Flexible composite membrane, preparation method of flexible composite membrane, and display device

A composite film and flexible technology, which is applied in the field of flexible composite film and its preparation, can solve the problems that the research of flexible displays needs to be further deepened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

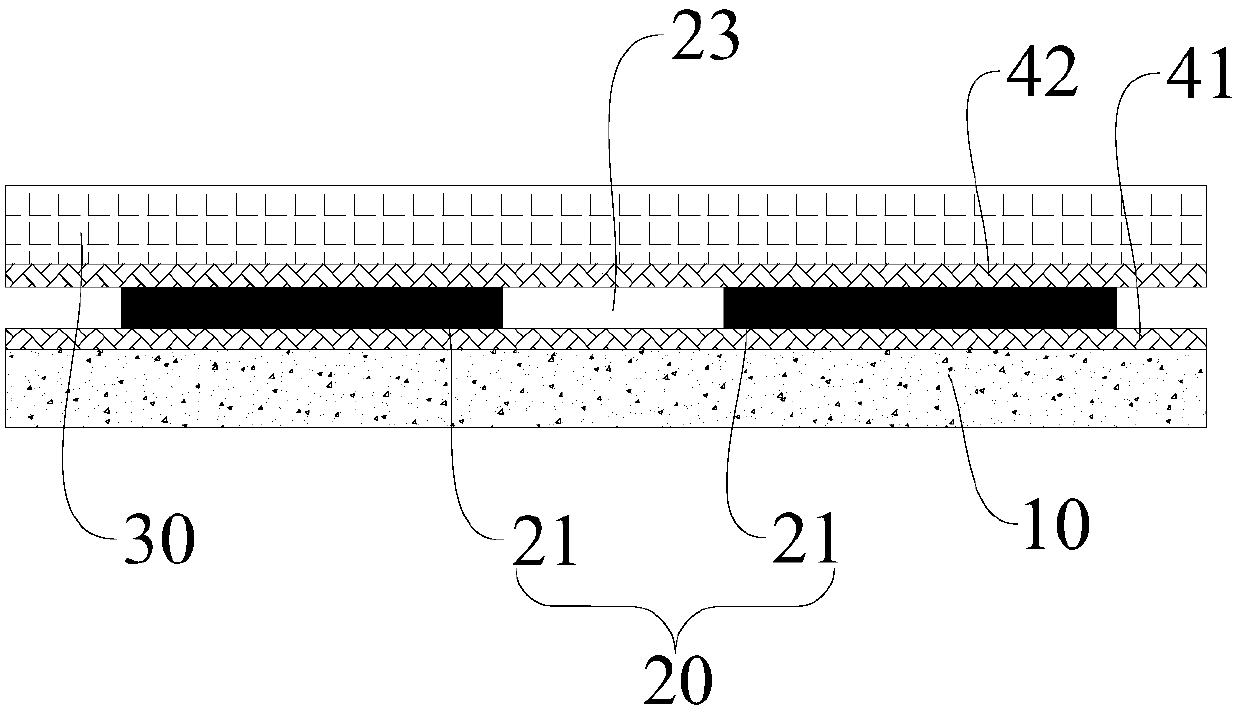

[0072] According to an embodiment of the present invention, the shielding layer may further include an antistatic release film to form a composite shielding layer. The preparation method of the composite shielding layer includes: first applying the conductive adhesive to the antistatic release film by scraping After coating, bake in an oven at 100-150°C and cure for 90-180s to obtain a composite shielding layer, and then bond the side of the composite shielding layer coated with conductive adhesive to the second bonding layer. Therefore, the composite shielding layer can not only support the flexible composite film, but also prevent the conductive adhesive from falling off.

