Hot air deicing total pressure sensor

A sensor, hot gas technology, applied in instruments, measuring fluid pressure, measuring devices, etc., can solve the problems of limited efficiency of liquid de-icing system, unsynchronized time and space, increase aircraft weight and power consumption, etc., to improve energy Utilization, light weight, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

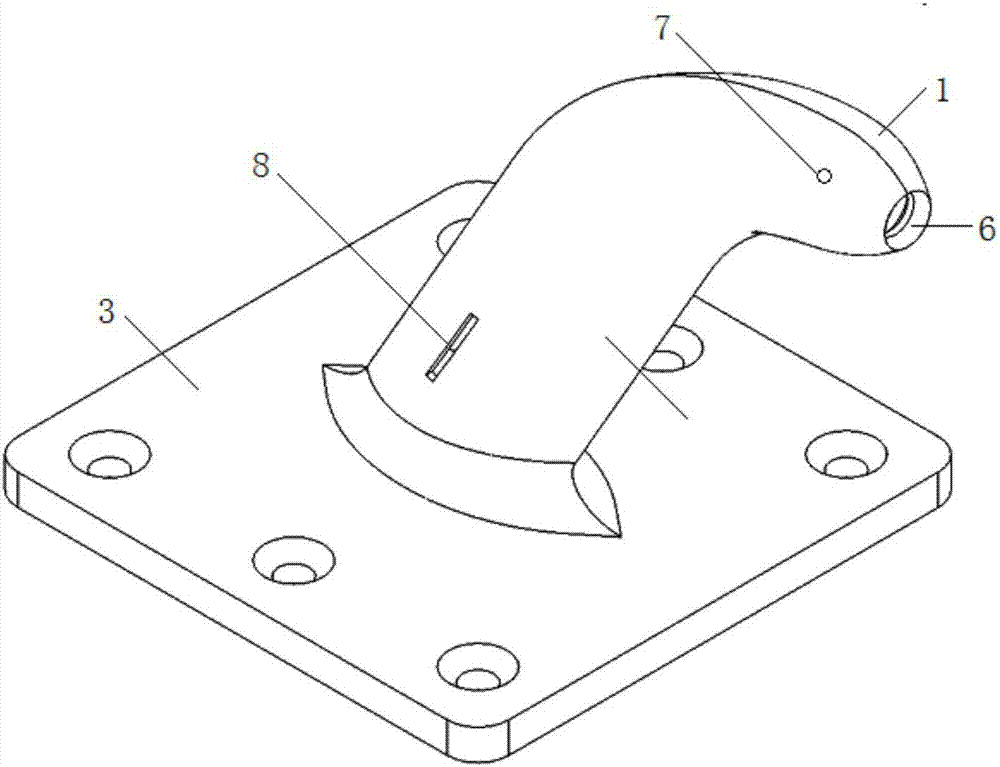

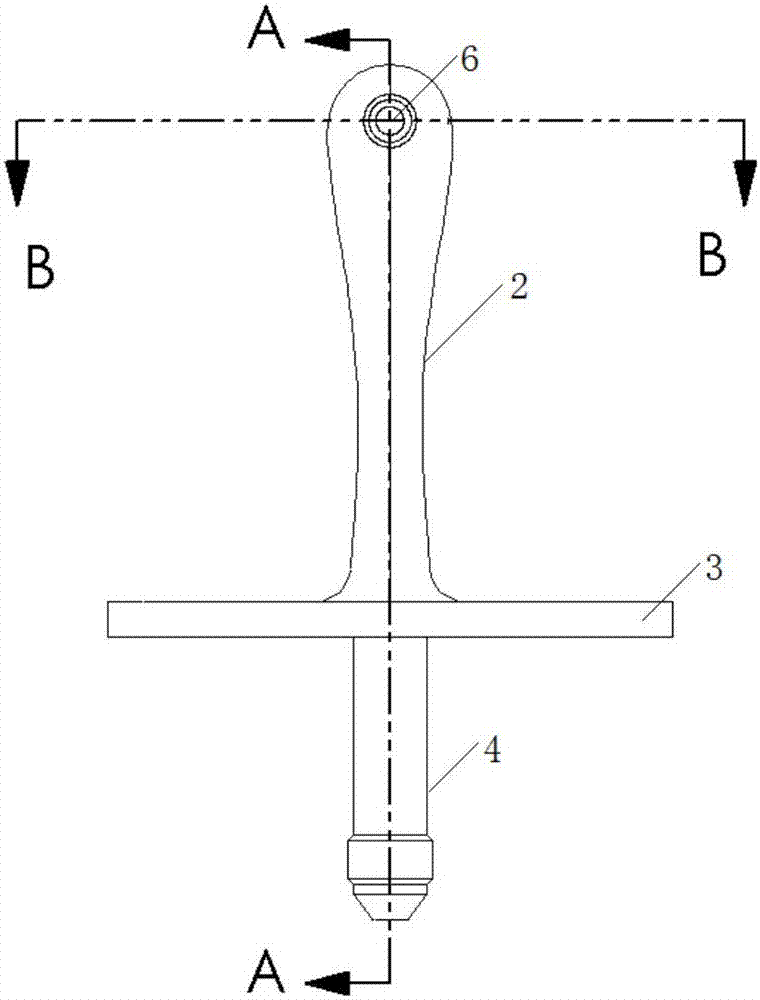

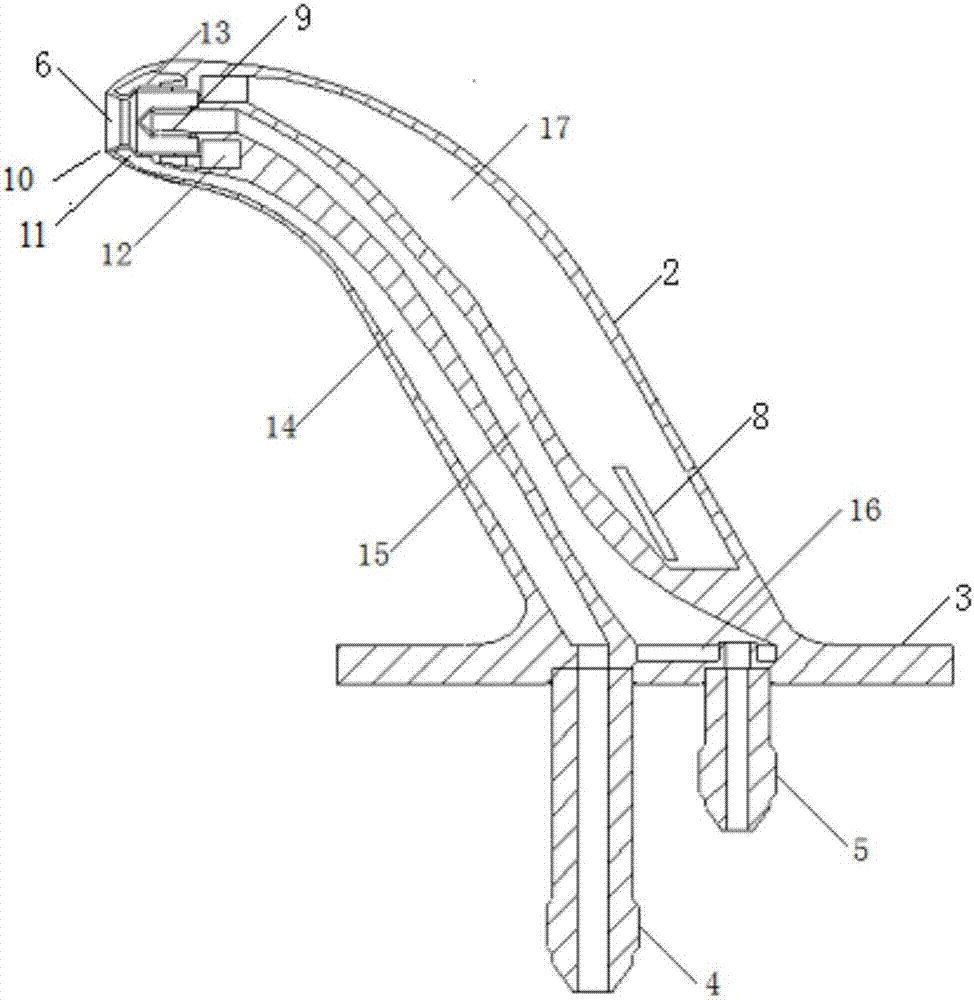

[0019] refer to Figure 1-Figure 4, in the embodiment described below, a hot gas deicing total pressure sensor, including a cone-shaped opening probe 1 with a trumpet-shaped total pressure port 6, fixedly connected to the space velocity that extends obliquely from the mounting base 3 Pipe arm 2 and the hot gas port 4 and total pressure port 5 communicating with the pitot arm (2), wherein the pitot arm 2 is fixedly connected to the square mounting seat with 6 countersunk holes 3, the hot gas port 4 and the total pressure port 5 have flared straight-through pipe joints. The trumpet-shaped total pressure port 6 is located at the end of the cone-shaped opening probe 1, and the elbow of the cone-shaped opening probe 1 is formed with a drainage hole 7, and an exhaust port 8 is provided on the tail of the support arm. The total pressure port 6 adopts a horn-shaped sharp-edged design, and the horn-shaped opening angle is 30°-45°, and the total pressure of the airflow can be felt with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com