate 300 and a return 400. The diffuser 200, the return flow plate 300 and the return flow device 400 form a stage flow channel 500 connecting the two stages of the impeller 100. The centrifugal compressor 10 also includes a supplemental air passage. The air supplement channel includes an air supplement port 600, an air outlet 700, and a cooling channel 800. The cooling channel 800 is disposed inside at least one of the diffuser 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com