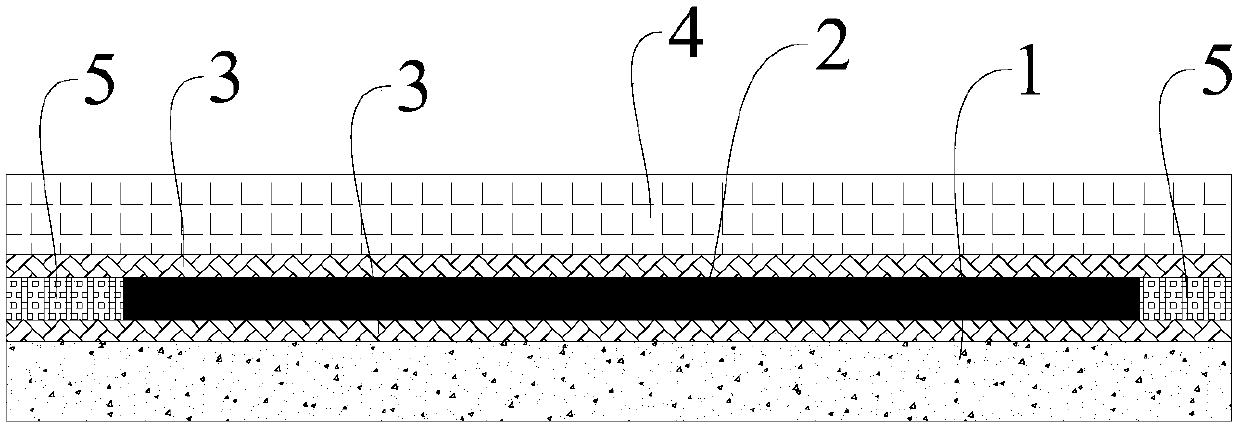

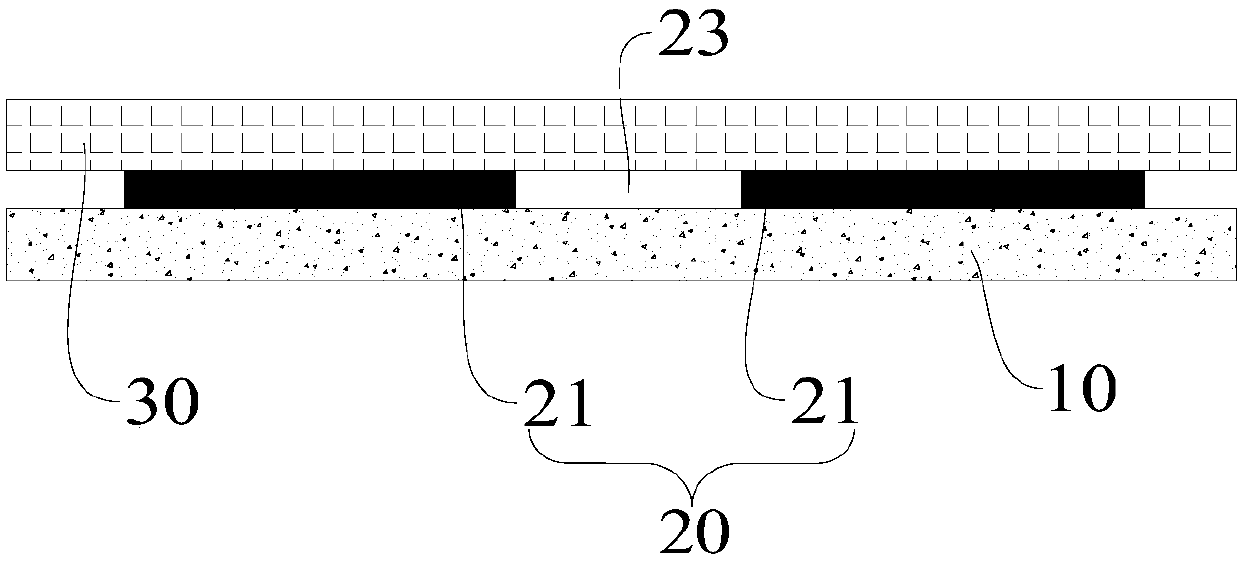

[0073] According to a specific embodiment of the present invention, the method for preparing a flexible composite film includes: attaching the buffer layer on one side of the first adhesive layer, and then bonding the heat sink to the other side of the first adhesive layer; One side of the second adhesive...

Embodiment 1

[0076] The conductive glue forming the shielding layer includes at least one of 60 parts by weight of polyurethane glue, epoxy resin glue or acrylic resin glue and at least one of 30 parts by weight of polypyrrole, polyphenylene sulfide, polyaniline, and polythiophene The mixture, the thickness of the shielding layer is 15 microns; the thickness of the first acrylic glue and the second acrylic glue are both 5 microns, and the adhesive force is 1000gf / mm; the graphite sheet contains two sub-graphite sheets, and the thickness of the graphite sheet is 17 microns, The thermal conductivity in the horizontal direction is 1500W / (m·k), and its length and width are 0.5 cm smaller than the length and width of the first acrylic glue; the thickness of the acrylic foam is 100 microns, and the density is 0.75g / cm 3 . The overall thickness of the flexible composite film thus prepared was 142 microns. The flexible composite film can not only effectively buffer the internal and external impac...

Embodiment 2

[0078] The conductive glue forming the shielding layer includes at least one of 60 parts by weight of polyurethane glue, epoxy resin glue or acrylic resin glue and at least one of 15 parts by weight of polypyrrole, polyphenylene sulfide, polyaniline or polythiophene and 10 parts by weight of iron-zinc alloy powder and 5 parts by weight of copper powder, the thickness of the shielding layer is 15 microns; the thickness of the first acrylic glue and the second acrylic glue are both 5 microns, and the adhesive force is 1000gf / mm The graphite sheet contains two sub-graphite sheets, the thickness of the graphite sheet is 17 microns, the thermal conductivity in the horizontal direction is 1500W / (m k), and its length and width are 0.5 cm smaller than the length and width of the first acrylic glue; Cotton has a thickness of 100 microns and a density of 0.5 g / cm 3 . The overall thickness of the flexible composite film thus prepared was 142 microns. The flexible composite film can not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com