Wheat cellulose particle and preparation method thereof

A technology of wheat cellulose and granules, which is applied in the direction of food science, etc., can solve the problem of single function, achieve the effects of less granule additives, improve the condition of gastrointestinal bacteria, and increase the cure rate of constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

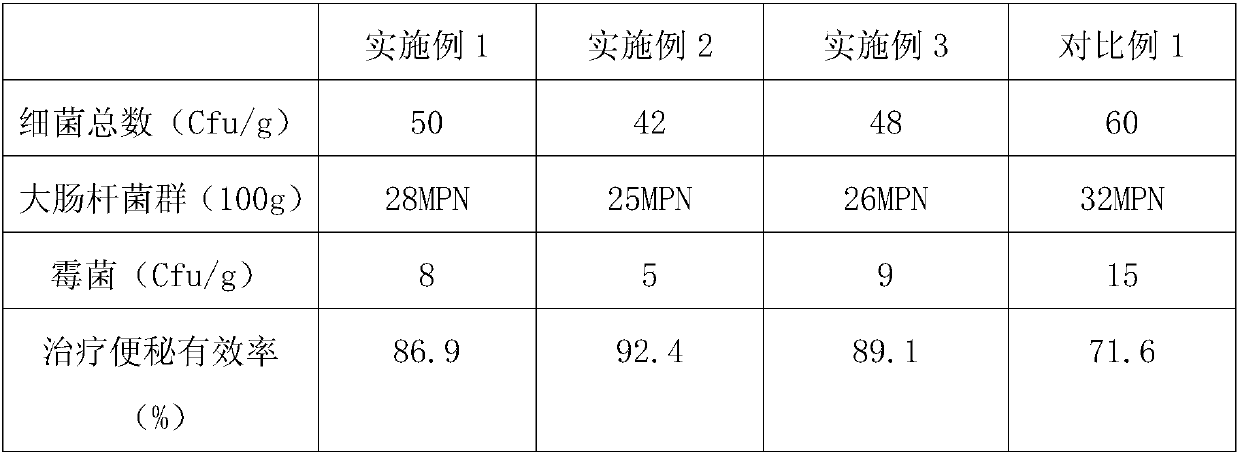

Examples

Embodiment 1

[0017] A wheat cellulose granule, comprising the following components in parts by weight: 120 parts of wheat cellulose, 30 parts of ethanol, 12 parts of probiotic compound, 45 parts of hydrophilic polymer compound, 1 part of maltodextrin, 1 part of chitosan, 5 parts of rice flour, 2 parts of hydrogenated castor oil, 12 parts of fructan, 30 parts of deionized water.

[0018] Wherein, the probiotic compound machine is composed of Bifidobacterium, Lactobacillus Lamans and Lactobacillus acidophilus in a weight ratio of 1:2:2.

[0019] The hydrophilic polymer compound is formed by condensation of polyurethane, ethylene oxide and dextrin.

[0020] The molecular weight of the chitosan is 1500D.

[0021] The preparation method of the above-mentioned wheat cellulose granules comprises the following steps: step 1, weighing each component; step 2, dissolving wheat cellulose in ethanol and distilling under reduced pressure at 30°C for 20 minutes, adding maltodextrin and fructan , after ...

Embodiment 2

[0025] A wheat cellulose granule, comprising the following components in parts by weight: 220 parts of wheat cellulose, 48 parts of ethanol, 35 parts of probiotic compound, 50 parts of hydrophilic polymer compound, 5 parts of maltodextrin, 1 part of chitosan, 7 parts of rice flour, 3 parts of hydrogenated castor oil, 25 parts of fructan, 40 parts of deionized water.

[0026] Wherein, the probiotic compound machine is composed of Bifidobacterium, Lactobacillus Lamans and Lactobacillus acidophilus in a weight ratio of 1:3:2.

[0027] The hydrophilic polymer compound is formed by condensation of polyurethane, ethylene oxide and dextrin.

[0028] The molecular weight of the chitosan is 1800D.

[0029] The preparation method of the above-mentioned wheat cellulose granules comprises the following steps: step 1, weighing each component; step 2, dissolving wheat cellulose in ethanol and distilling under reduced pressure at 35°C for 30 minutes, adding maltodextrin and fructan , after...

Embodiment 3

[0033] A wheat cellulose granule, comprising the following components in parts by weight: 120-240 parts of wheat cellulose, 30-58 parts of ethanol, 12-24 parts of probiotic compound, 45-56 parts of hydrophilic polymer compound 1-8 parts of maltodextrin, 1-3 parts of chitosan, 5-8 parts of rice flour, 2-5 parts of hydrogenated castor oil, 12-28 parts of fructan, 30-50 parts of deionized water.

[0034] Wherein, the probiotic compound machine consists of Bifidobacterium, Lactobacillus Lamans and Lactobacillus acidophilus in a weight ratio of 1:4:2.

[0035] The hydrophilic polymer compound is formed by condensation of polyurethane, ethylene oxide and dextrin.

[0036] The molecular weight of the chitosan is 2000D.

[0037] The preparation method of the above-mentioned wheat cellulose granules comprises the following steps: step 1, weighing each component; step 2, dissolving wheat cellulose in ethanol and distilling under reduced pressure at 50°C for 40 minutes, adding maltodext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com