Chinese wolfberry fruit compound enzymes and preparation method thereof

A compound enzyme and Lycium barbarum technology, applied in the function of food ingredients, food science, application, etc., can solve the problems of poor absorption of nutrients, and achieve the effects of promoting absorption, reducing burden, and facilitating defecation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

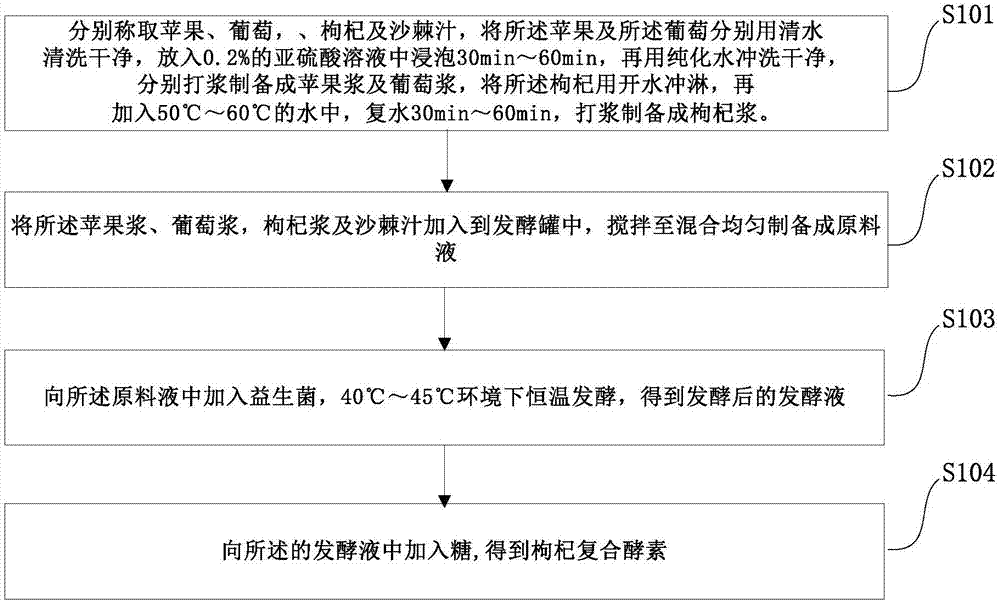

[0042] figure 2 The preparation method of a kind of Lycium barbarum compound ferment shown for the embodiment of the present application, described method comprises the steps:

[0043] S101 Weigh apples, grapes, wolfberry and seabuckthorn juice respectively, clean the apples and grapes with water, soak them in 0.2% sulfurous acid solution for 30-60 minutes, rinse them with purified water, and Beating to prepare apple pulp and grape pulp, rinse the wolfberry with boiling water, add to water at 50° C. to 60° C., rehydrate for 30 minutes to 60 minutes, and beat to prepare wolfberry pulp.

[0044] The weight parts of the apple, the grape, the wolfberry and the seabuckthorn juice are respectively: 25%-40%, 10%-20%, 20%-30% and 20%-35%.

[0045]The embodiment of the present application uses 0.2% sodium sulfite to treat the surface of apples and grapes. On the one hand, sodium sulfite can strongly inhibit the oxidase in apples or grapes, effectively prevent apples and / or grapes fro...

Embodiment 1

[0082] (1) take respectively the apple of 30% weight portion, the seabuckthorn juice of 32% weight portion, the wolfberry of 25% weight portion, the grape of 13% weight portion, after apple and grape are washed clean with clear water, with 0.2% sulfurous acid solution Soak in water for 30 minutes, rinse with purified water, beat for later use;

[0083] (2) Rinse wolfberry with boiling water, then add warm boiling water at 60°C in a ratio of 1:2, rehydrate for 60 minutes, and beat for later use;

[0084] (3) Put apple pulp, grape pulp, wolfberry pulp and seabuckthorn juice into the fermenter, and stir until evenly mixed;

[0085] (4) Add kefir granules according to the addition amount of 0.7‰ of the raw material liquid quality, and place them in a 42°C incubator for cultivation until the end of fermentation;

[0086] (5) Filter with 100 mesh sieves after the fermentation is finished, and take the clarified liquid for subsequent use;

[0087] (6) Add stachyose to the clarified...

Embodiment 2

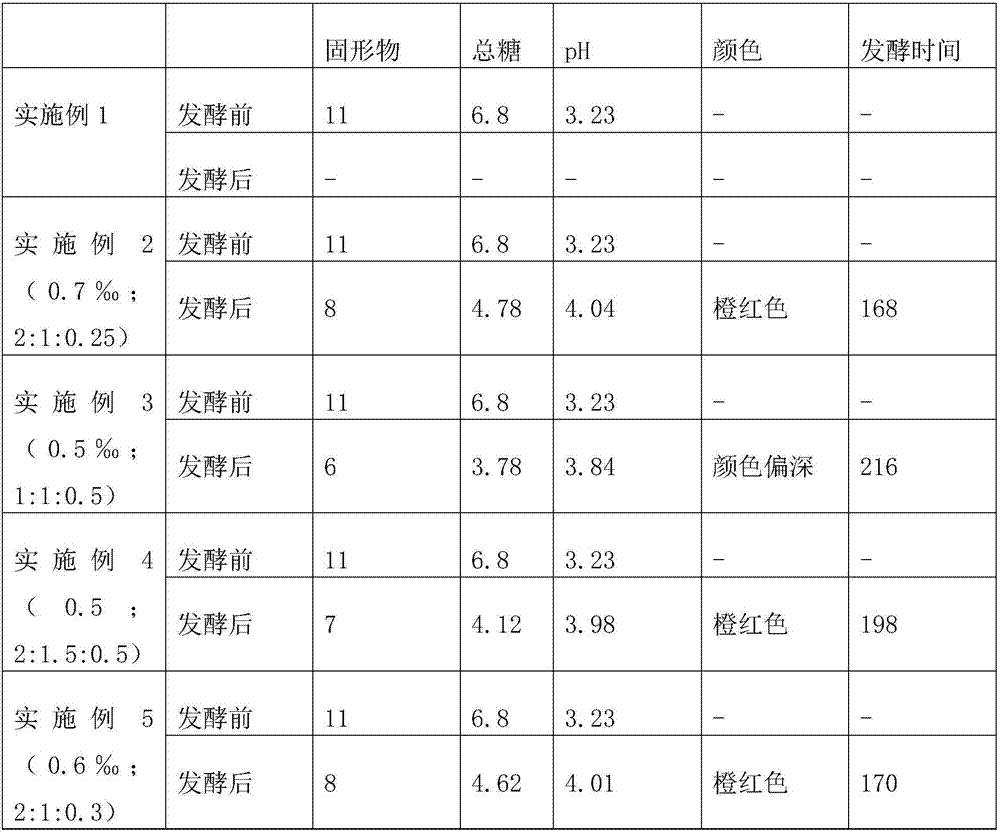

[0089] Repeat Example 1 according to the same steps, however, the kefir granules are replaced by lactic acid bacteria in the kefir granules, bifidobacteria in the kefir granules and yeast in the kefir granules Line of mixed strains, the ratio is 2:1:0.25.

[0090] Experimental results: the solid content of the mixture before fermentation is 11, the total sugar content is 6.8, and the pH value is 3.24. After 168 hours of fermentation, the solid content is 8, the total sugar content is 4.78, and the pH value is 4.04. The product has a mild sour taste , outstanding aroma, orange-red color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com